Wiring – Rockwell Automation 21G PowerFlex 750 Series Safe Torque Off User Manual

Page 24

24

Rockwell Automation Publication 750-UM002F-EN-P - July 2013

Chapter 3

Installation and Wiring

Wiring

Important points to remember about wiring:

• Always use tinned copper wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control wires should be separated from power wires by at least 0.3 meters

(1 foot).

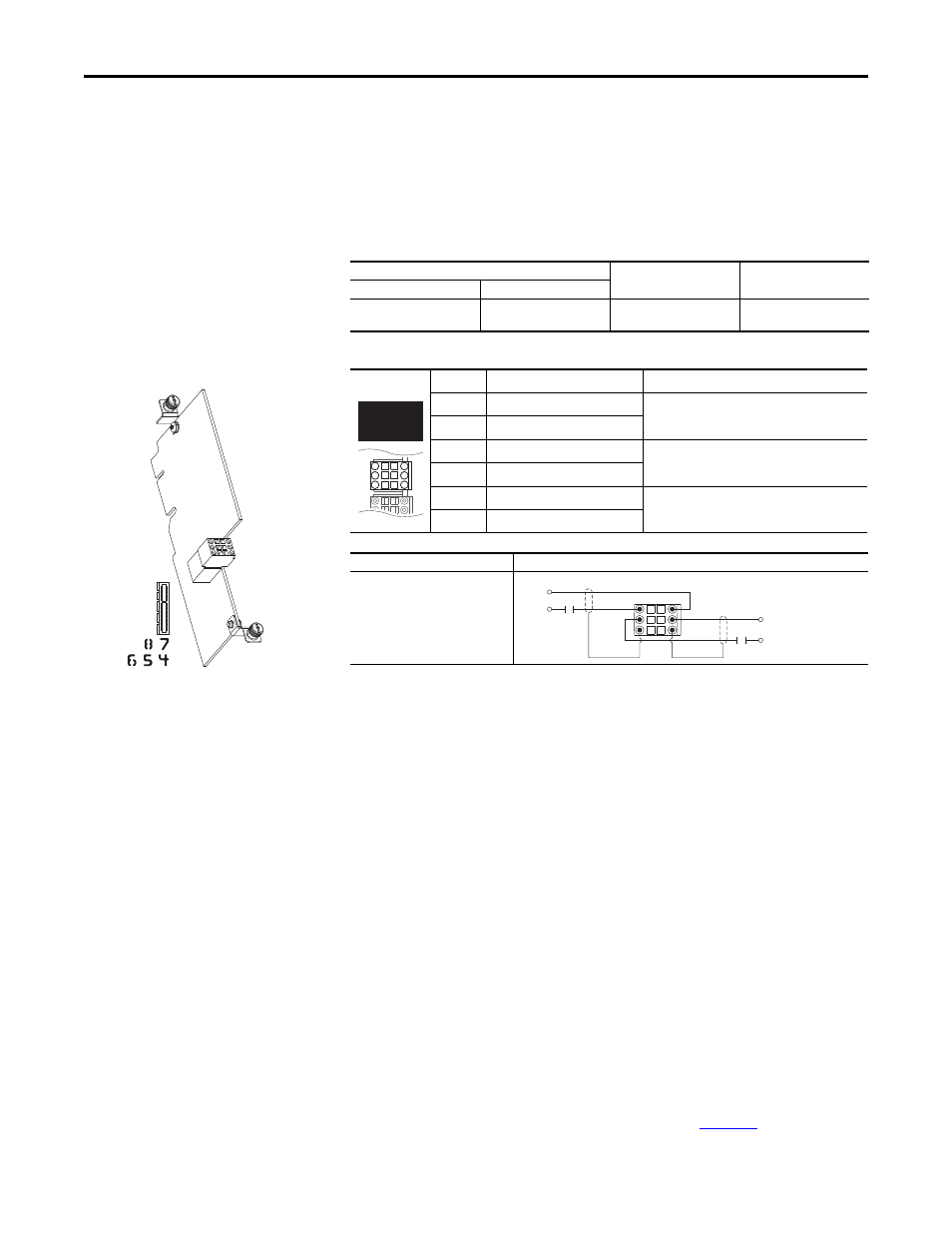

Table 1 - Safe Torque Off Option Terminal Block Specifications

Table 2 - TB2 Terminal Designations

Important Safe Torque Off Option Module Installation Notes

Cabling

• Safety input wiring must be protected against external damage by cable

ducting, conduit, armored cable or other means.

• Shielded cable is required.

Power Supply Requirements

• The external power supply must conform to the Directive 2006/95/EC

Low Voltage, by applying the requirements of EN61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests and one of the

following:

– EN60950 - SELV (Safety Extra Low Voltage)

– EN60204 - PELV (Protective Extra Low Voltage)

– IEC 60536 Safety Class III (SELV or PELV)

– UL 508 Limited Voltage Circuit

– 24V DC ±10% must be supplied by a power supply that complies with

IEC 60204 and IEC 61558-1.

• For planning information, refer to the guidelines in Industrial Automation

Wiring and Grounding Guidelines, publicat

.

Wire Size Range

Wire Type

Strip Length

Maximum

Minimum

0.8 mm

2

(18 AWG)

0.3 mm

2

(28 AWG)

Multi-conductor shielded

cable

10 mm

(0.39 in.)

20-750-S

Terminal

Name

Description

SP+

+24 Volt Safety Power

User-supplied power: 24 volt ±10%

45 mA typical

SP-

Safety Power Common

SE+

+24 Volt Safety Enable

User-supplied power: 24 volt ±10%

25 mA typical

SE-

Safety Enable Common

Sd

Shield

Terminating point for wiring shields when an EMC

plate or conduit box is not installed.

Sd

Shield

Safety Input

Connection Example

Power Supply

SP+

SE+

Sd

SP-

SE-

Sd

SE-

SP+

SP-

SE+

Sd

Sd

Common

+24V

+24V

Common