Rockwell Automation 42DR Intrinsically Safe Sensor User Manual

Page 2

2

To design an effective Intrinsically Safe system, energy sources that enter the

hazardous area must be limited. For electronic controls, energy limiting is

accomplished by controlling the voltages and currents that may enter the

hazardous area. In addition, stored electrical energy in the controls is limited to

levels that cannot cause ignition of a given atmosphere.

An Intrinsically Safe system overcomes the shortcomings of the

“explosion-proof” system and virtually eliminates the probability of explosion by

properly installing Intrinsic Safety Zener Diode Barriers in the safe area.

Intrinsic Safety Zener Diode Barriers must be installed in the power supply

line, the load supply line and when using the current source (PNP) open

collector of the Series 5500, in the signal return line.

Summary of Hazardous Locations

(For full and complete definitions, consult the National Electric Code

publication NFPA No. 70--78.)

Class I

Locations in which flammable gases or vapors

are or may be present in the air in quantities

sufficient to produce explosive or ignitable

mixtures.

Class II

Locations which are hazardous because of the

presence of combustible dust.

Class III

Locations which are hazardous because of the

presence of easily ignitable fibers or flyings, but

in which such fibers or flyings are not likely to be

suspended in air concentrations sufficient to

produce ignitable mixtures.

Division I

Locations which are hazardous concentrations

in the air exist continuously, intermittently, or

periodically under normal operating conditions.

Division 2

Locations which are hazardous concentrations

are handled, processed, or used but are

normally within closed containers or closed

systems from which they can escape only in

case of accidental rupture or breakdown.

Group A

Atmospheres containing acetylene.

Group B

Atmospheres containing hydrogen, or gases or

vapors of equivalent hazard, such as

manufactured gas.

Group C

Atmospheres containing ethyl-ether vapors,

ethylene, or cyclo-propane.

Group D

Atmospheres containing gasoline, hexane,

naptha, benzine, butane, propane, alcohol,

acetone, benzol, laquer solvent vapors, or

natural gas.

Group E

Atmospheres containing metal dust, including

aluminum, magnesium, and their commercial

alloys, and other metals of similarly hazardous

characteristics.

Group F

Atmospheres containing carbon black, coal or

cake dust.

Group G

Atmospheres containing flour, starch, or grain

dusts.

Typical Class I Locations

S

Petroleum refineries and gasoline storage and dispensing

areas.

S

Industrial firms that use flammable liquids in dip tanks for

parts cleaning or other operations.

S

Petrochemical companies that manufacture chemicals from

gas and oil.

S

Dry cleaning plants where vapors from cleaning fluids can

be present.

S

Companies that have spraying areas where they coat

products with paint or plastics.

S

Aircraft hangars and fuel servicing areas.

S

Utility gas plants, and operations involving storage and

handling of liquified petroleum gas or natural gas.

Typical Class II Locations

S

Grain elevators, flour, and feed mills.

S

Plants that manufacture, use, or store magnesium of

aluminum powders.

S

Plants that have chemical or metallurgical processes,

producers of plastics, medicines, and firewoods, etc.

S

Producers of starch or candies.

S

Spice-grinding plants, sugar plants, and cocoa plants.

S

Coal preparation plants and other carbon-handling or

processing areas.

Typical Class III Locations

S

Textile mills, cotton gins, cotton seed mills, and flax

processing plants.

S

Any plant that shapes, pulverizes or cuts wood and creates

sawdust or flyings.

Note: Fibers and flyings are not likely to be suspended in the

air, but can collect around machinery or on lighting fixtures

and where heat, a spark or hot metal can ignite them.

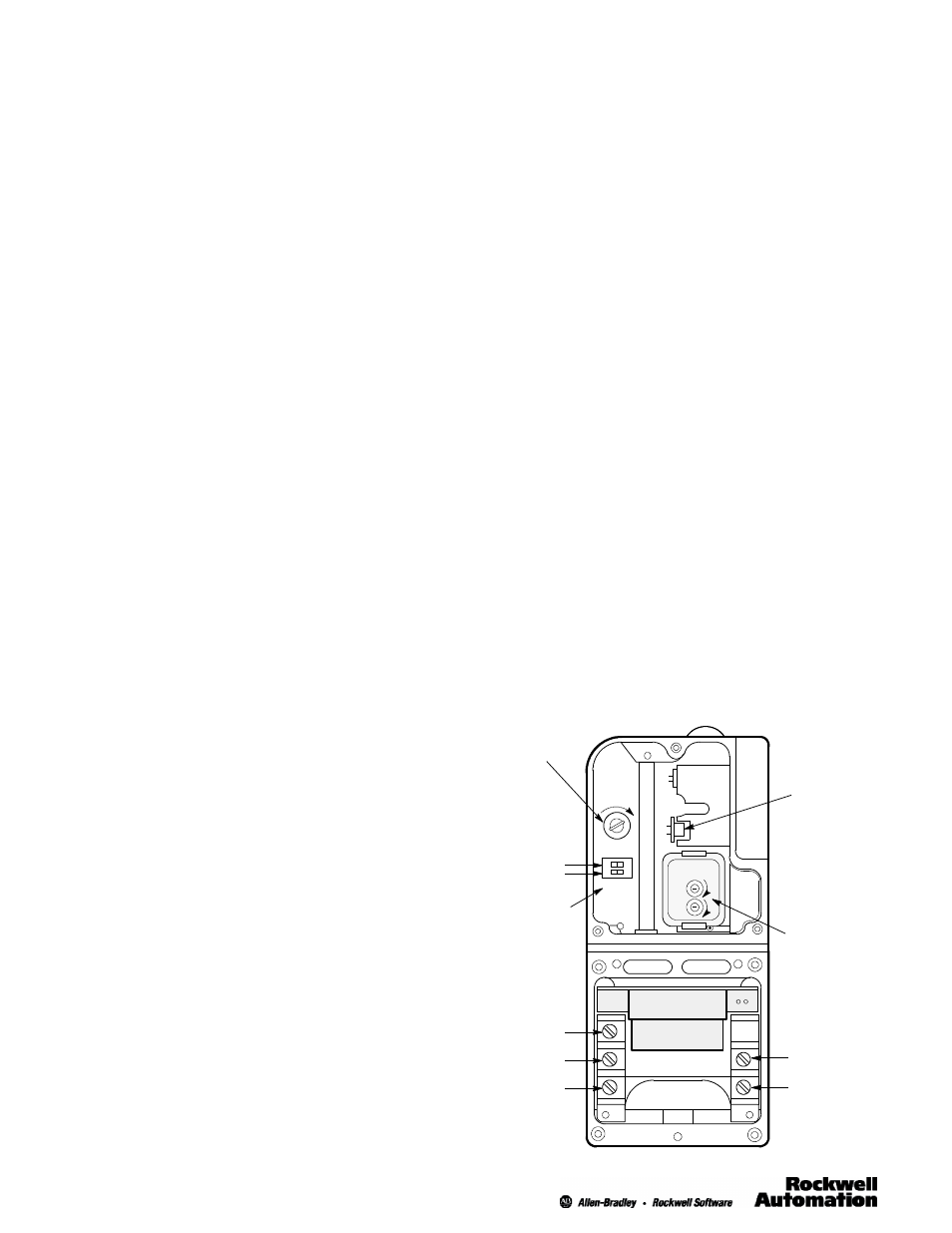

Series 5500 Type 42DRP Photohead and

42DTB Power Base with Covers Removed

Sensitivity

Adjustment

Light/Dark

Switch

Visible

Alignment

Indicator

Short Range

Long Range

Shutter

(on 42DRP

only)

PNP & NPN

Output

Circuitry

3

2

1

( + )

( - )

See page 7, for actual connection diagrams.

SENS

LO HI

DK LT

TWO - WAY

TIME DELAY

O

N

O

F

F

Low - High

Sensitivity

Switch