Rockwell Automation 42DR Intrinsically Safe Sensor User Manual

Rockwell Automation Equipment

Installation/Configuration Instructions for 42DR

Intrinsically Safe Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

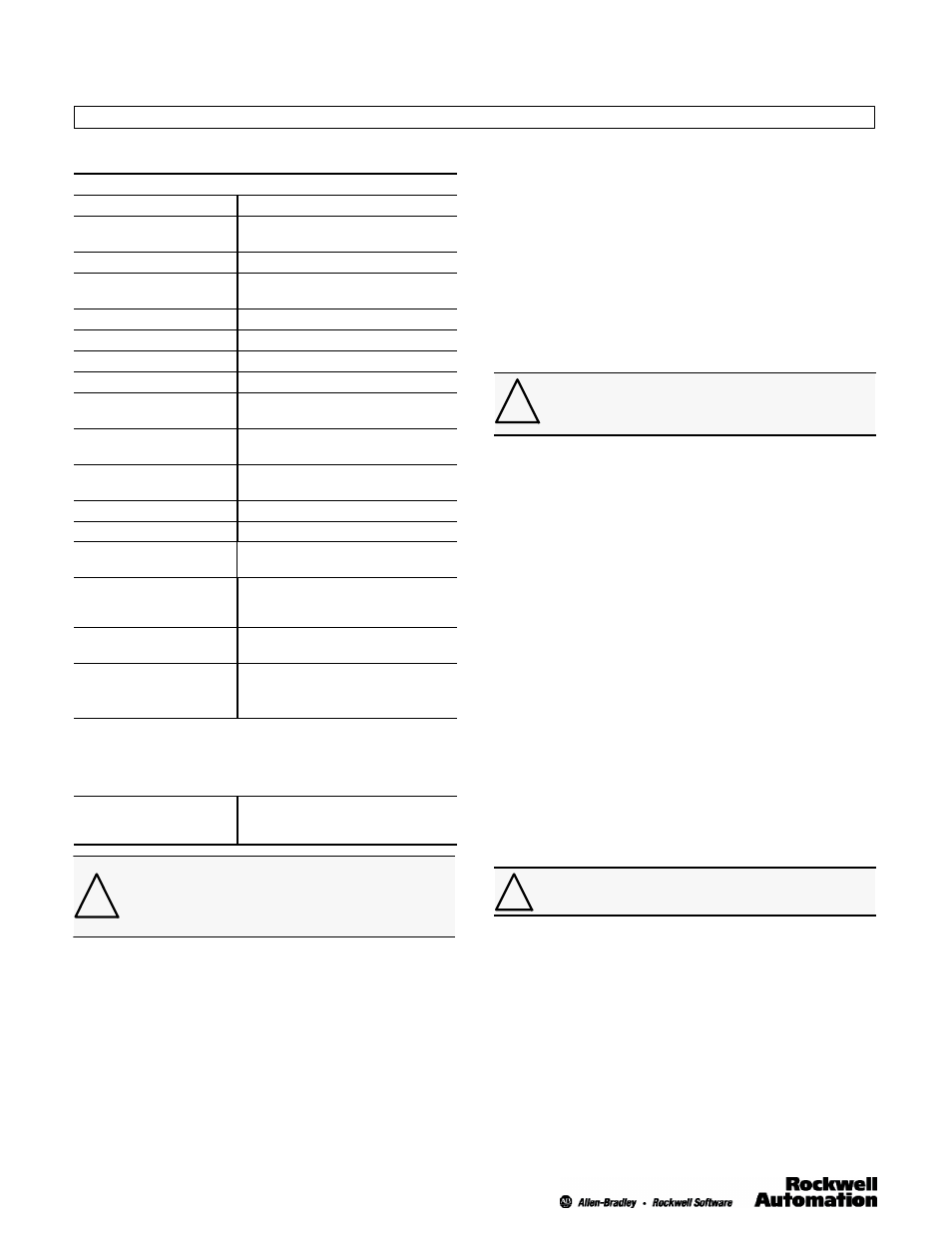

Specifications

Normal Operation Requirements

Voltage Supply

13--29.5V DC

Supply Current

26mA max (output energized) at 13V DC

30mA max (output energized) at 29.5V DC

Response Time

1ms

Dual Outputs

1 NPN open collector (current sink)

1 PNP open collector (current source)

Output Ratings

20mA, 29.5V DC maximum

Turn On Pulse Suppression

Yes

Light/Dark Energized Option

Yes

Reverse Polarity Protection

Yes

Output Overvoltage

Protection w/ Barriers

Yes

Field of View

Type 42DRU Reflex

2.5

Type 42DRP Proximity

3

Sensitivity Adjustment

Selectable by LOW (L)—HIGH (H) switch.

Covers full range of operating distances.

Ambient Temperature

--40F to 150F (--40C to 65C)

Relative Humidity

90%

Rated Operating Distances

All operating distances are with LOW (L)—

HIGH (H) switch in the HIGH (H) position.

42DRU- 5500

3 Dia. Reflector #92--39

1 to 30

1.25 Dia. Reflector #92--47

1 to 20

0.625 Dia. Reflector #92--46

1 to 15

42DRU- 5700

3 Dia. Reflector #92--39

6 to 15

1.25 Dia. Reflector #92--47

6 to 8

42DRP- 5500

White Paper

Distance Discrimination Range

Short Range (SR)

Long Range (LR)

1

5

5 to 16

16 to 5

Distance differential

between surface to be detected and background is defined

as the increase in distance required to de-energize the output, measured from the

point of energization:

Min. differential 10%

6 to 16

Min. differential 20%

2 to 5

42DRA- 5500

Operating distance depended on the choice

of lens or Fiber Optic Cable. See Bulletin

PA- 8306, PA- 8307, and PA- 8401.

Attention: Installation in hazardous environment

locations shall be made according to

ANSI/ISA -- RP 12.6 and other applicable

codes and standards.

!

Features

S

For use in Class I, II, III; Division 1, 2; Group A, B, C, D, E,

F, G hazardous locations with Intrinsic Safety Zener Diode

Barriers.

S

Reflex, polarized reflex, proximity, and special function

control models.

S

Rated operating ranges

-- Reflex 1 to 30 (0.03m to 9m)

-- Polarized Reflex 6 to 15 (0.15m to 4.5m)

-- Proximity 0 to 5 (0 to 1.5m).

S

Quick-Disconnect (QD) reduces downtime. No disruption of

alignment or wiring.

Features (continued)

S

Photohead and terminal base are specially keyed to

prevent improper installation of non-intrinsically safe

equipment in a hazardous location.

S

Terminal base for input voltages 13 to 29.5V DC eliminates

needs for separate junction box.

S

Entity approval:

-- Vmax = 29.5V

-- Imax = 107mA

-- Ci = 0F

-- Li = 0H

Attention: These parameters must be adhered to. If

not, injury may be caused to person or

property.

!

S

Control input parameters

-- Supply voltage 13 to 29.5V DC

-- Supply current, 26mA max. at 13V DC, 30mA max. at

29.5V DC

S

Plug-in Photohead contains functional electronics and

optics.

S

Thick film microcircuitry for quality and reliability.

S

Adjustable input sensitivity.

S

RF interference protected.

S

No false turn-on pulse.

S

Synchronous detection circuitry avoids ambient

interference.

S

Switch selection for light or dark operation.

S

Dual open collector outputs provide current sink (NPN) and

current source (PNP) capabilities.

-- Load voltage 29.5V DC max.

-- Load current 20mA max.

S

Response Time: 1ms

S

LED alignment indicator: Visible 360

S

NEMA 4X corrosion resistant, high impact housing.

S

UL Listed.

Attention: Substitution of components may impair

intrinsic safety.

!

Why Intrinsically Safe

Explosion prevention is a prime consideration in plants and facilities containing

hazardous atmospheres where “explosion-proof” housings are used.

The main fault with the “explosion-proof” housing system is that a single human

error could create a light explosion probability. Such occurrences as, failing to

tightly replace covers on “explosion-proof” housings, failing to shut off the power

before removing the cover of such a housing, and damaging the machined

surfaces of such covers are all prime examples.

Intrinsically Safe systems are now recognized as a more highly desirable

means of providing automated control functions in explosive environments. The

technique relies on the inherent parameters of electronic circuits, so that no

energy can be released under normal or abnormal operating conditions, of

sufficient magnitude to ignite a specified atmospheric mixture.