Aligning the fiber optic cable head (a--b #60 4), Wiring the sensor – Rockwell Automation 42QA ColorSight Series 9000 Photoelectric Sensors User Manual

Page 9

ColorSight Series 9000 PHOTOSWITCH

R

Photoelectric Sensor

9

75027--031--01(A), November 1999

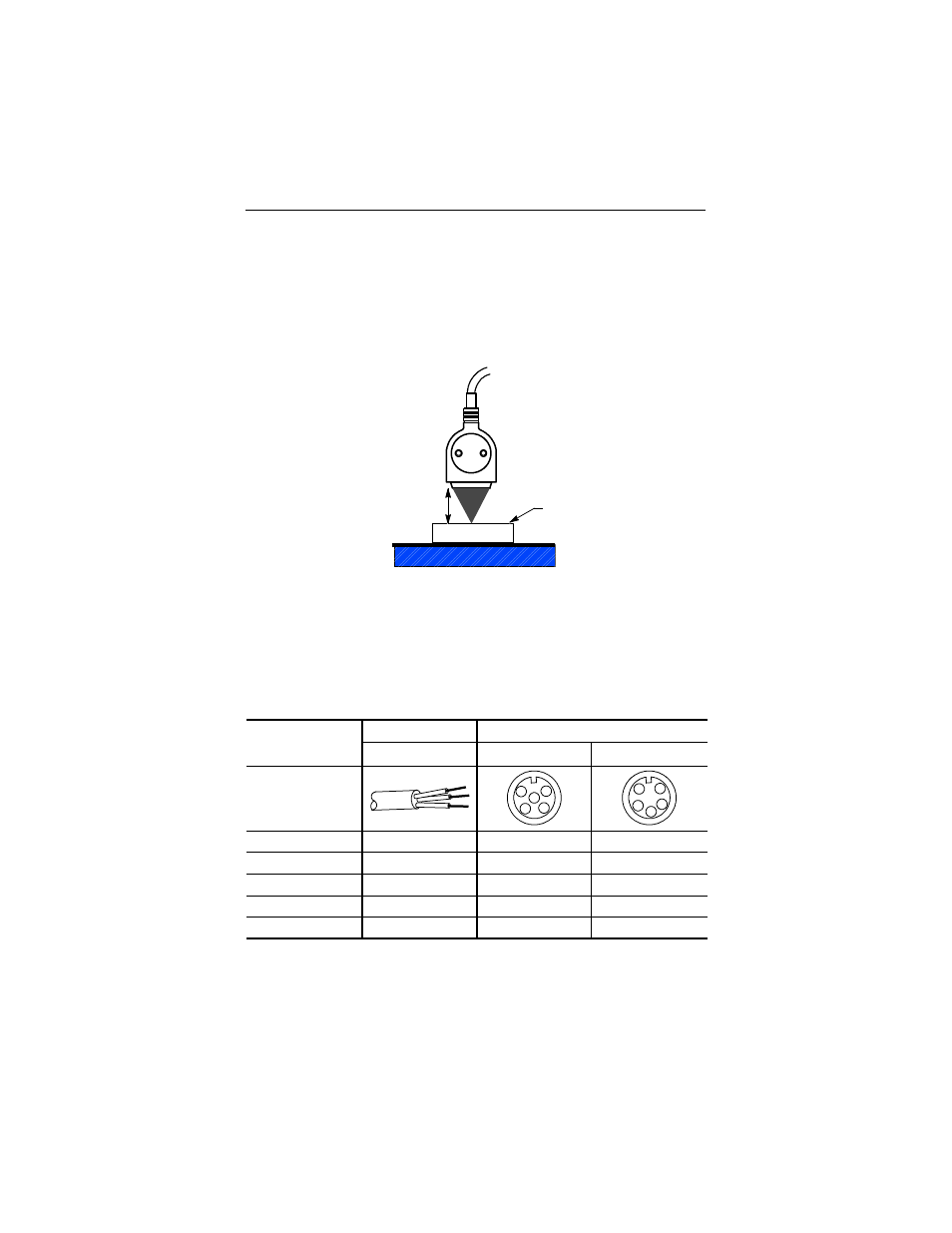

Aligning the Fiber Optic Cable Head (A--B #60--2694)

The head assembly should be positioned and securely fastened so that

the lens is 27mm (1 1/16in) from the target to be sensed. When operating

the sensor in COLOR ONLY mode this tolerance should not exceed

+/-- 3mm (1/8in). For high precision color discrimination applications using

the COLOR PLUS INTENSITY mode, the tolerance can be no more than

+/-- 0.75mm (1/32in).

Target

Distance

plus tolerance

Wiring the Sensor

Models of ColorSight are available in one of three different connection

types as identified in the following table. Allen-Bradley recommends the

use of the 889 Series of cordsets and patchcords on the quick-disconnect

models. All external wiring should conform to the National Electric Code

and all applicable local codes.

Designation

Lead Color

Pin Assignment

2m Cable

5-pin Micro QD

5-pin Mini QD

1

3

2

4

5

1

3

2

4

5

V+ or V--

Brown

1

4

V-- or V+

Blue

3

2

Signal output

Black

4

1

Fault output

Orange

5

3

Learn/Gate input

White

2

5

Polarity of supply voltage defines sensor output type –i.e. PNP or NPN

PNP when brown lead connected to V+ and blue lead connected to V--

NPN when brown lead connected to V-- and blue lead connected to V+

Function determined by selector switch S6