Cleaning the nozzle – Afinia H479 3D User Manual

Page 32

Afinia H-Series 3D Printer User’s Manual

32

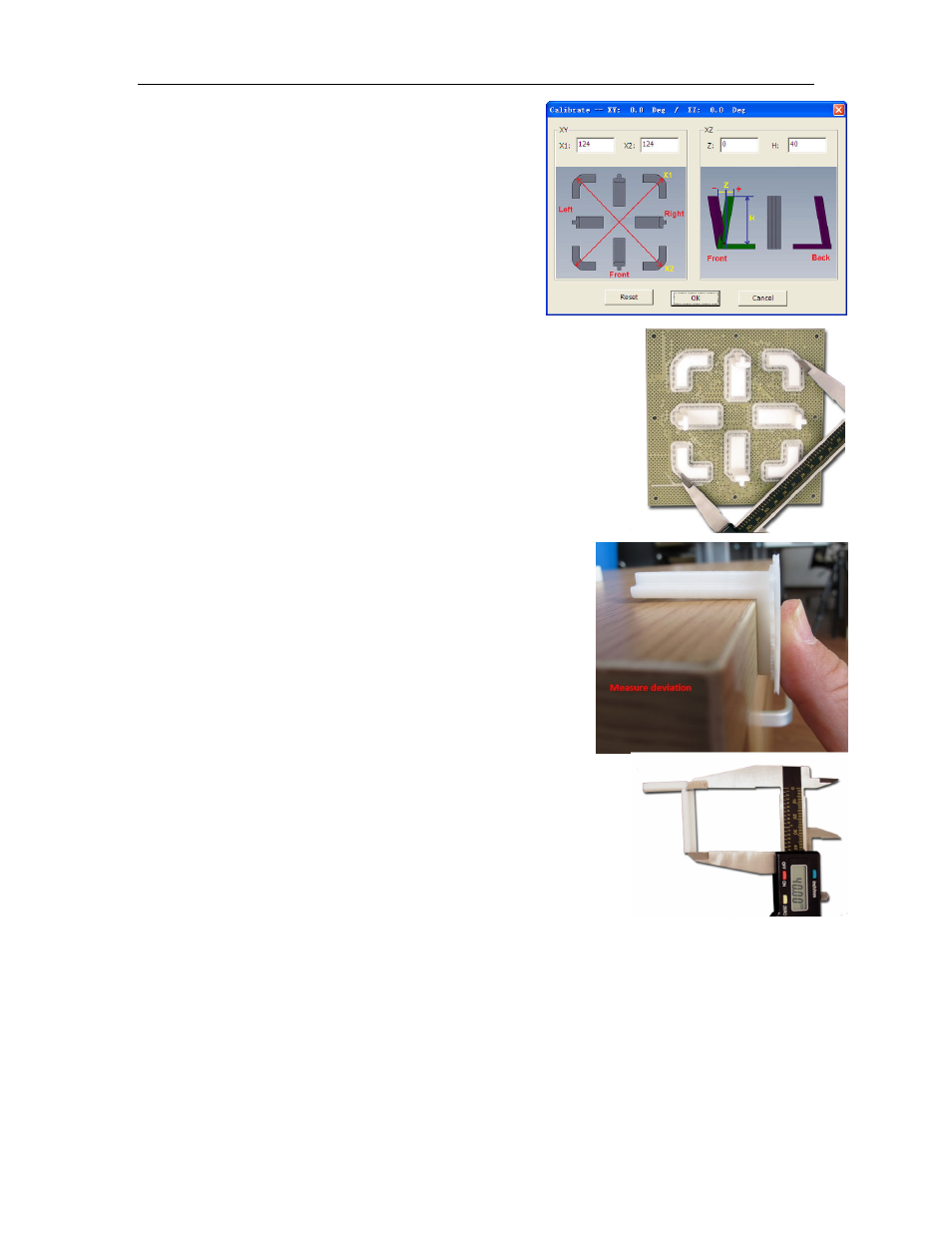

Open the Calibrate dialog from the 3D Print menu.

Measure the X1 and X2 length, as shown in the pictures

below.

IMPORTANT NOTE: Before you enter any new

calibration values, always click the Reset button,

otherwise the new values get added to the old ones.

Before you enter any new values, the bar at the very top

of the screen should read: XY: 0.00 deg / XZ: 0.00 deg.

Measure the calibration print from front left to rear right corners of the

printed parts on the platform to determine the X1 measurement, and

the rear left to front right to determine the X2 measurement.

Be sure that you are not including the raft or support material when

taking these measurements!

Enter the measured X1 and X2 values into the appropriate boxes.

Next, carefully remove the Front Center ‘L’ shaped component

from the platform and check the inside angle. If it is not 90º,

measure the exact distance in millimeters that the end of the

long arm of the part would need to move to get the angle to be

90º and enter that distance into the Z box. If the angle is less

than 90º, the value to be put into the Z box will be a positive

value. If the angle is more than 90º, the value to put into the Z

box will be a negative value. For example, if the end of the

long arm is 1.3 mm above the surface, enter

-1.3

in the Z box.

Finally, measure the long arm of the Front Center component from the

inside of the angle to the end, which should be 40mm at full scale. Enter

the exact measured value into the H box of the Calibrate dialog box.

Click OK to record all these values and exit the calibration window.

Cleaning the nozzle

After a lot of printing, the nozzle may be covered with a layer of oxidized filament material. When

the printer is printing, this oxidized material may melt on the nozzle, and may create discolored

spots in the model or even clog the nozzle. To avoid this you need to regularly clean the nozzle.

Preheat the nozzle as the first step in order to melt the oxidized filament. Click the To Bottom

button on the Maintenance dialog box, and then click the Extrude button. Wait until the material

is finished extruding, then remove any extruded filament from the nozzle.

Use a heat-resistant material such as 100 percent cotton cloth or soft paper and a pair of pliers.

With the material between the pliers and the nozzle, apply gentle pressure with the pliers and turn

the pliers to remove the oxidized filament material. Do not apply heavy pressure!

Checking the X1 Measurement