Operating procedures – Yamato Scientific DVS602 Constant Temperature Drying Oven User Manual

Page 25

23

4. Operating procedures

Preparing a program

Program

operation

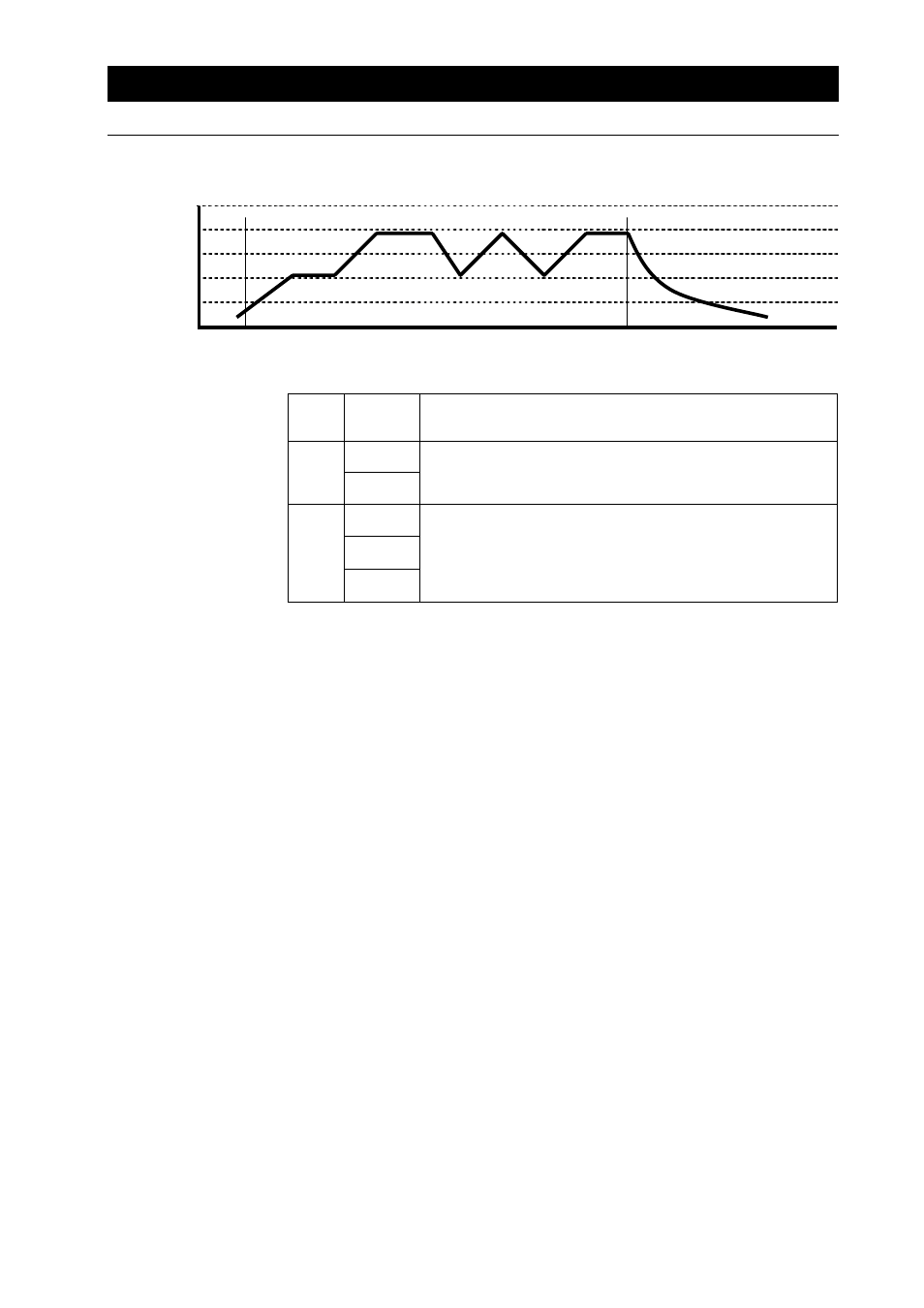

Used when you want to “operation at an increased or decreased

temperature according to specific time.”

Temp

.

△Program operation start

△Operation end Time

Up to six patterns of programs can be stored and input.

Preparing type

PrG1

―

One pattern of a program consisting of up to 30 steps can

be made.

PAt1

PrG2

PAt2

Two patterns of a program consisting of up to 15 steps

can be made.

PAt1

PAt2

PrG3

PAt3

Three patterns of a program consisting of up to 10 steps

can be made.

Before inputting a

program

A program pattern must be registered (input) beforehand to start a

program operation.

① Confirm the number of steps, temperatures for each step, and time

on the program preparation sheet on pages 29 ∼ 30 in the

operation manual.

② Confirm the heating and cooling capacity of the device. Time

needs to be set within the heating and cooling capacity of the

device.

For a device having a cooling or heating capacity of 3℃ for every

ten minutes, for example, it requires about 35 minutes to lower or

raise by 10℃ from the given temperature.

③ Make sure that the controller has an unused pattern that meets the

number of steps to be programmed.

However, when you want to use the repeat function, the number

of steps to be repeated can be deducted from the number of

steps for the unused pattern.

Useful function

You can use the useful repeat function when you want to repeat the

same program steps. See page 28 for how to use the repeat

function.