USG Compässo Standard Suspension Trim System User Manual

Compässo, Standard suspension trim system, Tip sheet

Compässo

™

Standard

Suspension Trim System

Before beginning installation of the C

OMPÄSSO

™

Standard Ceiling System, check the enclosed bill of materials to

ensure that all parts are present and undamaged. Read all installation instructions first and familiarize yourself

with the system’s components. This is extremely important because parts will become permanently damaged if

they are installed incorrectly! To help with identification, all parts are poly-bagged. This is to be used with IC464

General Installation Guide

Tip Sheet

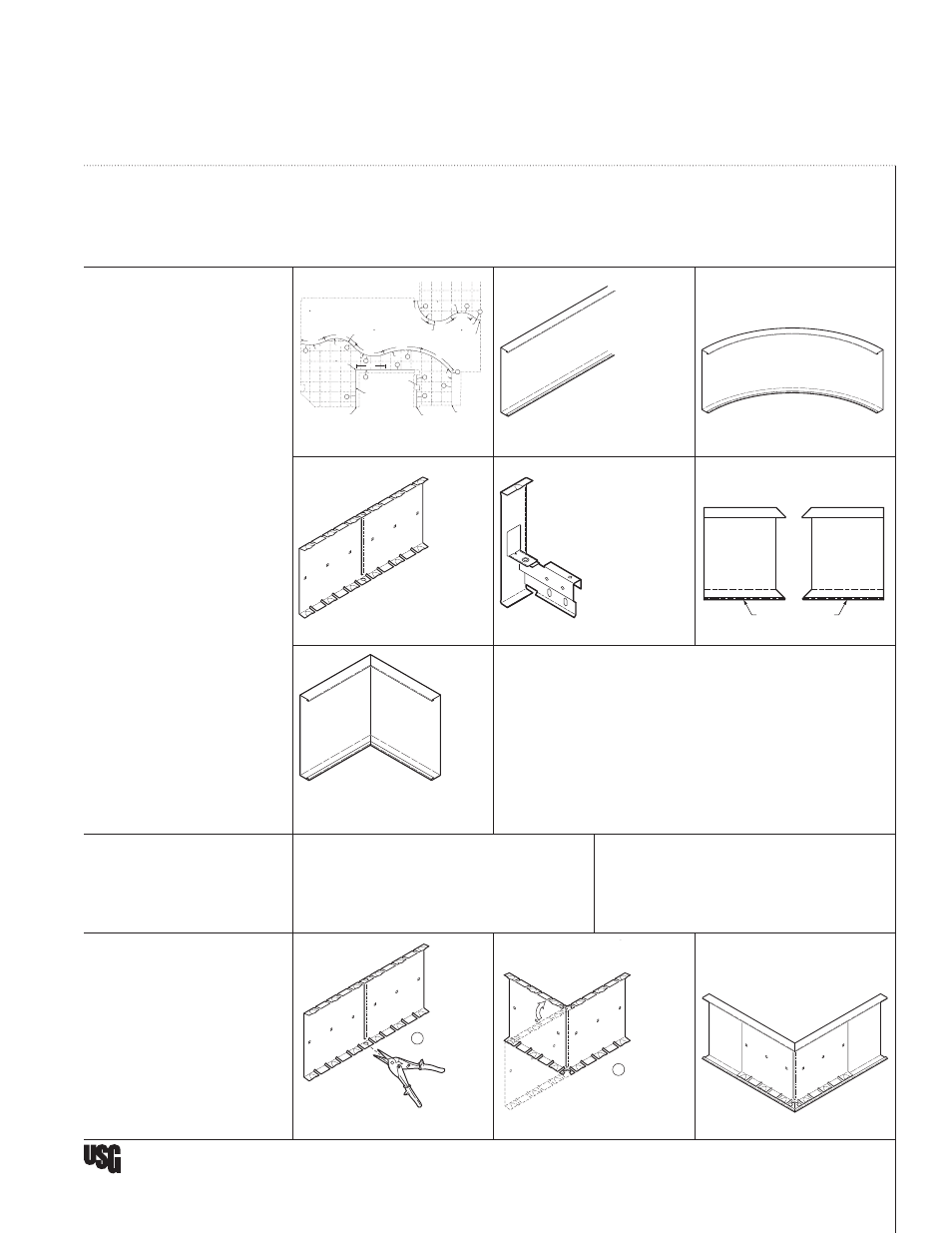

Parts and Components

May include some or all of the following

65.80

65.80

79.97

43.24

77.72

72.43

69.50

corner splice plate (bend 90)

R81

R54

R63

R135

R47

R42

R49

field cut

field cut

field cut

field cut

field cut

finish face

finish face

finish face

37.15

37.15

142

1

2

3

4

6

7

8

9

10

11

11

11

5

11

Bill of Materials (BOM) and

Reflected Ceiling Plan

Suspension Trim—Straight

(available in 2-1/4", 4", 6", 8", 10", 12" widths)

Suspension Trim – Curved

(available in 2-1/4", 4", 6", 8", 10", 12" widths)

4" Splice Plate and Temporary Splice Plates

Attachment Clips

inside corner trim pieces

Inside Corner Trim Pieces

90° Outside Corner (4" x 4")

Outside corners are delivered with the

system as one piece, mitered and formed.

Splices

C

OMPÄSSO

Temporary Splice

Temporary splices are used to keep the system together

when marking and cutting the grid to the appropriate lengths.

Temporary splices are made in the field by cutting permanent

splice plates in half.

C

OMPÄSSO

Permanent Splice

The permanent splice is 6" long and is used only after the grid is

cut and attached to a C

OMPÄSSO

section. Permanent splices are

very difficult to remove once installed.

Inside Corner Splice Plate

Inside corners are assembled from two

mitered sections of C

OMPÄSSO

and one

corner splice plate.

1. snip top and bottom

flange at center

2. fold to desired

angle along crease

A. Snip splice.

1. snip top and bottom

flange at center

2. fold to desired

angle along crease

B. Fold splice at 90 degrees.

C. Assemble inside corner.