What you’ll need, Requirements, If waterproofing is desired, use d – USG Durock Cement Board User Manual

Page 3: Tile membrane product information

What You’ll Need

.........................................................................................................................................................................................

...............................................................................................................................

................................................................................

.........................................................................................................................................................................................

...............................................................................................................................

................................................................................

Requirements

Floors 1/4", 1/2", 5/8"

thickness

– Subfloor should be minimum 5/8"

exterior-grade OSB or plywood.

Countertops 1/4", 1/2", 5/8"

thickness

– Minimum 3/4" exterior-grade

plywood base.

– Cover base with D

urock

™

brand

tile membrane, 15 lb. felt or 4-mil

polyethylene and attach with 1/4"

galvanized staples.

Walls and Ceilings 1/2" and 5/8"

thickness only

– Maximum stud spacing: 16" o.c.

Maximum allowable deflection,

based on stud properties only,

L/360. Maximum fastener

spacing: 8" o.c. for wood and

steel framing; 6" o.c. for ceiling

applications.

Waterproofing

If waterproofing is desired, use

D

urock

tile membrane. See USG

literature piece CB492 for

D

urock

tile membrane product

information.

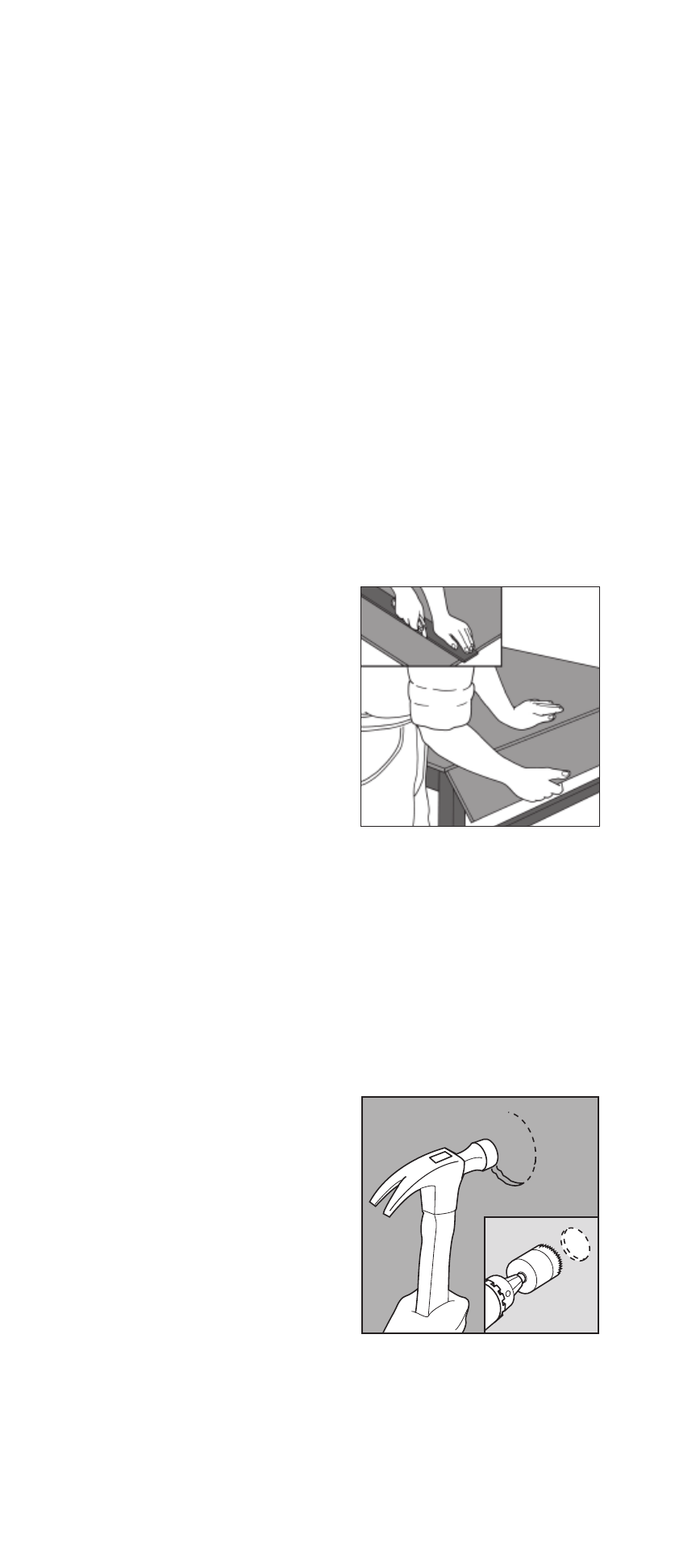

Cutting

D

urock

panels should be cut to

size with a knife and straight edge.

A power saw should be used

only if it is equipped with a dust

collection device. Always wear a

NIOSH/MSHA approved mask and

eye protection when cutting

D

urock

panels.

– Utility knife: Using a straight

edge, score panel face with

utility knife and cut through

glass-fiber reinforcing mesh,

then snap and cut backside mesh

to break cleanly. Use a rasp to

smooth any rough edges.

– Power saw: Use a low-RPM

portable saw with 3-1/2"

carbide-tipped blade. To make

cutouts for pipes and fixtures,

use utility knife to cut through

mesh on both sides of panel and

punch out with a hammer from

back side. Or, use an electric drill

with a hole-saw bit.

WARNING: Dust can contain silica.

Prolonged breathing can cause

lung damage and cancer. See

MSDS for more information.

3

.........................................................................................................................................................................................

...............................................................................................................................

................................................................................