Preparation installation of tile membrane – USG Durock Tile Membrane User Manual

Page 4

4

Preparation

Installation of

Tile Membrane

1. Ensure that substrate is clean,

even, flat, designed to support

ceramic tile, and properly

installed according to manu-

facturers’ specifications.

2. Substrate must be free

of sealers, waxes, bond

breakers, dust and dirt.

3. If D

urock

tile membrane is

installed directly over a wood-

based subfloor, ensure that

all fasteners are seated cor-

rectly and there are no uneven

joints. Sand or fill if necessary.

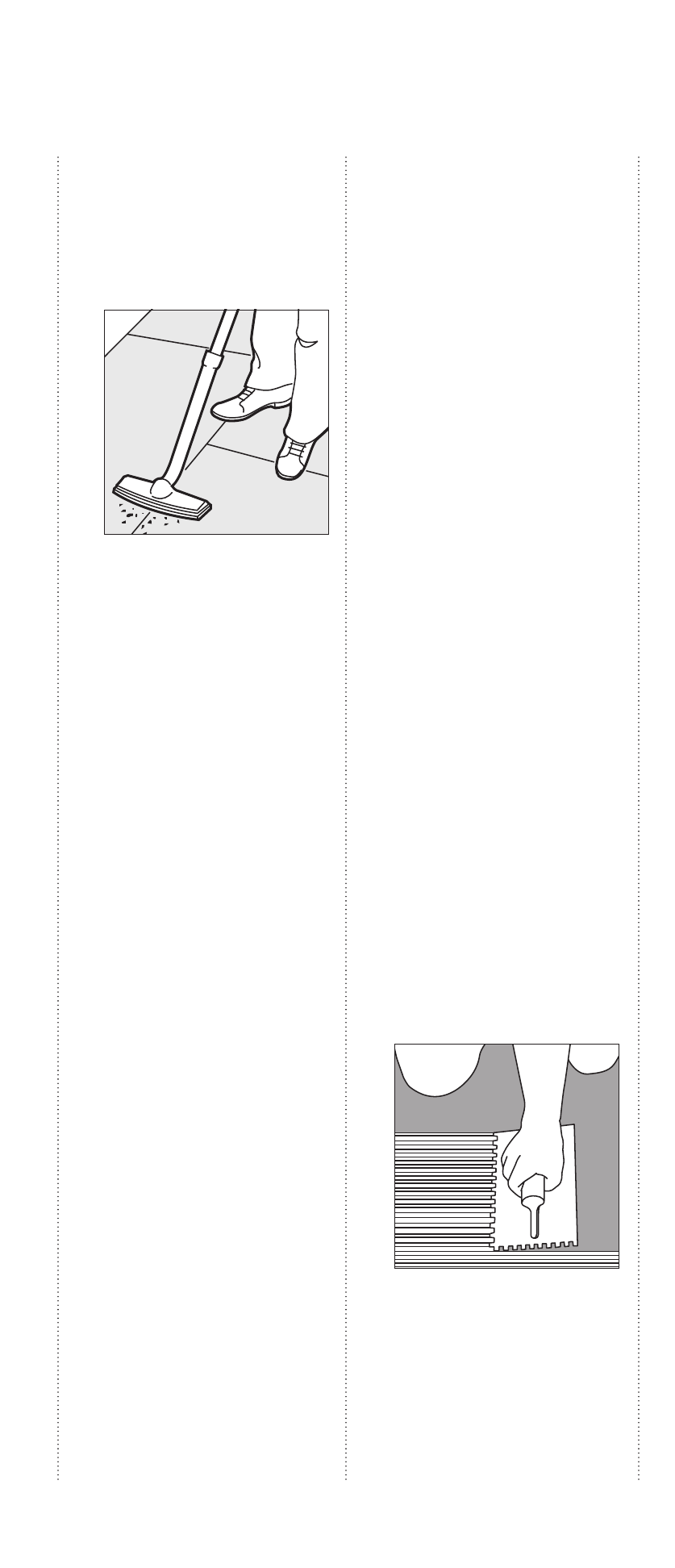

1. Precut the full width of mem-

brane to provide a tight fit to

the perimeter of the room.

2. Spread adhesive over an area

the full width of the sheet and

as far as can be comfortably

reached.

– For D

urock

tile membrane

adhesive, use a 3/89-nap

paint roller or a 1/169 U-notch

trowel.

– For Type 1 organic adhesive,

use a 1/169 U-notch trowel.

– For latex-modified thin-set

mortar, use a 1/89 U-notch

trowel. Roll or trowel adhesive

in parallel rows across the

width or length to avoid trap-

ping air under the membrane.

For installations over non-

porous surfaces, such as

vinyl, laminate and existing

tile—allow adhesive to air-dry,

becoming translucent and

developing tack, before

installing D

urock

tile

membrane. Time will vary

depending on temperature,

humidity and substrate type;

however, a minimum of 15

minutes should be allowed.

3. Install membrane with

cementitious side out. Embed

into adhesive, using the flat

edge of the trowel or with a

non-segmented hand roller.

Start in the center of the