Thermal Transfer Systems M3-VG User Manual

Page 6

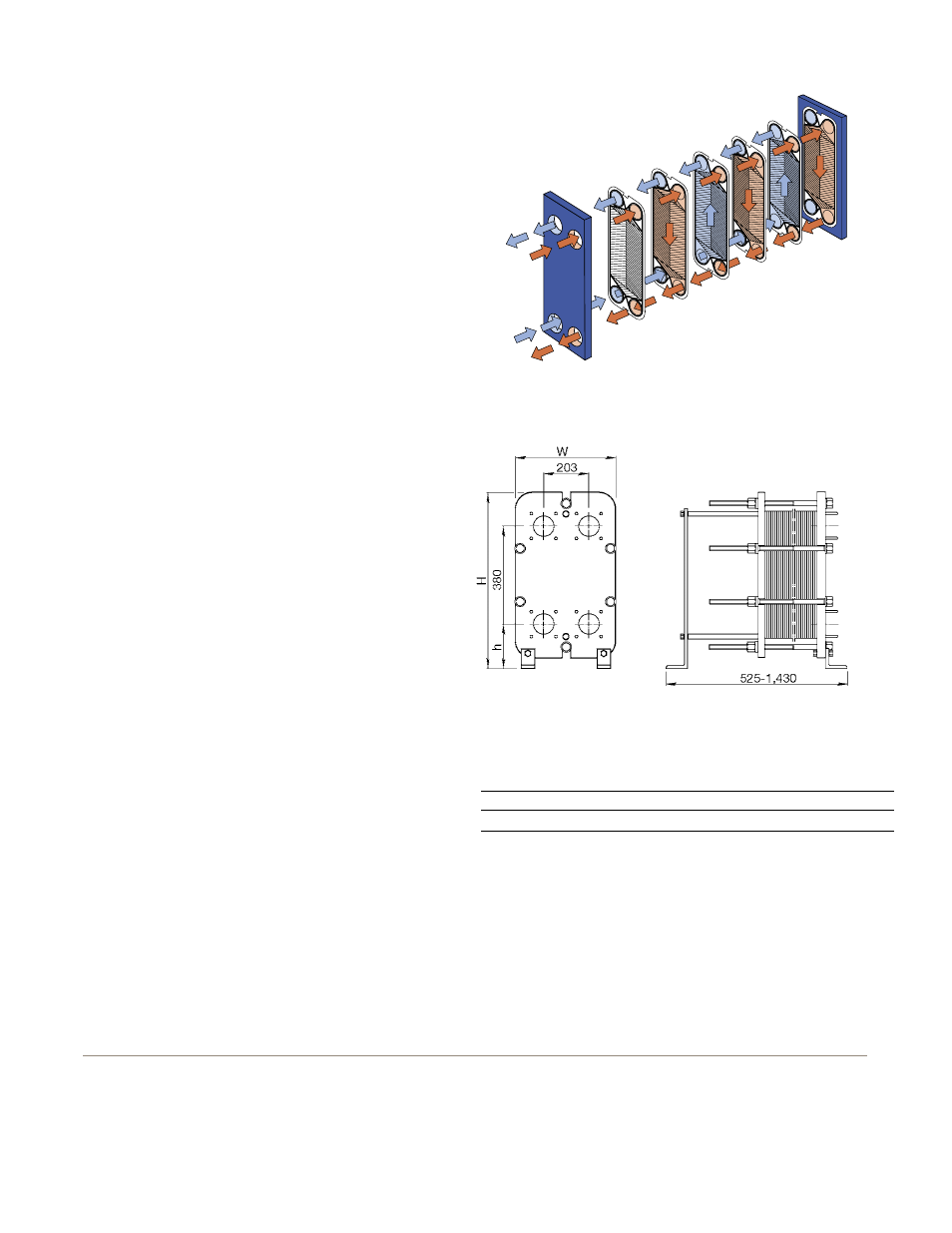

Working principle

Channels are formed between the plates and the corner

ports are arranged so that the two media flow through

alternate channels. The heat is transferred through the plate

between the channels, and complete counter-current flow is

created for highest possible efficiency. The corrugation

of the plates provides the passage between the plates,

supports each plate against the adjacent one and

enhances the turbulence, resulting in efficient heat transfer.

Standard Materials

Frame plate

Mild steel, Epoxy painted

Nozzles

Carbon steel

Lined: Stainless steel, Titanium

Plates

Stainless steel AISI 316 or Titanium

Gaskets

Nitrile, EPDM or HeatSeal F™

Connections

FG ASME

Size 3"

ANSI 150

FD ASME

Size 2 1/2"

ANSI 300

Technical data

Mechanical design pressure (g)/temperature

FG ASME

150 psig /350°F

FD ASME

300 psig /350°F

Maximum heat transfer surface

13 m

2

(140 sq. ft.)

Particulars required for quotation

– Flow rates or heat load

– Temperature program

– Physical properties of liquids in question (if not water)

– Desired working pressure

– Maximum permitted pressure drop

– Available steam pressure

How to contact Alfa Laval

Contact details for all countries

are continually updated on our website.

Please visit www.alfalaval.com to

access the information directly.

PD 68192 E1 0504

All rights reserved for changes in specifications

Flow principle of a plate heat exchanger

Measurements (in/mm)

Type

H

W

h

TS6-FG

27.72/704

15.75/400

7.40/188

TS6-FD

27.72/704

16.14/410

7.40/188

Dimensions

The number of tightening bolts may vary depending on pressure rating.

THERMAL TRANSFER SYSTEMS, INC.

[email protected]

PH: 800-527-0131 FAX: 972-242-7568