Thermal Transfer Systems CA-2000 Series User Manual

Ca -2 000, Fluid cooling | shell & tube ca-2000 series, How to order

C

A

-2

000

262.554.8330

www.thermaltransfer.com

98

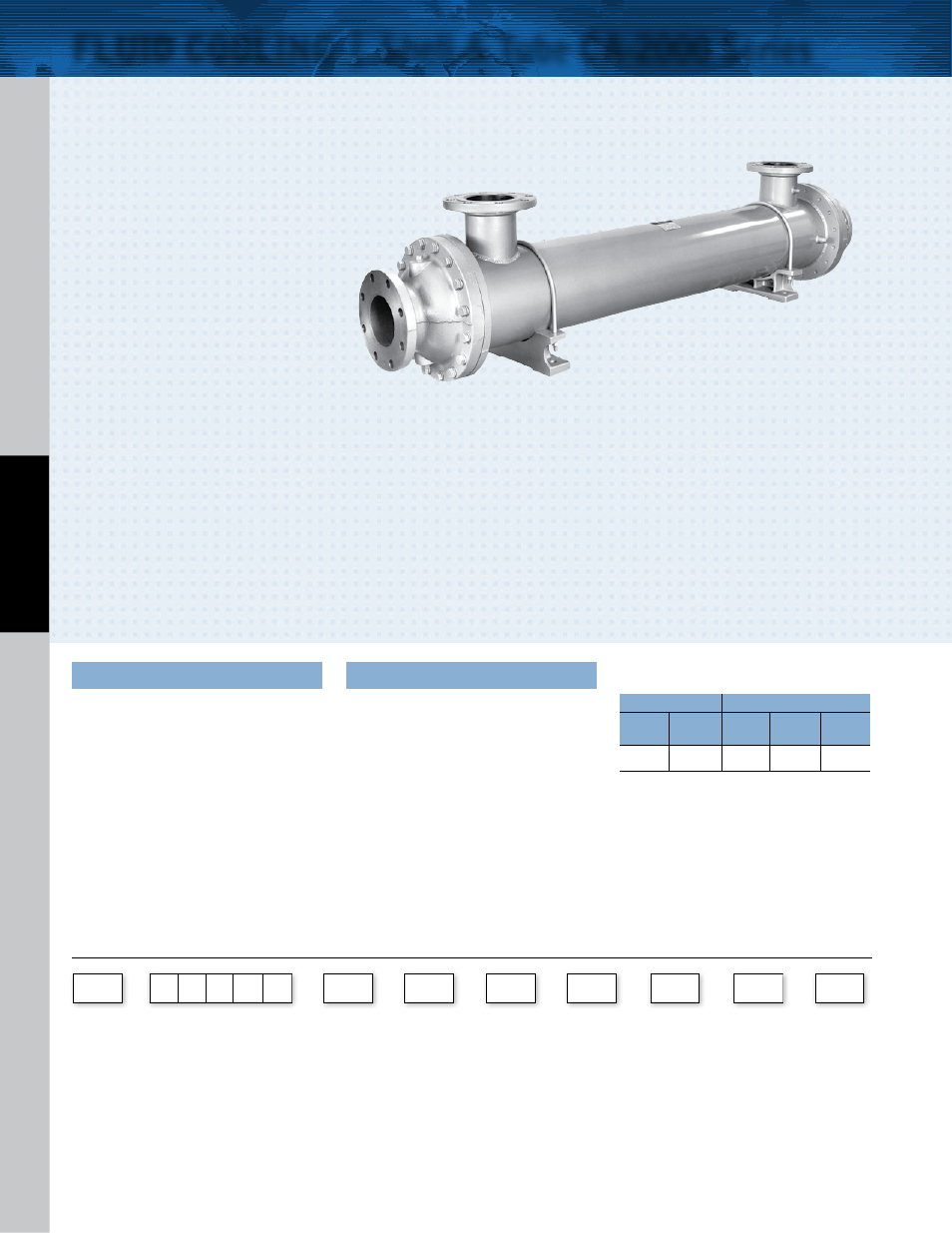

FLUID COOLING | Shell & Tube CA-2000 Series

W

A

T

E

R C

O

O

L

E

D

CA

-2

000

COPPer & STeel COnSTrUCTiOn

Features

n

Super High Flow

n

largest Flow rates &

Heat Transfer Available

n

ASMe Code

n

rugged Steel Construction

n

Custom Designs Available

n

Competitively Priced

n

3/8” & 5/8” Tubes Available

n

Max. 10” Diameter, 12’ long

n

150# AnSi/ASMe Flanged Shell

Connections (Metric Available)

n

Optional Construction on CA-2000

Series: Tubes, Tubesheets, and End

Bonnets

n

End Bonnets Removable For Servicing

n

Saddle Brackets For Incremental

Mounting

n

ASME Code (Section VIII, Division I)

and TEMA-C Construction

Available (Consult Factory for Ordering

Information)

Materials

Headers Steel

Shell Steel

Shell Connections Steel

Baff les Brass

end Bonnets Cast Iron

Mounting Brackets Steel/Cast Iron

Gaskets Nitrile Rubber/Cellulose Fiber

nameplate Aluminum Foil

Ratings

Maximum Shell Pressure 150 psi

Maximum Tube Side Pressure 150 psi

Maximum Temperature 300° F

How to Order

Model Size Selected

Tube

Diameter

Code

6

- 3/8”

10

- 5/8”

Tubeside

Passes

0

- One Pass

T

- Two Pass

F

- Four Pass

–

Baff le

Spacing

Cooling

Tube

Material

Blank

- Copper

Cn

- CuNi

SS

- Stainless

Steel

AD

- Admiralty

Brass

end

Bonnet

Material

Blank

- Cast Iron

nP

- Electroless

Nickel Plate

Tubesheet

Material

Blank

- Cast Iron

W

- CuNi

S

- Stainless

Steel

Zinc

Anodes

Blank

- None

Z

- Zinc

–

–

–

–

–

–

–

Model

Series

CA

CAM

Maximum Flow Rates

Shell Side (GPM)

Tube Side GPM

6”

9”

One

Two

Four

Baff le Baff le

Pass

Pass

Pass

210

320

652

326

163

CA

= NPT tubeside bottom connections; ASME/ANSI flange shell top connections.

CAM

= BSPP shellside connections; BSPP tubeside connections.