Installation, Masonry and factory built fireplace clearances – Regency Hampton HI300 Medium Wood Insert User Manual

Page 8

8

Hampton HI300 Wood Cast Insert

installation

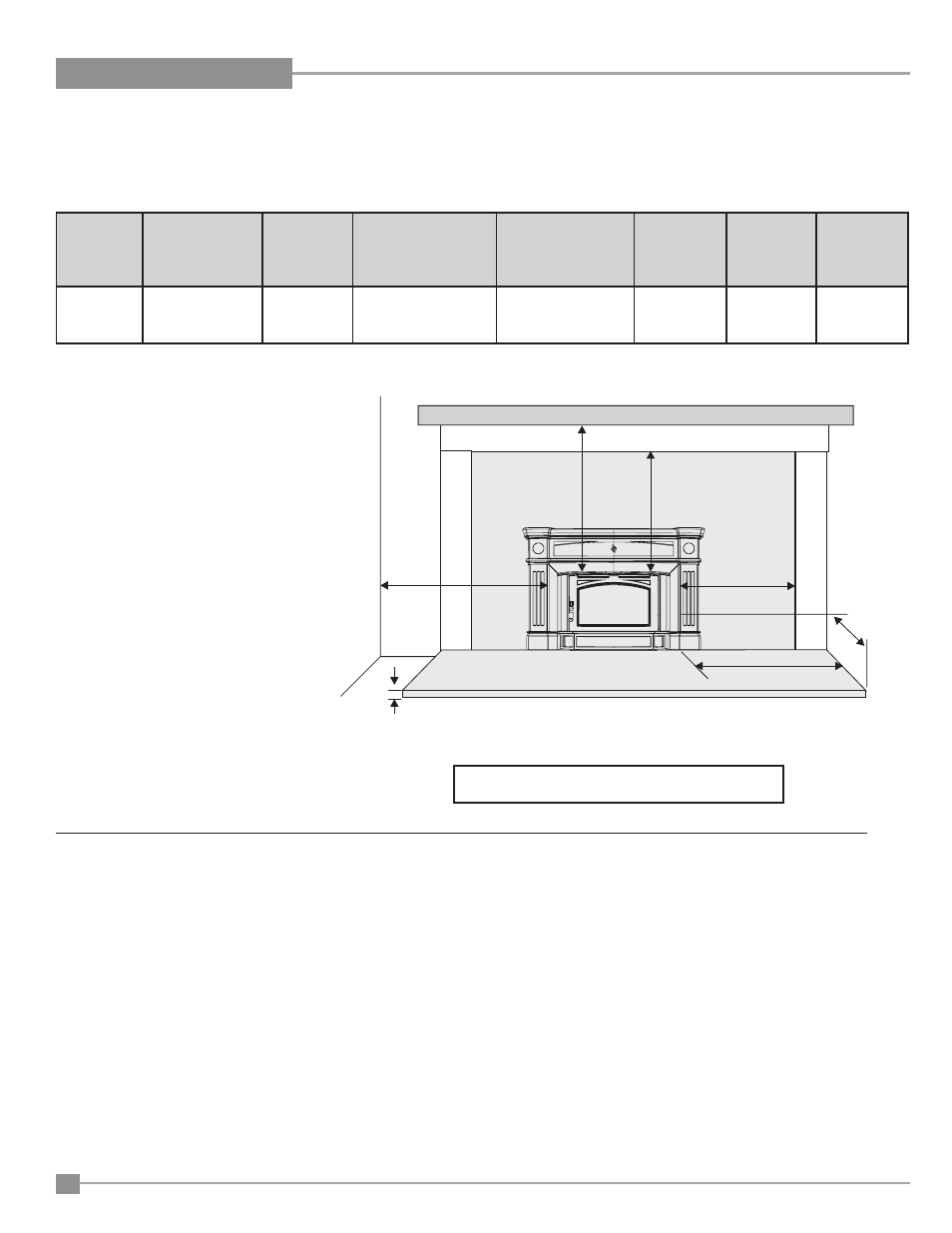

Clearance Diagram for Installations

Side and Top facing is a maximum of 1.5" thick.

Floor protection must be non-combustible, insula-

tive material with an R value of 1.1 or greater.

* Hearth thickness of 0.5" with k value = 0.84",

r value = 0.6 or greater.

Thermal floor protection not required if unit is

raised 3.5" min. measured from bottom of stove. At

this point the standard ember floor protection will

be required. It will need to be a non-combustible

material that covers 16" (406 mm) to the front

of the unit (in Canada 18" (450 mm) and 8" (200

mm) to the sides.

All floor protection must be non-combustible (i.e.,

metals, brick, stone, mineral fiber boards, etc.) Any

organic materials

(i.e. plastics, wood paper prod-

ucts, etc.)

are combustible and must not be used.

The floor protection specified includes some form

of thermal designation such as R-value (thermal

resistance) or k-factor (thermal conductivity).

** a non-combustible mantel may be installed

at a lower height if the framing is made of

metal studs covered with a non-combustible

board.

**

Max. mantle depth is 10" (254mm)

MasonrY and factorY Built fireplace clearances

The minimum required clearances to combustible materials when installed into a masonry or factory built fireplace are listed below.

note: Clearances are the same with standard or oversize cast faceplate.

Minimum Hearth extension for the front (e) and sides

(G) are measured from the fuel door opening.

HoW to deterMine if alternate

floor protection Materials are acceptaBle

The specified floor protector should be 3/8"

(18mm) thick material with a K - factor of

0.84.

The proposed alternative is 4" (100mm) brick

with a C-factor of 1.25 over 1/8" (3mm) mineral

board with a K-factor of 0.29.

step (a):

Use formula above to convert specification

to R-value.

R = 1/k x T = 1/0.84 x .75 = 0.893.

step (b):

Calculate R of proposed system.

4" brick of C = 1.25, therefore

Rbrick = 1/C = 1/1.25 = 0.80

1/8" mineral board of k = 0.29, therefore

Rmin.bd. = 1/0.29 x 0.125 = 0.431

Total R = Rbrick + Rmineral board =

0.8 + 0.431 = 1.231.

step (c):

Compare proposed system R of 1.231 to

specified R of 0.893. Since proposed system

R is greater than required, the system is

acceptable.

definitions

thermal conductance:

C

= Btu

= W

(hr)(ft

2

)(

o

F) (m

2)

)(K)

thermal conductivity:

k = (Btu)(inch) = W = Btu

(hr)(ft

3

)(

o

F) (m)(K) (hr)(ft)(

o

F)

thermal resistance:

R = (ft

2

)(hr)(

o

F) = (m

2

)(K)

Btu

W

A

B

C

D

G

F

E

Unit

adjacent

side Wall

(to side of unit)

a

mantle**

(to top)

b

top

facing

(to top)

c

side

facing

(to side of Unit)

D

minimum

Hearth

extension*

e

minimum

Hearth

thickness*

f

minimum

Hearth

thickness*

G

Wood cast

insert

(Hi300

)

11"/280mm

20"/508mm 12"/305mm Reg. F/P

14"/356mm O/S F/P

8"/200mm Reg. F/P

11"/279mm O/S F/P 18"/455mm

0.5"/13mm

8"/200mm