Installation, Installation into a masonry fireplace, Installation into a factory built fireplace – Regency Hampton HI300 Medium Wood Insert User Manual

Page 10

10

Hampton HI300 Wood Cast Insert

installation

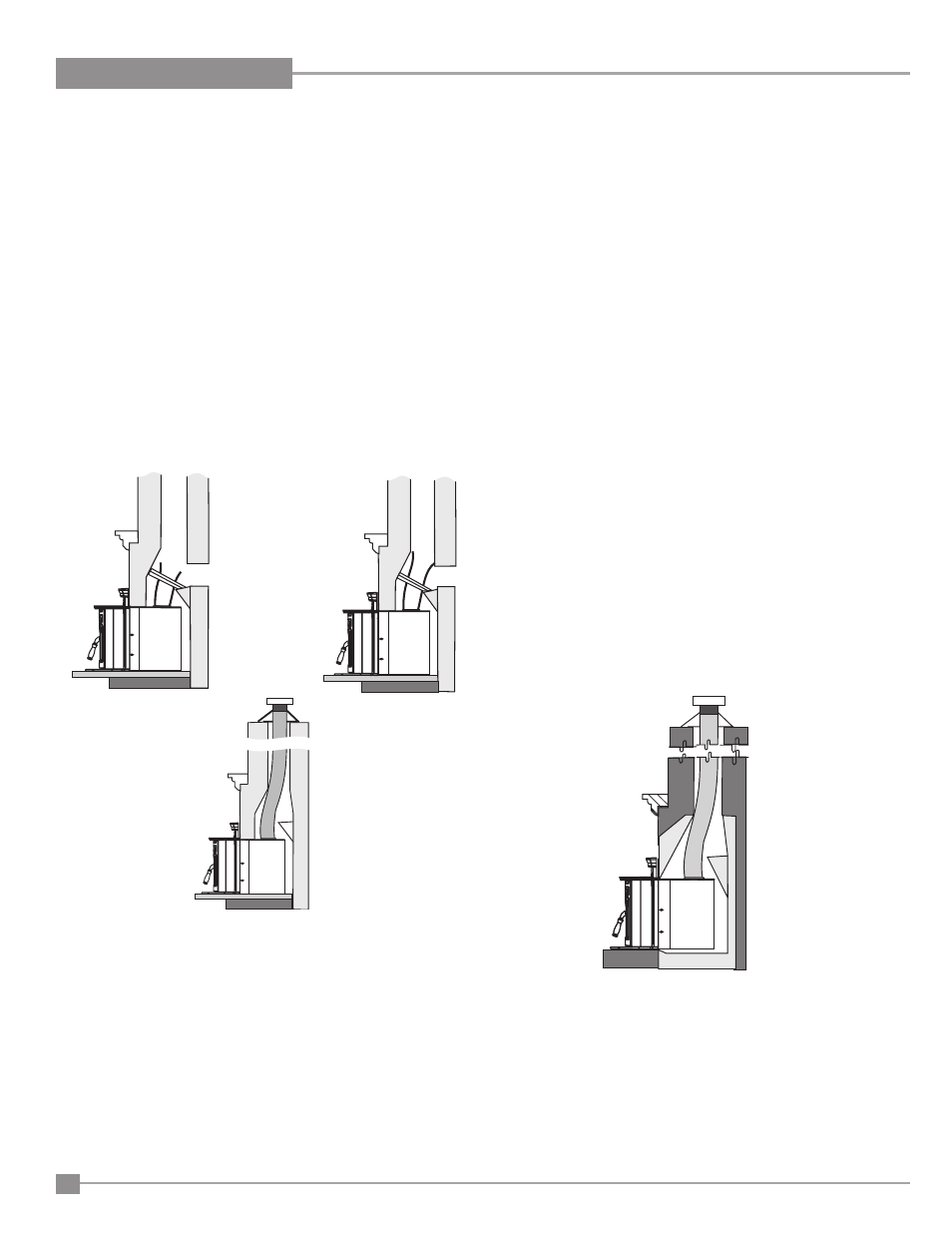

1) Positive Flue

Connection

with Cleanout

2) Direct Flue

Connection

with Cleanout

3a) Full Flue Liner

(No Cleanout Required)

note: a clean-out door is sometimes required, by your inspector,

to be installed when either the positive flue connection or

direct flue connection method is used.

The use of one of the connection methods listed on this page not only

increases the safety of your insert by directing the hot gases up the flue,

but will also help increase the unit's efficiency and decrease creosote

deposits in the chimney.

When a connected flue or liner is in use, the insert is able to “breathe”

better by allowing a greater draft to be created. The greater draft can

decrease problems such as, difficult start-ups, smoking out the door,

and dirty glass.

installation into a

MasonrY fireplace

The insert must be installed as per the requirements of your local in-

spection authority. While a full liner is preferred, three methods of flue

connection are acceptable in most areas in the US, however in Canada

a full flue liner is required.

1) Positive flue connection, where a large blocking plate and a short

connector pipe is used.

2) Direct flue connection, where a smaller blocking plate and a connector

pipe to the first flue liner tile is used.

3) Full flue liner, where a stainless steel rigid or flexible liner pipe is

routed from the insert outlet collar to the top of the chimney.

Hampton highly recommends the use of a full liner as the safest installa-

tion and provides the most optimum performance. Your retailer should

be able to help you decide which system would be the best for your

application.

1) When installed in a factory built fireplace, a full stainless steel rigid

or flexible flue liner is mandatory, for both safety and performance

purposes. When a flue or liner is in use, the insert is able to breathe

better by allowing a greater draft to be created. The greater draft

can decrease problems such as, difficult start-ups, smoking out

the door, and dirty glass.

2) In order to position the flue liner, the existing rain cap must be

removed from your chimney system. In most cases the flue damper

should also be removed to allow passage of the liner.

3) In most cases opening the existing spark screens fully should give

enough room for the insert installation. If it does not, remove and

store.

4) If the floor of your fireplace is below the level of the fireplace open-

ing, adjust the insert's levelling bolts to accommodate the differ-

ence. When additional shimming is required, use non-combustible

masonry or steel shims.

5) Measure approximately the alignment of the flue liner with the

position of the smoke outlet hole on the insert to check for pos-

sible offset. If an offset is required, use a proper stainless steel

unit available with the chimney liner.

6) Once the above items have been checked, slide your insert into

position after first positioning the flue liner and offset if required.

(Re-install raincap at completion of installation).

note: see requirements for installing solid fuel

inserts in factory built fireplaces.

installation into a

factorY Built fireplace