Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 9

d.

Install the oil ring support rail in the lower ring groove

of piston. See picture 21.

e.

Install the oil ring separator in the lower ring groove,

then install one oil ring rail on either side of the

separator.

S&S

®

recommends covering cylinder studs with 3⁄8” i.d. fuel line

to protect piston and rings until cylinder installed.

7.

Install cylinder head alignment dowels in cylinder.

8. Apply very light film of motor oil to piston skirts and cylinder

bores and install rear cylinder. Install rear cylinder head,

referring to following section as necessary.

NOTE - On 4

1

⁄

8

" bore engines, if engine builder chooses to install

front cylinder before installing rear head, rear cylinder should be

temporarily secured with head bolt and washers. If cylinder is not

secured, piston can lift cylinder and disturb base gasket if

flywheels rotated.

9.

Repeat piston installation for front cylinder and

cylinder head.

INSTALL CYLINDER HEADS

NOTE - If different camshaft, or S&S

®

heads assembled by other

source are used, engine builder must confirm lift capability of

valve springs and collars as well as valve-to-valve clearance. Refer

to Installation Information for S&S big twin Camshafts.

Failure to establish correct clearances can cause extensive

engine damage not covered under warranty.

1. Place head gasket on top of cylinder. Locate on dowels

installed in cylinder.

NOTE - If Kevlar

®

reinforced graphite head gaskets are supplied

with engine, they are to be installed dry. If copper head gaskets

are supplied with kit, prepare gaskets with Gasgacinch

®

sealant

before installation. Refer to manufacturer’s instructions for

proper application of sealant, and recommended set-up times.

2. Before installing heads spin each head bolt down on its

respective stud to be sure threads are clean and free of

contamination. Place a drop or two of oil on threads and

under head of each head bolt just prior to final assembly.

NOTE - Light coating of oil on head bolt threads minimizes

friction so torque values will not be distorted. It cannot be

emphasized enough that these steps must be done carefully.

Maintaining a good head gasket seal depends on it.

Improper torquing sequence and head bolt torque values may

cause head gasket failure.

3.

Bolt heads on cylinders. Follow the stock bolt tightening

sequence, and use stock three stage procedure and torque

values shown in Figure 1. See Figure 1.

IMPORTANT NOTE - Proper first time engine start-up and break-

in is critical to achieve permanent and lasting head gasket seal.

Follow “Engine Break-In” procedures at end of section.

Improper first time engine start-up and break-in procedure

may cause head gasket failure.

PUSHROD PREPARATION

1. Disassemble pushrods and pushrod tube covers. Clean

thoroughly and dry with compressed air.

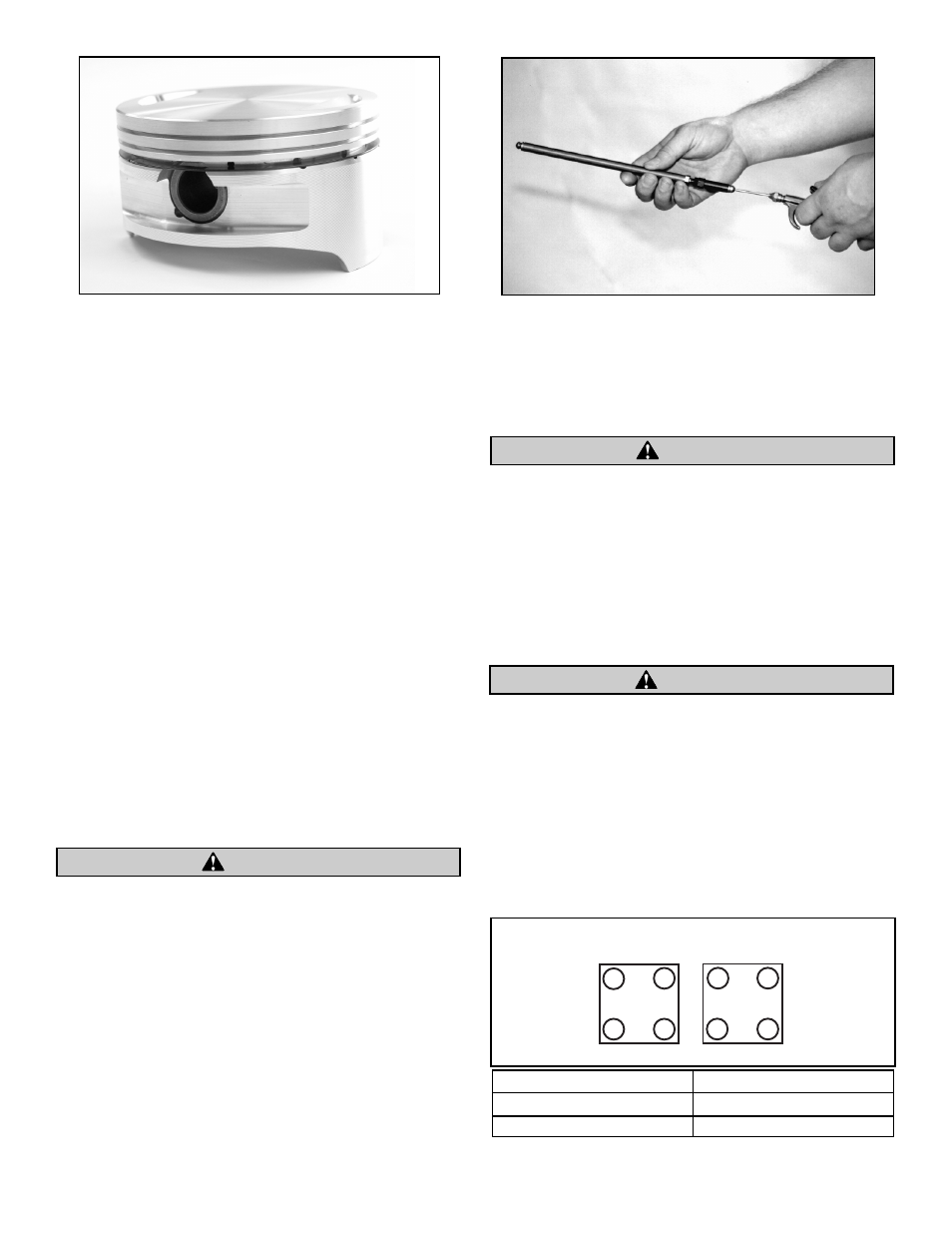

2. Blow compressed air through oil passage in each pushrod to

confirm that passage is clean and free of debris and

obstruction. See Picture 22.

3. Assemble pushrod tube cover assemblies. Lubricate all O-

rings with a light coat of engine oil.

9

Picture 21

Picture 22

CAUTION

CAUTION

CAUTION

1

2

4

3

Rear Head

2

1

3

4

Front Head

Top View

Driveside

Camside

Stage 1

8 Ft.-Lbs.

Stage 2

18 Ft.-Lbs.

Stage 3

Turn additional 90˚

Figure 1