Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 6

NOTE - A dab of Hylomar

®

or other thin gasket sealer in corners

may be used to hold gaskets in place. Otherwise gaskets should

be installed dry.

4.

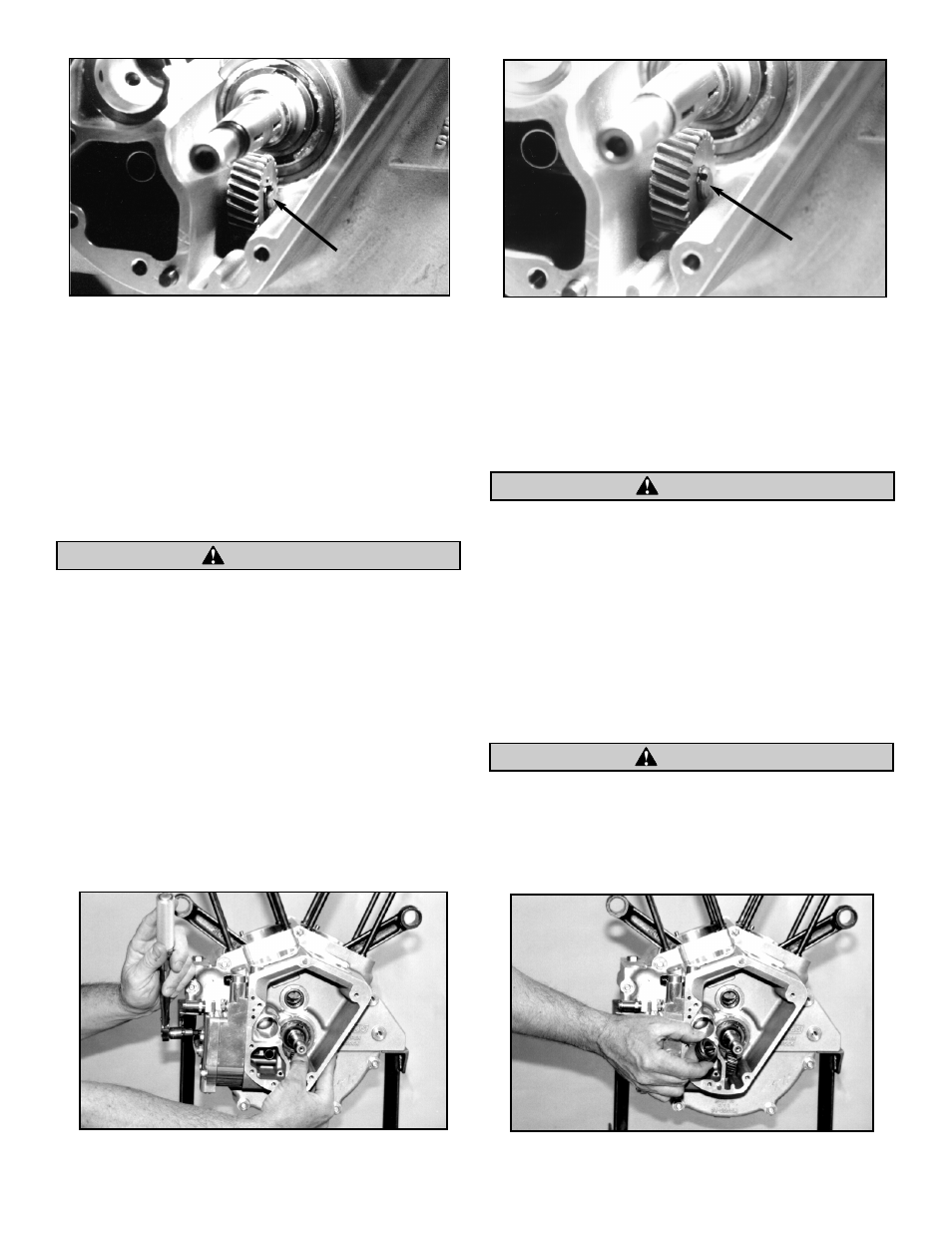

Install driveshaft gear key and snap ring.

NOTE - Be sure drive shaft key and snap ring are installed

properly, paying particular attention to snap ring. If not installed

correctly, “sprung,” or otherwise damaged, snap ring may come

off or allow gear key to come out. See Pictures 11 & 12.

Loss of oil pump drive gear snap ring or key will result in

disengagement of oil pump causing loss of oil pressure and

extensive engine damage.

5. Loosely install two (2) each 1⁄4 -20 x 1-1⁄2” top oil pump bolts,

followed by pump cover and 4 each 1⁄4 -20 x 2-1⁄2” mounting

bolts. Do not tighten at this time.

6. While turning oil pump drive gear to check pump for

binding, gradually tighten 4 - 2-1⁄2” bolts in an X-pattern to

final specifications of 120 in-lbs. See Picture 13. Carefully

tighten short bolts “by feel” with thin box end wrench, or

preferably with a torque adapter, and tighten to 110 in-lbs.

7. Prime pump by removing oil pump check valve ball assembly

and injecting clean motor oil into pump supply fitting while

turning oil pump drive gear. (A large plastic squeeze bottle

works well for priming pump.) Replace check ball, spring,

and cap after oil fills check valve cavity.

INSTALL PINION GEAR, SPACER & NUT

1.

With chamfer on oil pump drive gear facing in towards

shoulder on pinion shaft (See Picture 14), install oil pump

drive gear and key on pinion shaft, followed by drive

gear spacer.

Installing gear backwards can result in a stress riser and cause

shaft to break.

2. Apply red Loctite

®

#272 to pinion gear nut threads. Install

pinion gear, key and nut on pinion shaft and tighten nut to

50 ft-lbs. See Picture 15.

NOTE - Drive gear spacer will not completely fill space between

oil pump drive gear and pinion gear. A gap of up to .125” will

exist and is normal. Engine rotation keeps oil pump gear in place

during normal operation. Spacer prevents gear and key from

becoming disengaged if engine is rotated backwards.

Installing pinion gear or nut without Loctite can cause

damage to shaft, nut, or other parts.

6

Picture 11

Picture 12

Picture 13

Picture 14

CAUTION

CAUTION

CAUTION

Incorrect

correct