Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 18

NOTE - If oil fails to appear at tappet screen port, verify that oil

line routing is correct and that the oil tank is full to the proper

level. Remove the check-ball spring from under the cap of the

shorter tower on the oil pump. Replace cap to avoid losing oil

from pump.

5.

Once oil is seen at the tappet screen port, reassemble all

removed or disconnected components.

6.

Start motorcycle. Verify oil pressure.

NOTE - Oil pressure indicator lamp should light when ignition is

turned on. Lamp will go out after engine is started, and there is

oil pressure at the switch in the crankcase.

7.

Verify that engine oil is returning to oil tank.

Improper first time engine start-up and break-in procedure

may cause head gasket failure.

8.

Initial start up. Run engine approximately one minute at

1250-1750 rpm. DO NOT crack throttle or subject to any

loads during this period as head gaskets are susceptible to

failure at this time. During this time, check to see that oil

pressure is normal, that oil is returning the oil tank, and that

no leaks exist.

9.

Shut off engine and thoroughly check for any leaks or other

problems. Let engine cool to the touch.

10. After engine has cooled, start again and allow the motor to

build some heat. Engine should be run no longer than three

to four minutes. When the cylinders become warm/hot to

the touch (approximately 150º) shut the motor down and let

it cool to room temp. Follow the same cautions as for the

initial start-up, and continue to watch for problems.

11. Repeat this procedure 3 or 4 times. Each successive time it

should take slightly longer to warm up and you can increase

the temp slightly each time (+10º). You can be more liberal

each time with the rpm, gently vary rpm continuously from

idle up to 2500 rpm in the final cycle. Don’t be too concerned

with final carb settings at this time because idle speed and

mixture cannot be correctly set until the engine reaches full

operating temperature. The engine should not reach that

temperature during these cycles. Do not allow engine

temperature to become excessive. After the engine has

cooled to room temperature for the final time you are ready

to start the 1000 mile engine break-in process.

ENGINE TUNING

1.

Carburetor

a.

Refer to Instruction Sheet #51-1012, Installation and

Jetting Instructions for S&S

®

Super E and G Series

“Shorty” Carburetors, for initial set-up and

adjustment of the carburetor.

2.

Ignition Timing

NOTE - S&S recommends using electronic ignition with adjustable

advance curve in 4

1

⁄

8

” bore engines. Adjustable curve permits

slowing rate of advance to control or eliminate pinging under

heavy load or when elevated temperatures or poor quality

gasoline encountered. Install ignition according to

manufacturer’s instructions. Leave spark plugs out while static

timing to ease flywheel rotation. Flywheels in S&S Super

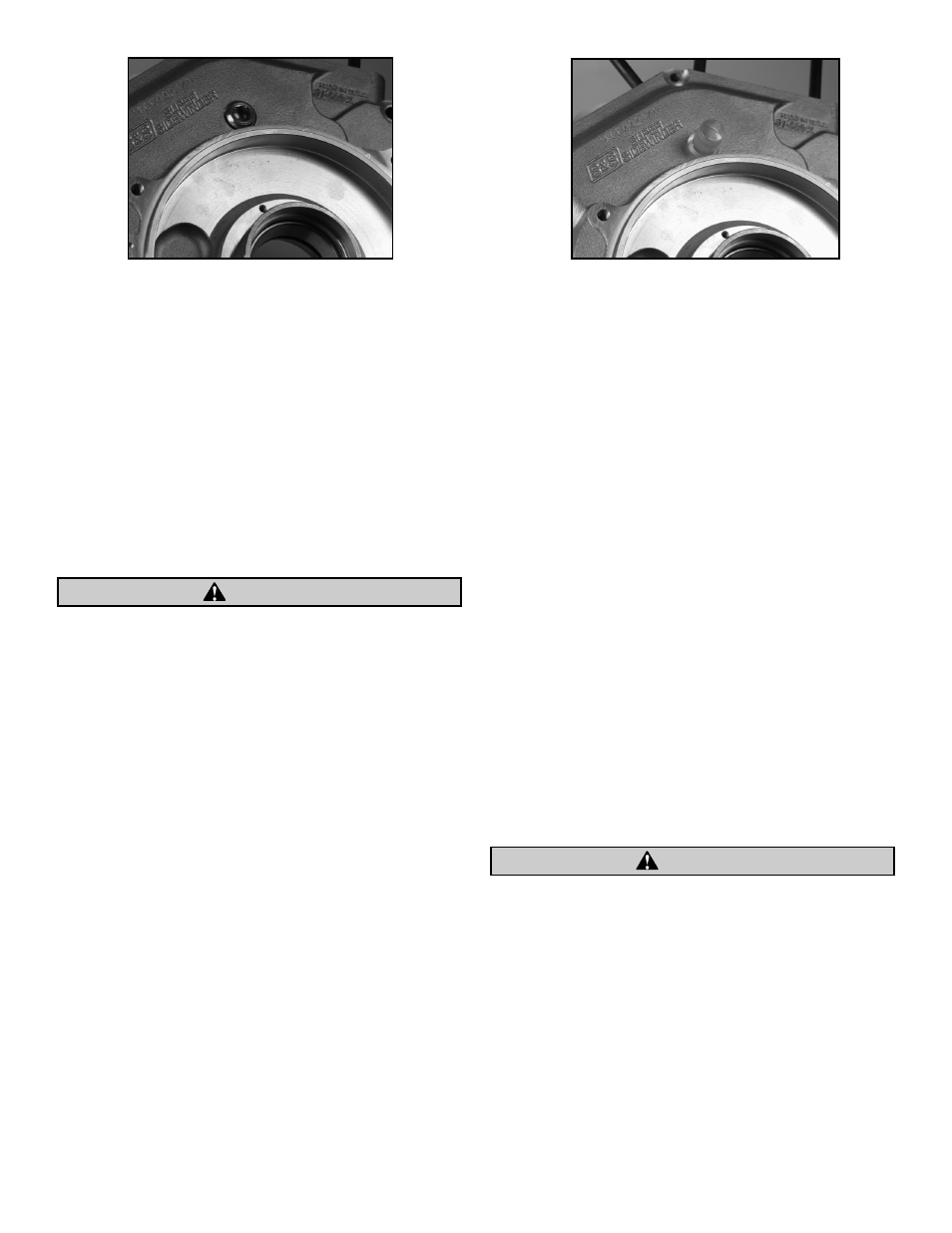

Sidewinder Plus engines have three timing marks:

(F/30) = Front cylinder firing mark, 30° degrees before front

cylinder piston TDC with vertical line in center of hole. See

caution below.

(R/30) = Rear cylinder firing mark, 30° before rear cylinder piston

TDC with dot in center of hole.

(T:F) = Front piston, Top Dead Center with colon (:) in center

of hole.

Most fully electronic ignitions are timed at TDC. Points and other

ignitions with mechanical advance are timed at front cylinder

firing mark. With correct mark centered in timing inspection

hole, ignition at full advance will occur 30° before TDC.

Operating engine with timing too advanced can cause

detonation and damage to engine not covered under warranty.

Additional minor adjustment of timing may be required due

poor quality gasoline, extremely hot climate, etc., but ignition

should occur between 28° and 32° BTDC when fully advanced,

and engine closely monitored for heat build-up. In general,

excessive ignition advance will cause engine to kick back against

the starter during start-up and “buck” when ridden at steady

speed with partial throttle. An advanced condition can also cause

pinging or ignition knock and possible piston damage. These

symptoms may not be noticed if electronic ignition with “soft”

advance curve is used. Excessive ignition retard causes sluggish

performance and severe overheating with possible subsequent

damage to the engine, and must also be avoided. Immediate or

rapid exhaust pipe discoloration is usually a sign of retarded

ignition timing.

18

Picture 40

Picture 41

CAUTION

CAUTION