Warning – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 13

b. Refer to the appropriate service manual for the torque

specifications of the inner primary housing transmission

mounting fasteners.

6. Tighten the four lower engine mounting fasteners to

35 ft-lbs.

7. Install the upper engine mounting bracket. Tighten bracket

to head to 35 ft-lbs. Refer to specific frame make/model year

service manual for torque specification of upper engine

mounting-to-frame fasteners.

8. Refer to the drive section of the appropriate service manual

for reassembly of the primary drive and case. Make certain

to install new chaincase lubricant if applicable.

IGNITION SYSTEM

NOTE - If installing the stock ignition from the removed engine,

refer to the ignition section of the appropriate service manual for

removal and installation.

1.

Install the ignition timing sensor as per manufacturer’s

instruction, using provided ignition cover standoff screws.

Route ignition sensor wire through channel in lower part

of engine gearcase cover and secure with provided

retainer. If applicable, static time ignition as per

manufacturer’s instructions.

2.

If applicable, install and connect the V.O.E.S. (Vacuum

Operated Electric Switch).

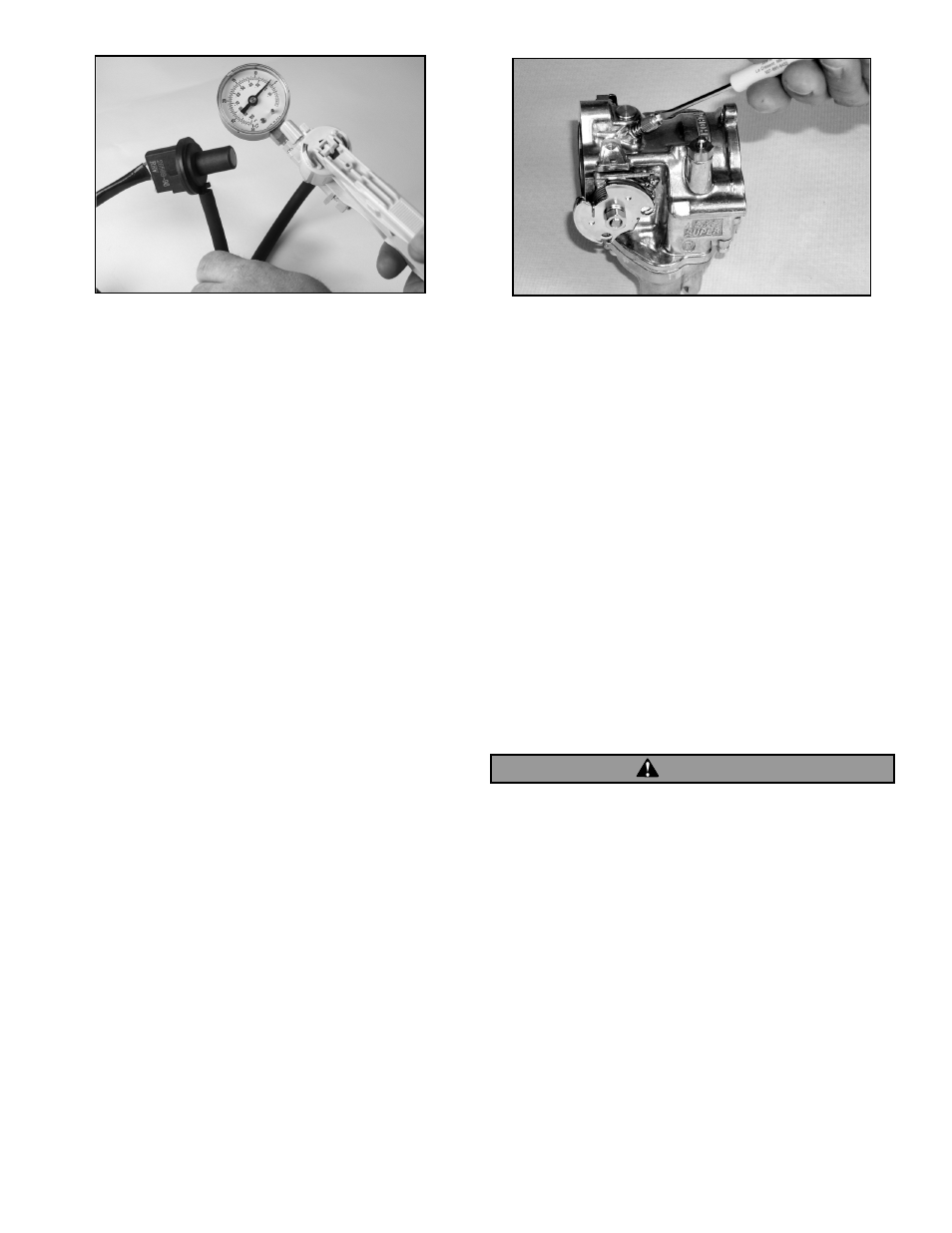

NOTE - V.O.E.S. - S&S

®

Cycle does suggest the ignition system

selected for use with this 4

1

⁄

8

" bore engine utilize the V.O.E.S.

(Vacuum Operated Electric Switch). Check the switch using a

hand vacuum pump with a gauge and set the switch to trip at 6

in. of vacuum-Mercury. See Picture 28.

3.

Install the ignition manufacturer’s recommended spark

plugs.

a.

Refer to ignition manufacturer’s suggested spark plug

gap and check spark plugs. Electronic ignitions generally

require a plug gap of between .038”-.043”.

b.

Apply an anti-seize lubricant to spark plug threads,

install and torque to 11-18 ft-lbs.

4.

Install and connect the ignition coil.

COMPRESSION RELEASES

1.

Refer to included S&S Instruction Sheet #51-1065 or #51-1115

for wiring/cable routing of compression release mechanism,

if applicable.

EXHAUST SYSTEM

1.

Install new woven-metal gasket into exhaust ports of

cylinder heads.

2.

Inspect the exhaust pipe header flanges and retaining rings.

Replace if distorted, warped, or otherwise damaged.

3.

Apply a high-temp. anti-seize lubricant to threads of exhaust

studs at cylinder heads.

4.

Install exhausts to cylinder heads. Hand tighten exhaust

stud nuts.

5.

Attach exhausts to lower mounting bracket. Shim if

necessary. Hand tighten mounting hardware.

6.

Tighten exhaust flange nuts at head to 60-80 in-lbs.

7.

Refer to specifications for the appropriate model and

tighten the remaining mounting hardware to the

recommended torque values.

In some instances, brake master cylinder must be spaced out

from frame to clear crankcase. UNDER NO CIRCUMSTANCES

SHOULD MASTER CYLINDER OR BRAKE LINE BE ALLOWED TO

CONTACT EXHAUST PIPE IN FINAL INSTALLATION. Heat

transferred to brake fluid may expand and cause brakes to

seize, resulting in possible fire hazard and loss of control of

motorcycle with injury or death to rider and others.

NOTE-Make certain that the exhaust system is not pre-loaded, or

in a bind, at the lower mounting points. Make all spacing

adjustments prior to final-tightening of the upper exhaust

mounting hardware at the cylinder heads. Failure to follow this

procedure may cause excessive vibration and result in failure of

exhaust pipes or mounting hardware.

13

Picture 28

Picture 29

WARNING