S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 8

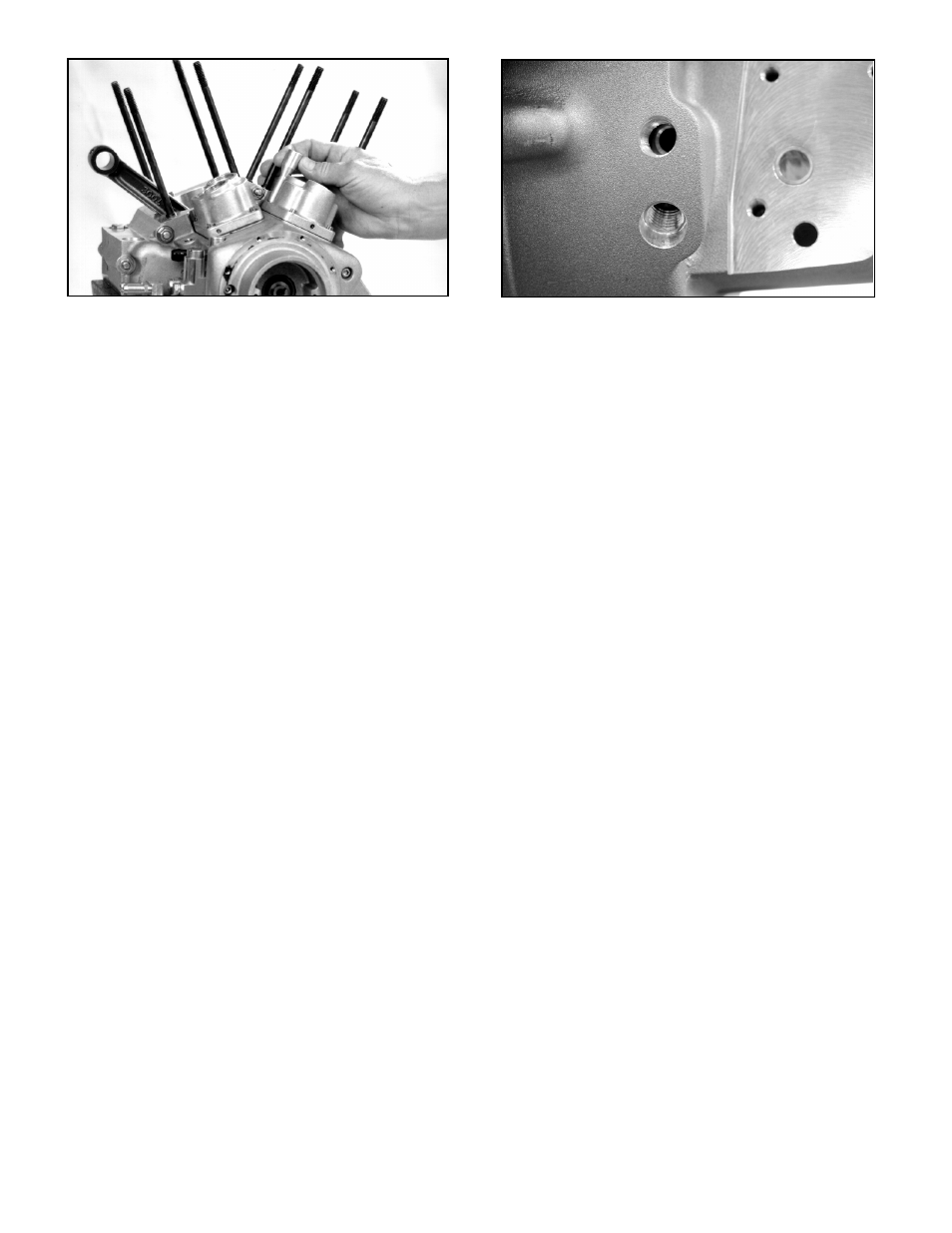

INSTALL LIFTERS AND LIFTER GUIDES

NOTE - S&S® installs HL2T (Hydraulic Lifter Limited Travel) kit in

lifters in assembled and unassembled 4

1

⁄

8

" bore engines.

Install lifters and guides as follows:

1. If installed, remove oil pressure sending unit behind rear

lifter guide opening.

2.

Identify gaskets for front and rear lifter guides. Gaskets are

not interchangeable.

3. Coat lifter guide bores with assembly lube and insert lifters.

Work lifters back and forth in guides, assuring that they

move freely and without binding. Apply engine oil to lifter

rollers and remove any excess.

4.

Thoroughly clean and dry gasket surfaces of lifter guides and

crankcase. Place rear gasket on crankcase, assuring that oil

hole in gasket aligns with passage in case.

5. Taking care not to dislodge or contaminate gasket, lower

rear guide assembly into place. Fingers can be inserted

through front lifter guide opening to support lifters.

6. Insert

Harley-Davidson

®

alignment tool H-D

®

#33443, or

similar tool from other source, in lifter guide screw hole by

oil passage. See Picture 19. Install and tighten guide screws

in three remaining holes to 6 ft-lbs. Remove tool, install

fourth screw, and tighten all four screws to 120 in-lbs.

7.

Repeat procedure for front lifter-guide assembly. Assembly

lube will usually hold lifters in guide during installation. If

resistance encountered during installation, check to see if

lifter has become dislodged.

8. Apply thread sealant to threads of oil pressure switch

and install.

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

INSTALL VENT HARDWARE

1. Install 45° elbow, #31-2022, in vent opening at rear of

crankcase. Steel fittings must be coated with anti-seize

thread sealant or

PTFE plumber's tape before installation

i

n crankcase. See Picture 20.

NOTE - Unused vent hole must be plugged with #51-8330,

1

⁄

4

”-18

NPT pipe plug.

2. Install length of hose on above elbow. Check the orientation

of the one-way check valve. Install the check valve onto

length of hose so that it will allow passage of air out of

engine, but not back in.

NOTE - Proper direction can be checked by blowing through

valve before installation.

INSTALL PISTONS AND CYLINDERS

1. Identify front and rear pistons. The rear piston will have a

notch in the skirt for clearance with the front piston. The

rear piston is to be installed with this notch to the center of

the engine, or towards the front of the motorcycle.

2. Inspect pistons, especially areas around machined surfaces

such as ring grooves and wristpin holes, for burrs. De-burr as

necessary, taking care to remove particles that could become

dislodged inside engine.

3. Measure ring end gaps and adjust as necessary.

a.

Compression ring end-gaps should be between

.017” to .025”.

b.

Oil ring rail end-gaps should be between .015”

to .035”.

4. Thoroughly clean cylinders, pistons, rings, wristpins, and

wristpin retainers in solvent, then hot, soapy water. Take

special care to flush oil passages, and pass clean, white cloth

back and forth through wristpin bores. Dry all with

compressed air and place on clean, dry surface.

5. S&S recommends installing all cylinder base gaskets dry.

Be sure holes in gaskets align with cylinder base dowels

and oil holes.

6. Install rings on pistons.

a.

The moly-faced ring is to be installed in the top piston

ring groove, chamfer-side up.

b.

The plain cast ring is to be installed in the second piston

ring groove, dot up.

c.

Lubricate wristpin, wristpin bushing, and wristpin

bore in piston with assembly lube. Install wristpin

through piston and connecting rod, secure with new

retaining clips.

NOTE - S&S recommends the use of clip installer, part number

H-D

®

#42317, available from Kent-Moore, through Harley-

Davidson

®

, or similar tool, for clip installation.

8

Picture 19

Picture 20