Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 16

NOTE - Air cleaner backplate screws supplied with kit have thread

locking compound on threads. If screw without thread locking

compound is used, a thread locking product such as Loctite

®

243

must be applied, and screws properly tightened.

Failure to apply thread locking compound or properly tighten

screws may cause screws to loosen and fall into engine,

resulting in engine damage not covered

under warranty.

4. Fill gap between backplate mounting ears and

cylinder heads with aluminum spacer and correct

shims. See Picture 5.

5. Bolt backplate to cylinder head with

5

⁄

16

”-18 bolts,

flat washers, and lockwashers.

NOTE - The manifold flange bolts may need to be loosened to

align backplate mounting ears with breather fittings in cylinder

heads. A long,

1

⁄

4

” ball-end Allen socket will aid in accessibility to

the cam-side fasteners of the flanges. Adjust carburetor/air

cleaner assembly as necessary for proper alignment with

mounting holes in cylinder head. Retighten flange bolts evenly to

16 ft. lbs.

c.

Final assembly and checks.

1. Check carb to manifold mounting bolts.

2. Check carb to air cleaner backplate mounting

screws.

3. Check the air cleaner backplate to head

mounting bolts.

4. Check fuel line connections and routing. Avoid

hot surfaces.

5. Check vacuum operated ignition advance

connections if applicable.

6. Check crankcase to backplate vent hose

connections.

7. Check vent hose connection from front cylinder

head to intake manifold.

8. Check fuel overflow hose routing. Avoid hot

surfaces.

9.

Test throttle to be sure it opens and closes freely.

Turn handlebars to extreme left and open and close

throttle, then turn bars to extreme right and check

throttle. When released, throttle should snap

closed in all positions.

10. Install air cleaner element and air cleaner cover

using three

1

⁄

4

-20 x 1” mounting screws provided.

Flat side of pleated filter element #17-0376 goes

against air cleaner backplate. Insure that element

goes around outside edge of locating tang at 9

o’clock position on backplate. Rounded side of

element with S&S

®

Part # goes toward outside.

Correctly installed element will remain in place on

backplate without support.

OIL LINE INSTALLATION

1.

Refer to service manual. Remove and wash oil tank

thoroughly. Clean or replace oil lines. Reinstall oil tank.

2.

Install and connect oil filter mounting bracket to the front of

engine crankcases, if applicable. Refer to service manual for

oil hose routing and specifications. Install new oil filter.

Improper installation of oil lines or fittings may result in parts

damage not covered under warranty.

16

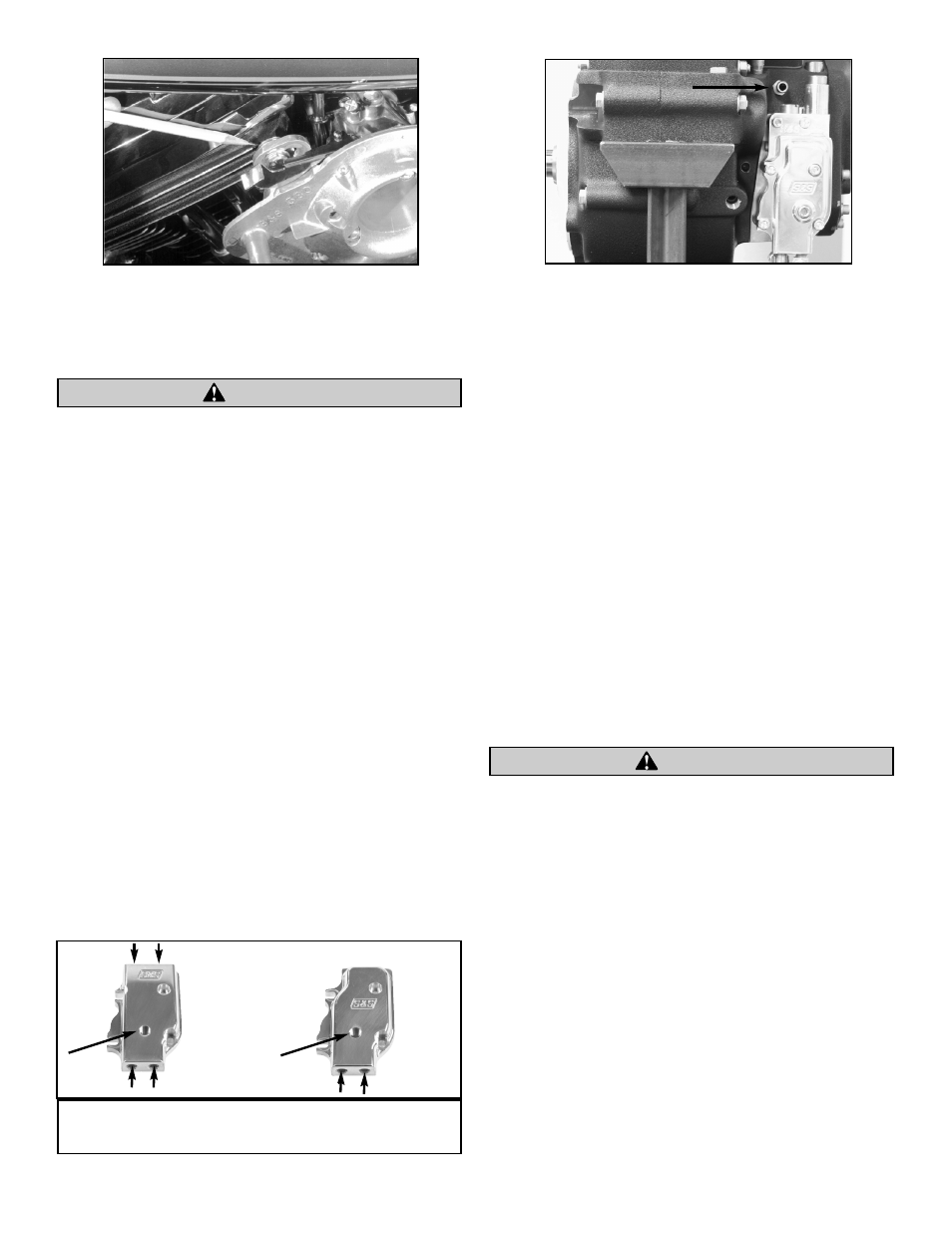

Picture 35

Picture 36

CAUTION

Picture 37

1- Top Oil Return Hole

3- Lower Oil Return Hole

2- Top Oil Supply Hole

4- Lower Oil Supply Hole

5- Middle Oil Supply Hole

1

2

5

3

4

4

3

5

CAUTION