Caution warning caution, Warning caution warning – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 12

S&S

®

recommends that the primary drive and housing be

removed when installing this engine in order to ensure all

components are in proper alignment.

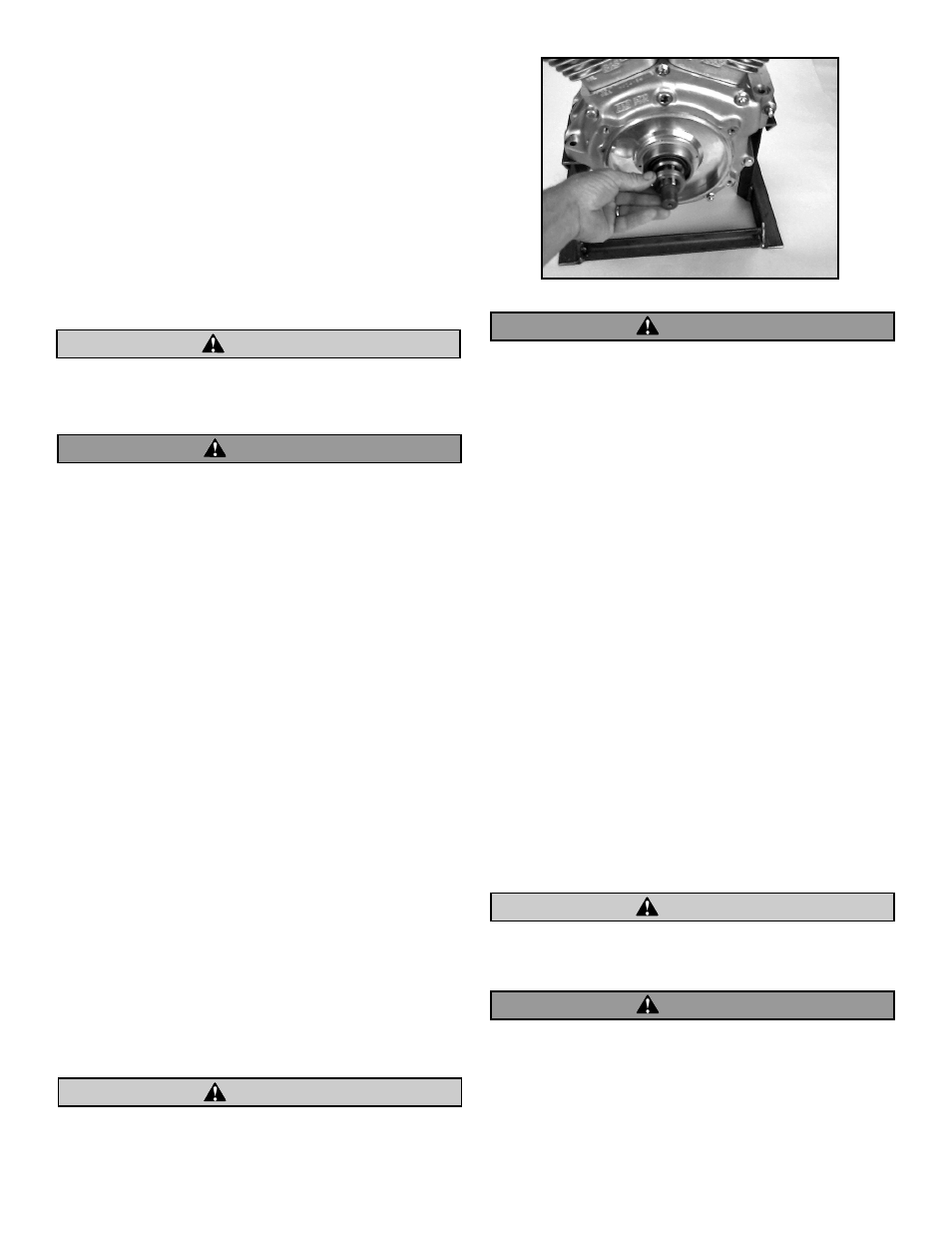

NOTE - Install the charging system to the crankcase as per the

appropriate service manual according to the specifications for the

particular model. Use new stator fasteners if applicable. If

necessary, install spacer for 45 amp alternator. This step is not

required for all models. After installation of flywheel assembly,

S&S

®

drive sprocket spacer #31-4011 and Timken

®

main bearing

seal, place S&S spacer #31-4033 (not provided) on sprocket shaft

between spacer #31-4011and alternator rotor. See Picture 27.

Dimensions of spacer #31-4033 are 1.130” (I.D.) x 1.730” (O.D.) x

.325” (thickness).

Failure to use spacer #31-4033 with 45 amp alternator will

cause rotor to bottom against crankcase when sprocket nut is

tightened, causing damage to crankcase, rotor, or both.

To insure safe operation of motorcycle, these operations must

be performed correctly and in a professional manner.

SOLID-MOUNT CHASSIS

1.

Refer to the drive section of the appropriate service manual

and loosen the transmission to frame mounting hardware.

2.

Place the engine on the mounting pads of the frame. Install

and tighten the two rear mounting bolts. Check the

relationship of the front engine mount to frame.

NOTE - With the rear crankcase fasteners tightened, there

should not be any space between the engine mounting pad and

the front crankcase mount. Due to variations with different

frames a gap may exist here. If this situation is found, use the

appropriate thickness of shims to eliminate this gap. Failure to

correct this may cause the crankcases to be in a “bind” when the

front engine mounting fasteners are tightened, resulting in an

engine vibration.

3.

Install the two front engine mounting bolts.

NOTE - The front two engine mounting fasteners should install

easily through the frame and crankcase. If it requires that these

bolts be “driven” through the mounting holes, the crankcases

may again be in a “bind”, resulting in an engine vibration.

4.

Loosen all four lower mounting fasteners.

5. Refer to the drive section of the appropriate service manual.

Install the inner primary chaincase to the transmission and

engine crankcase. Make certain to use a new engine-to-

primary O-ring and lock tabs or safety wire on the inner

chaincase fasteners.

Failure to use new lock tabs or safety wire on inner primary

chaincase mounting hardware may result in the fasteners

backing out and possible damage to the primary drive.

Loose fasteners inside of primary chaincase may cause the

transmission to “lock up”, resulting in possible loss of control

of motorcycle with injury or death to riders and others.

6.

Refer to the drive section of the appropriate service manual.

Tighten the transmission to the frame.

7.

Tighten the four lower crankcase fasteners to 35 ft-lbs.

8.

Install the upper engine mounting bracket. Pay particular

attention to alignment with frame. Shim as needed. Tighten

bracket to head to 35 ft-lbs. Refer to specific frame

make/model year service manual for torque specification of

upper bracket-to-frame fastener.

9. Refer to the drive section of the appropriate service manual

for reassembly of the primary drive and case. Make certain

to install new chaincase lubricant if applicable.

RUBBER-MOUNT CHASSIS

1.

Lift and support the transmission case to bring the rear

engine mount pad relatively level with the bottom

frame tubes.

2.

Place engine in position on rear engine mounting pad.

3.

Install and hand tighten rear engine mounting fasteners.

Install front mount with stabilizer, if applicable, and

hand tighten.

4.

Refer to the drive section of the appropriate service manual.

Install the inner primary chaincase to the transmission and

engine crankcase. Make certain to use a new engine- to-

primary O-ring and lock tabs or safety wire on the inner

chaincase fasteners.

Failure to use new lock tabs or safety wire on inner primary

chaincase mounting hardware may result in the fasteners

backing out and possible damage to the primary drive.

Loose fasteners inside of primary chaincase may cause the

transmission to “lock up”, resulting in possible loss of control

of motorcycle with injury or death to riders and others.

5. Tighten primary housing to engine crankcase and

transmission case.

a. Torque inner primary housing engine mounting

fasteners to 22 ft-lbs.

12

CAUTION

WARNING

CAUTION

Picture 27

WARNING

CAUTION

WARNING