Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 3

Failure to observe the previous instructions may result in

engine damage not covered under warranty.

FLYWHEELS

Confirm pinion shaft main bearing fit. Correct size bearing is

supplied with engine, but must be verified by engine builder.

Flywheel assembly can then be prepared for installation.

NOTES

●

Refer to information tag on crankcases for final honed size

of pinion shaft main bearing race.

●

S&S

®

pinion shaft main bearing fitting charts #1 and #2 use

Harley-Davidson

®

bearing color codes.

●

All measurements must be taken with parts at room

temperature, approximately 70° F.

1.

Fitment Method A - Use Chart 1.

a. Refer to information tag on crankcases to determine

final honed size of inside diameter of pinion shaft main

bearing race.

b. Measure pinion shaft bearing surface diameter.

c.

Cross reference pinion race inside diameter with pinion

shaft bearing surface outside diameter to determine

correct color code.

EXAMPLE - Pinion shaft bearing surface diameter measures

1.2499” and is between 1.2498” and 1.2500” in left “Pinion Shaft

Bearing Diameter” column. Pinion bearing race inside diameter

is 1.7510” and falls between 1.7509” and 1.7511” in middle

“Bearing Race Diameter” column. Correct bearing color code

where two columns intersect is “BLUE”. Selecting color where

columns intersect provides proper fit for normal service. If looser

fit is desired, select bearing color directly to right of color

indicated from selection process. If color indicated from selection

process is located in right color column, go to next row directly

below and select color in left color column.

2.

Fitment Method B - Use Chart 2.

a. Refer to information tag on crankcases to determine

final honed size of inside diameter of pinion shaft main

bearing race.

b. Measure pinion shaft bearing surface diameter.

c. Subtract pinion shaft bearing surface diameter from

pinion bearing race inside diameter.

d. Select range in left “Bearing Race Diameter minus

Pinion Shaft Bearing Diameter” column where

difference best splits high and low parameters of range.

Corresponding color bearing set in right “Bearing Color

Code” column provides proper fit for regular service.

EXAMPLE - Pinion bearing race inside diameter is 1.7510”. Pinion

shaft bearing surface diameter is 1.2499”. 1.7510” minus 1.2499”

is .5011”. Difference of .5011” splits .5009” to .5013” range in

third row exactly. Corresponding “BLUE” color code in right

column should be used. Notice that .5011” fits in several range

groups. Try to select group where difference falls closest to

middle of range. If you are not sure, select color that corresponds

with group closer to top of chart. This will provide slightly looser

bearing fit and help prevent bearing seizure. Selecting next color

up on chart may also be done if looser fit is desired for

competition applications.

CRANKCASES

NOTE - S&S crankcases are sold in matched sets only. Individual

case halves are not available.

1. Disassemble crankcases & wash in hot, soapy water. Rinse

case halves and blow dry with compressed air. Check all

internal passages. Coat bearing surfaces with a light oil to

prevent rust.

2.

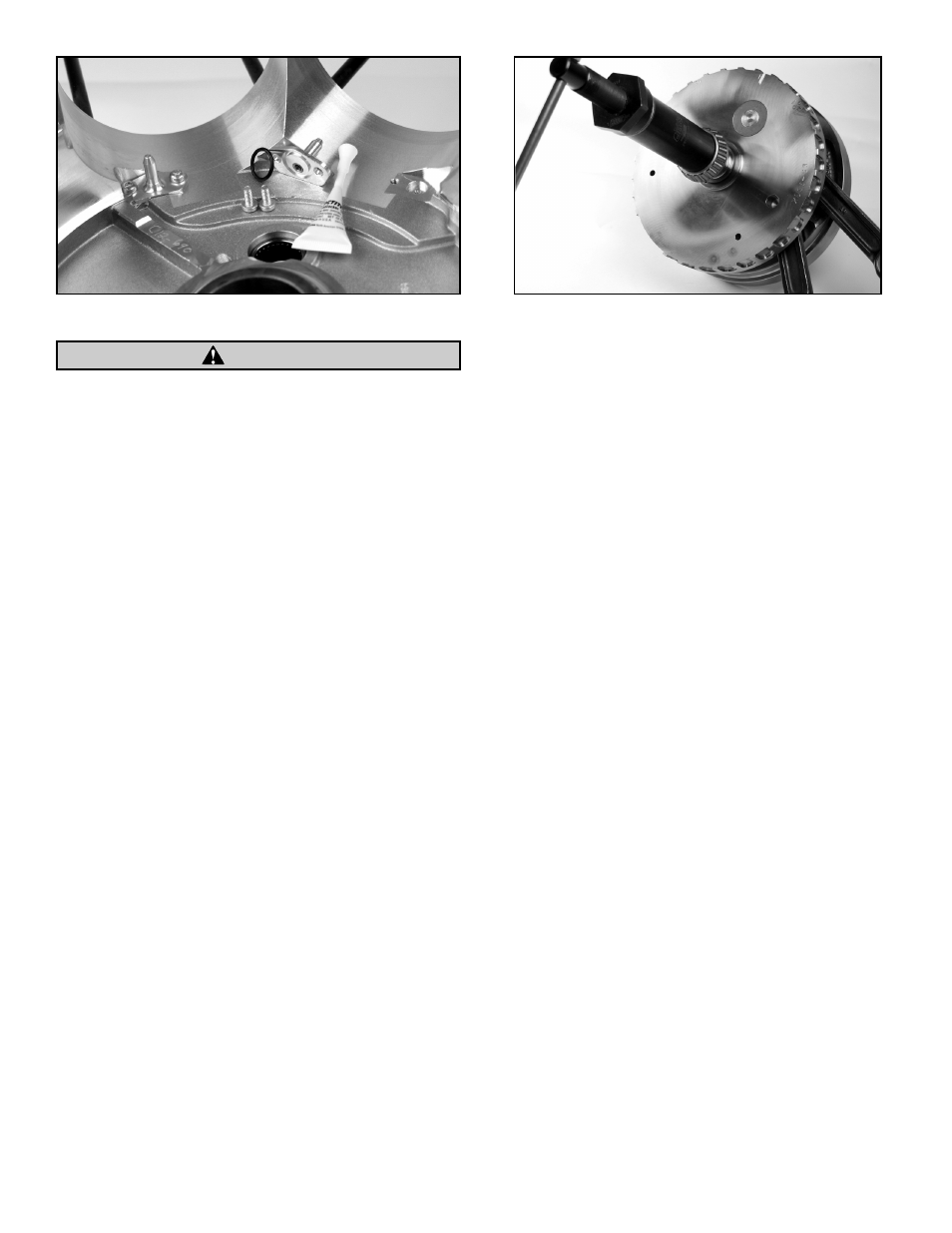

Install piston oilers - right-side crankcase.

a.

Lubricate O-ring with engine oil and install in

piston oiler.

b.

Apply Loctite

®

243 to screws. Install oilers, tighten screws

to 25 in-lbs. See Picture 1.

INSTALL FLYWHEELS IN CRANKCASE

1.

Thoroughly clean parts according to instructions previously

mentioned. Apply coat of assembly lube to bearing surface

of sprocket shaft and inner race of Timken

®

bearing. Install

bearing on shaft with appropriate tool. See Picture 2.

NOTE - S&S does not recommend using a press to install sprocket

shaft bearings, as this can push flywheels out of true. Correct

bearing installation tools are available from Harley-Davidson

®

and other sources.

3

Picture 1

Picture 2

CAUTION