Caution – S&S Cycle Bore 4 1⁄8 V-Series Engines User Manual

Page 5

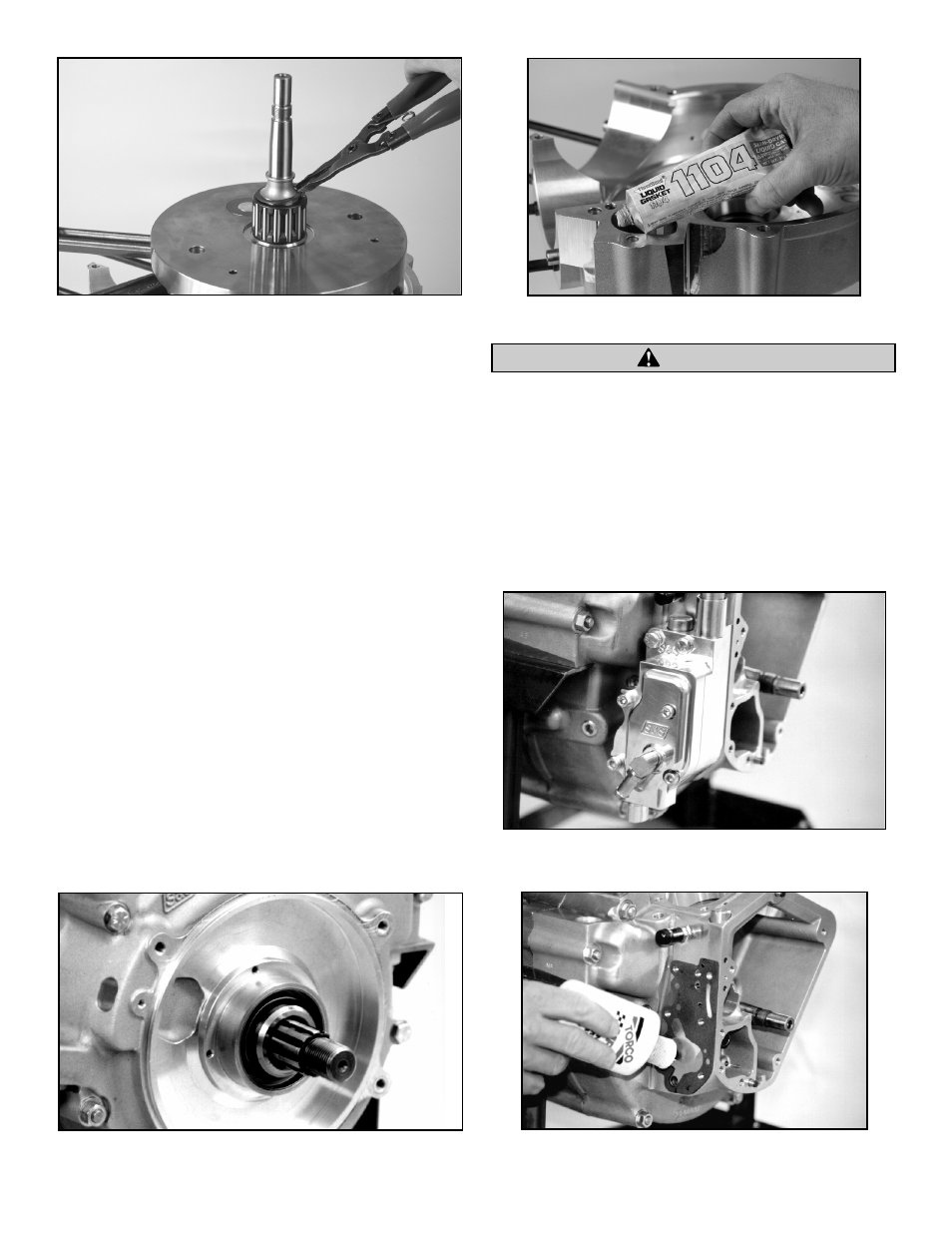

NOTE - Because of sealed, wet primary in Harley-Davidson

®

Evolution

®

models drive trains, S&S

®

installs sprocket shaft seals

with spring facing out. See Picture 8.

5. Allow crankcase sealant to cure per mfr.’s instructions, then

pour four ounces of motor oil over bearing end of

connecting rod assembly and into flywheel cavity. Rotate

flywheels several times to distribute oil over connecting rod

bearings. Assembly should turn freely and without binding.

INSTALL OIL PUMP

1.

Disassemble, clean and inspect oil pump, leaving supply drive

gear, key, and snap ring in place on shaft.

2. Reassemble pump, applying assembly lube to gears and

gear cavities in pump body. Remove excess to avoid

contaminating gaskets. Rotate gears as preliminary

check for bind, and to confirm that drive gear keys are

properly installed.

NOTE - If bind occurs, determine whether problem is with supply

or return gears by removing idler gear from either side and

rotating pump. When binding gear is removed, pump will rotate

freely. Problem can usually be corrected by rotating gear 180°.

NOTE - S&S HVHP oil pumps offer more than one location for oil

supply fitting. Lowest fitting should not be used on models with

oil tank below transmission. S&S recommends stock placement

for oil supply fitting in Dyna™ and late FL models. See Picture 9.

Routing oil supply line to lowest fitting on models with oil

tank below transmission could allow air to enter oil pump

under certain circumstances, causing “air lock”, loss of

lubrication and engine damage.

3. Apply assembly lube to oil pump driveshaft and driveshaft

bushing in crankcase. See Picture 10. Install oil pump in

normal fashion, placing pump drive gear #33-4230 over

driveshaft as shaft is passed through crankcase bushing.

5

Picture 6

Picture 7

Picture 8

Picture 10

Picture 9

CAUTION