Danger – MacDon R80 Rotary Disc User Manual

Page 27

OPERATION

Form # 169089

25

Model Year - 2009

CROP

X

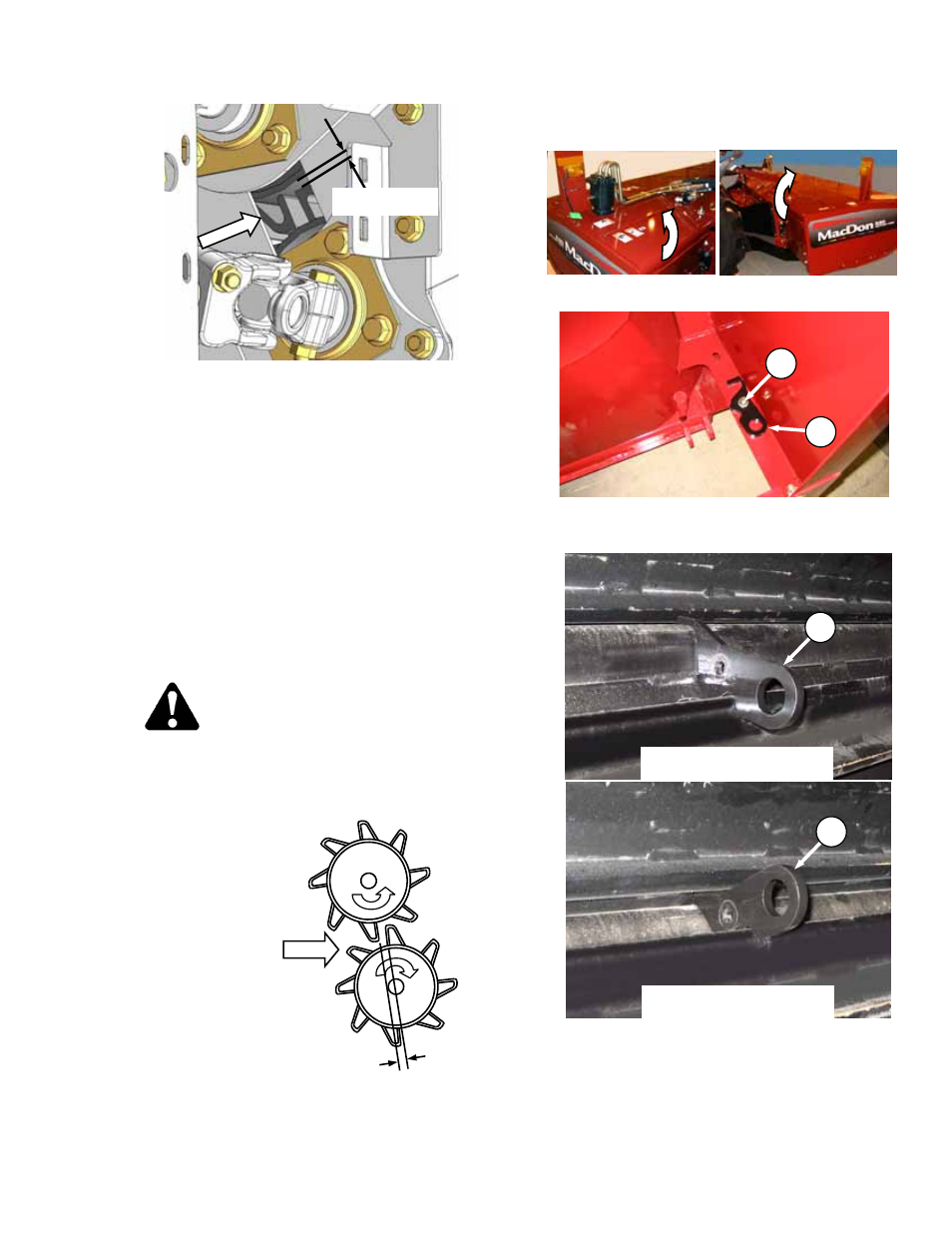

f. Inspect roll gap at both ends of the rolls at

access port.

IMPORTANT

Roll timing is critical when the roll gap is

decreased because:

• Conditioning is affected, and

• The bars may contact each other.

Refer to Section 6.12.5.2, Roll Timing.

6.12.5.2 Roll Timing

For proper conditioning, the rolls must be

properly timed with each steel bar on one roll

centered between two bars of the other roll as

shown. The factory setting should be suitable

for most crop conditions.

DANGER

Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could engage

an idling machine.

Check roll timing

(distance ‘X’) at

each end of the

rolls with the

header fully

lowered using the

gauge located

inside the RH end

panel of header.

a. Lower header to ground, shut down tractor and

remove key.

b. Open both rear drive shields.

c. Remove bolt (A) and nut, and remove gauge (B)

from inside panel at RH end of header.

d. From the rear of the header, locate gauge (B) at

centre of rolls as shown and manually turn rolls

to limits of gauge. Rolls will engage the gauge if

timing is correct.

(continued next page)

A

B

B

START POSITION

GAUGE POSITION

B

ROLL GAP