Danger – MacDon R80 Rotary Disc User Manual

Page 24

OPERATION

Form # 169089

22

Model Year - 2009

6.12 HEADER OPERATION

Satisfactory operation of the header in all

situations requires making proper adjustments to

suit various crops and conditions.

Correct operation reduces crop loss and

increases productivity. As well, proper

adjustments and timely maintenance will

increase the length of service you receive from

the machine.

The variables listed below and detailed on the

following pages will affect the performance of

the header. You will quickly become adept at

adjusting the machine to give you the desired

results.

VARIABLE SECTION

Disc Speed

6.12.1

Cutting Height

6.12.2

Header Angle

6.12.3

Header Flotation

6.12.4

Roll Gap/Timing/Alignment

6.12.5

Roll Tension

6.12.6

Forming Shields

6.12.7

Ground Speed

6.12.8

Windrow Forming Rods – Grass Seed 6.12.9

Converging Drums – Grass Seed

6.12.10

Double Windrowing

6.12.11

6.12.1 Disc

Speed

The disc header can be used to cut a variety of

crops and for the best cutting results, a range of

disc speeds is recommended for each type of

crop and condition. See table below.

CROP CONDITION

DISC

RPM

Heavy 2300-2500

Alfalfa

Light 1600-2000

Sudan, Sorghum,

Haygrazer, Timothy

Tall & Stemmy

2300-2500

Dense 2500

Short Grass

Thin 1800-2000

Disc speeds are set and adjusted from the cab

using without shutting down the windrower.

Refer to M150/M200 Self-Propelled Windrower

Operator’s Manual.

6.12.2 Cutting

Height

Cutting height is determined by the angle of the

cutterbar/header which can be adjusted with the

center link, either hydraulically or mechanically.

Optional adjustable gauge rollers or skid shoes

are available for 16 ft headers to also provide

different cutting heights. Refer to following

paragraphs.

Cutting height should be adjusted for optimum

cutting performance without allowing excessive

build-up of mud and soil inside the header which

can lead to poor crop flow and increased wear

on cutting components.

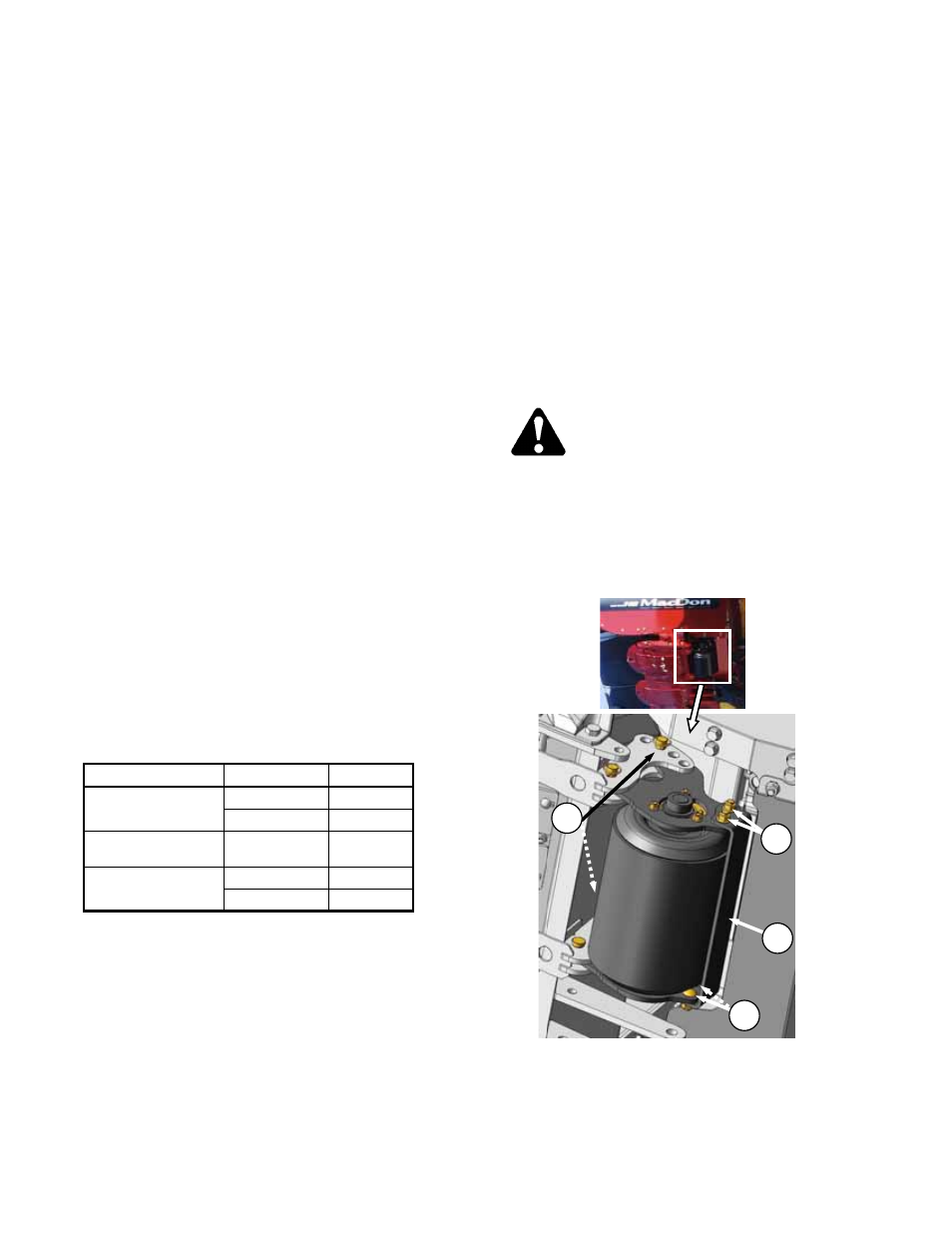

6.12.2.1 Gauge Roller Height Adjustment

DANGER

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine; stop engine, remove key and

engage header lift cylinder stops before

going under machine for any reason.

a. Raise header fully, stop engine, and remove

key. Engage header lift cylinder stops.

b. Remove lynch pin and remove adjuster pin (A)

from one side of roller.

(continued next page)

A

B

C

C