Maintenance, Reassembly, Installing pans onto finisher blades – Multiquip JTNSW20HTCSL User Manual

Page 35

JTNS20H/SW20H-SeRIeS RIDe-ON pOWeR TROWeL • OpeRaTION maNuaL — Rev. #4 (10/15/13) — page 35

maintenance

in Figure 39. A thin shim may be required to cover the

blade holes on the trowel arm. Make sure to align the

trowel adjustment bolt with the fixture adjustment bolt.

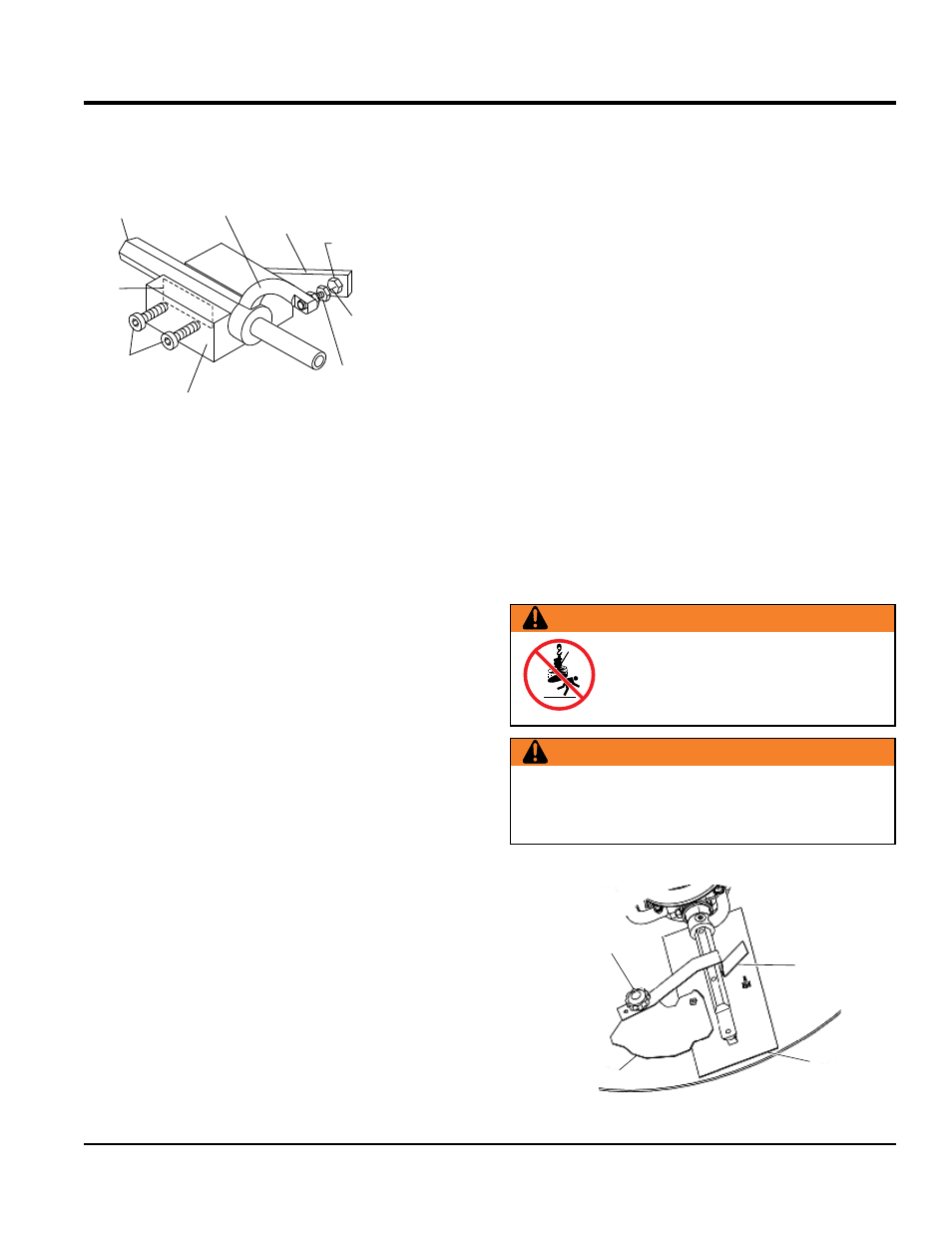

Figure 39. Trowel Arm Adjustment Fixture

Components

5. Use an allen wrench to tighten the locking bolts

securing the trowel arm in place.

6. Adjust the bolt "distance" shown in Figure 39 to match

one of the arms. The other arms will be adjusted to

match this distance.

7. Loosen the locking nut on the trowel arm lever, then

turn the trowel arm adjusting bolt until it barely touches

(.010") the fixture adjusting bolt.

8. Once the correct adjustment is made, tighten the lock

nut on the trowel arm to lock in place.

9. Loosen locking nuts on the adjustment fixture, and

remove trowel arm.

10. Repeat steps for the remaining trowel arms

reassembly

1. Clean and examine the upper/lower wear plates and

thrust collar. Examine the entire spider assembly. Wire

brush any concrete or rust build-up. If any of the spider

components are found to be damaged or out of round,

replace them.

2. Make sure that the bronze trowel arm bushing is not

damage or out of round. Clean the bushing if necessary.

If the bronze bushing is damaged or worn, replace it.

3. Reinstall bronze bushing onto trowel arm.

4. Repeat steps 2 -3 for each trowel arm.

Arm

Trowel Arm

Lever

Fixture

Arm

Adjustment

Bolt

Adjustment

Bolt

Trowel Arm

Adjustment

Fixture

Locking

Bolts

Shim

Distance = .010 in.

5. Make sure that the spring tensioner is in the correct

position to exert tension on the trowel arm.

6. Insert all trowel arms with levers into spider plate (with

bronze bushing already installed) using care to align

grease hole on bronze bushing with grease hole fitting

on spider plate.

7. Lock trowel arms in place by tightening the hex head

bolt with zerk grease fitting and jam nut.

8. Re-install the blades onto the trowel arms.

9. Install stabilizer ring onto spider assembly.

10. Lubricate all grease points (zerk fittings) with premium

"Lithium 12" based grease, conforming to NLG1 Grade

#2 consistency

INSTaLLINg paNS ONTO FINISHeR BLaDeS

These round discs sometimes referred to as “pans” attach

to the spiders arms and allow early floating on wet concrete

and easy movement from wet to dry areas. They are also

very effective in embedding large aggregates and surface

hardeners.

Refer to Figure 40 when installing pans onto finisher blades.

Figure 40. Z-Clip Finisher Pan Instructions

WarNiNg

Lifting/Crush Hazard.

DO NOT lift trowel with

pans attached.

WarNiNg

aLWaYS install pans either on the work area or on an area

that is next to and level with the work area.

DO NOT lift the

trowel when the pans are attached.

Blade

Assembly

Knob,Tie-Down

Z-Clip Pans

Tie-Down,

Blade

Z-Clip Pan