Clip-loc – Metal Sales Clip-Loc Installation User Manual

Page 52

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 2/03

812.246.1935 (Corporate Offi ce) • www.mtlsales.us.com

51

CLIP-LOC

R

AKE

(O

FF

M

ODULE

) O

VER

O

PEN

F

RAMING

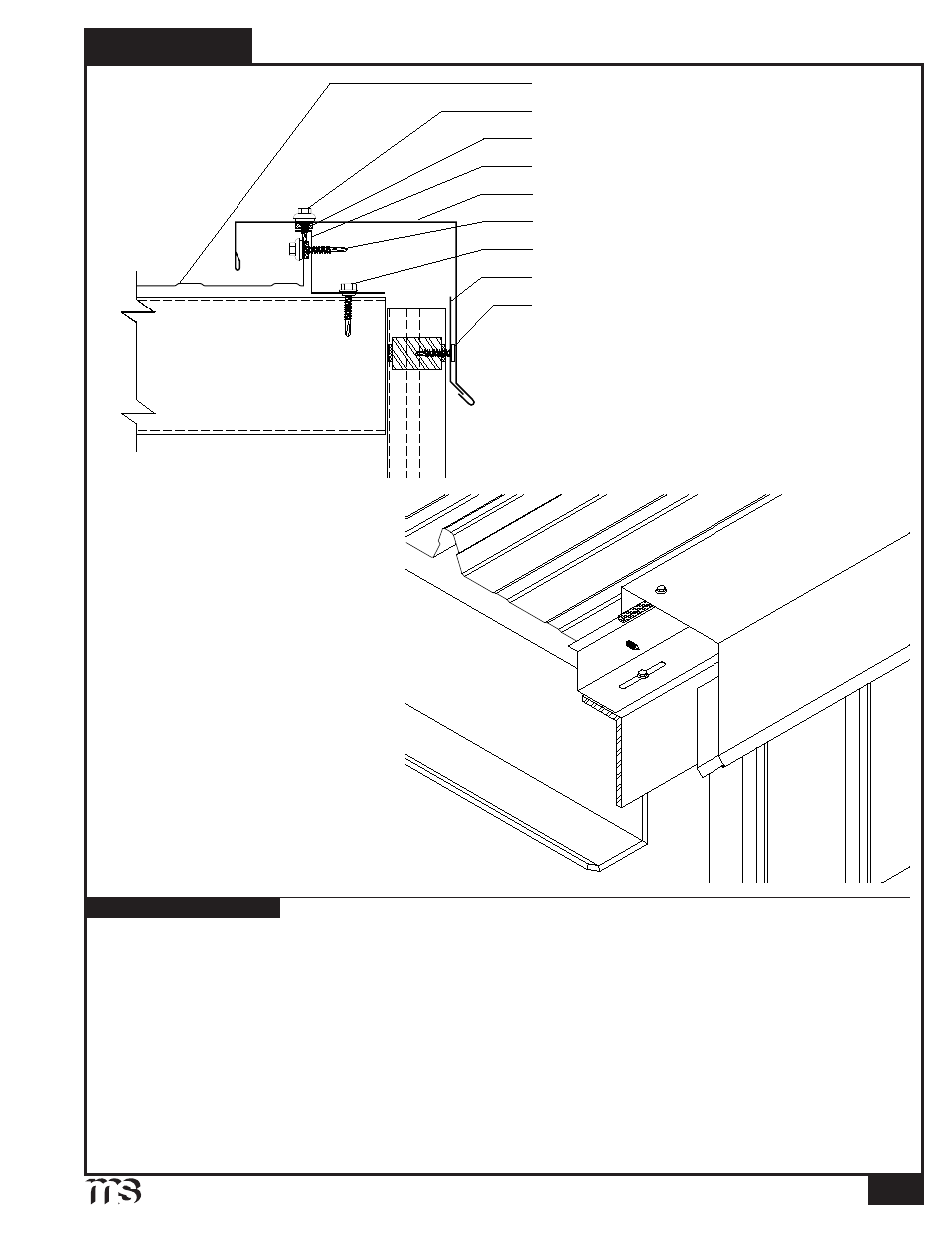

Clip-Loc Floating Rake Zee and Clip-Loc panels must be installed prior to rake installation (see page 44-45). Panel must

be field bent up 1

5

/

8

".

1. Position and install Cleat to wall with appropriate fastener, 1'-0" o.c. Make sure Cleat installation allows for proper Clip-Loc

Rake

attachment.

2. Apply a row of Double Bead Tape Sealant between Floating Rake Zee and field bent panel rib. Fasten field bent panel rib to

Clip-Loc Floating Rake Zee with 12-14 x 1½" SD XL 1'-0" o.c.

3. With Clip-Loc panel properly fastened to Clip-Loc Floating Rake Zee, apply a row of Double Bead Tape Sealant across top of

Floating Rake Zee.

4. Install Clip-Loc Rake flashing by sliding open hem onto Cleat and resting the Clip-Loc Rake flashing on top of Floating Rake

Zee. Fasten through Clip-Loc Rake, sealant, and into Clip-Loc Floating Rake Zee with ¼-14 x

7

/

8

" Stitch XL 1'-0" o.c. Stagger

Stitch fastener so that there is no interference with 12-14 x 1½" SD XL already installed.

5. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2" placing a bead

of tube sealant between the flashings and securing with pop rivets 2

1

/

2

" o.c.

#

1

/

4

-14 x

7

/

8

" Stitch XL (1'-0" o.c.)

Clip-Loc Panel

Cleat

#10-16 x 1" PHD (1'-0" o.c.)

Floating Rake Zee

Clip-Loc Rake

#12-14 x 1

1

/

4

" Shoulder Tech (1'-0" o.c.)

#12-14 x 1

1

/

2

" SD XL (1'-0" o.c.)

Field bend Panel Rib up 1

5

/

8

"

Double Bead Tape Sealant

1:12 Slope

Minimum

INSTALLATION NOTES