Design / installation considerations – Metal Sales Pro-Panel II Installation User Manual

Page 25

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 5/09.

24

POST FRAME

& RESIDENTIAL

DESIGN / INSTALLATION CONSIDERATIONS

Metal Sales’ panels are designed to be installed over open framing and/or directly over a wood substrate (minimum 5/8”)

with 30# felt moisture barrier (or an Ice and Water Shield when required by Local Building Codes).

Always check with local building codes prior to all installations for any additional requirements that may be specific to your

area.

Galvanized and Galvalume panels should not be in contact with, or subject to, water runoff from copper, lead, or uncoated

steel materials.

Condensate water from air conditioning units typically contains dissolved copper. This condensate should be discharged

through a plastic pipe extended beyond the edge of the roof.

GENERAL

CONDITION OF SUBSTRUCTURE

The roof should be inspected for any trapped moisture or structural damage such as bowing or sagging rafters and warped or

loose roof purlins or solid decking. These areas should be repaired prior to installing new metal panels.

Prior to installation, make sure there are no nails or fasteners protruding from the roof framing or wood substrate which could

damage the panels and impede the installation process.

When installed, panel distortion may occur if not applied over properly aligned and uniform substructure.

Whether installing over new or existing roof, the installer should check the roof deck for squareness before installing panels.

Several methods can be used to verify squareness of the structure for proper installation of the panels.

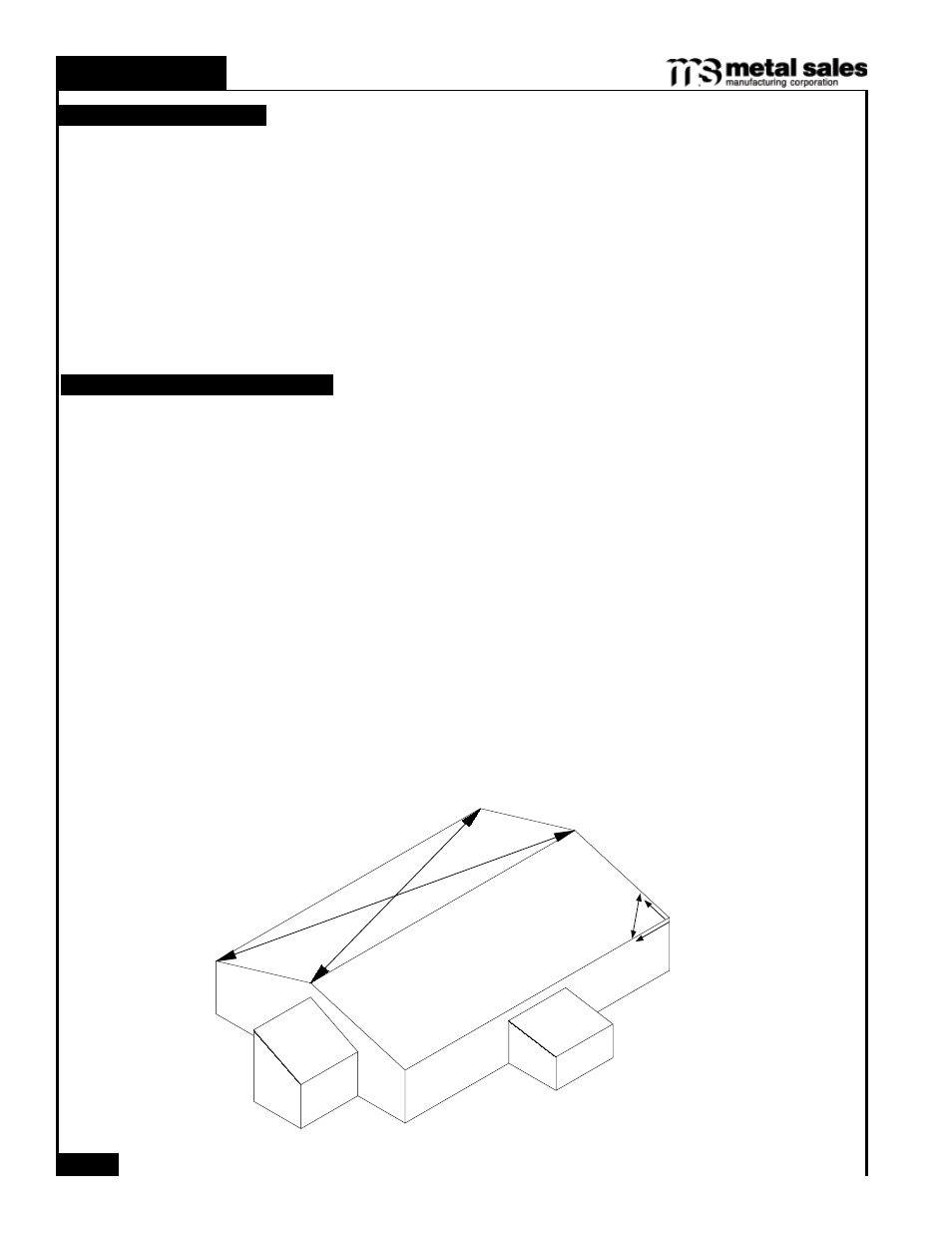

METHOD “A” - One method for checking the roof for squareness is to measure diagonally across one slope of the roof from

similar points at the ridge and eave and obtain the same dimension.

METHOD “B” - The 3-4-5 triangle system may also be used. To use this system, measure a point from the corner along the

edge of the roof at a module of three (3). Measure a point from the same corner along another edge at a module of four (4).

By measuring diagonally between the two points established, the dimension should be exactly a module of five (5) to have a

square corner. Multiple uses of this system may be required to determine building squareness. If the endwall cannot be made

square, the roof system cannot be installed as shown in these instructions.

METHOD A

METHOD B

10

10

4

3

5