Bryant LEGACY 580J User Manual

Page 29

29

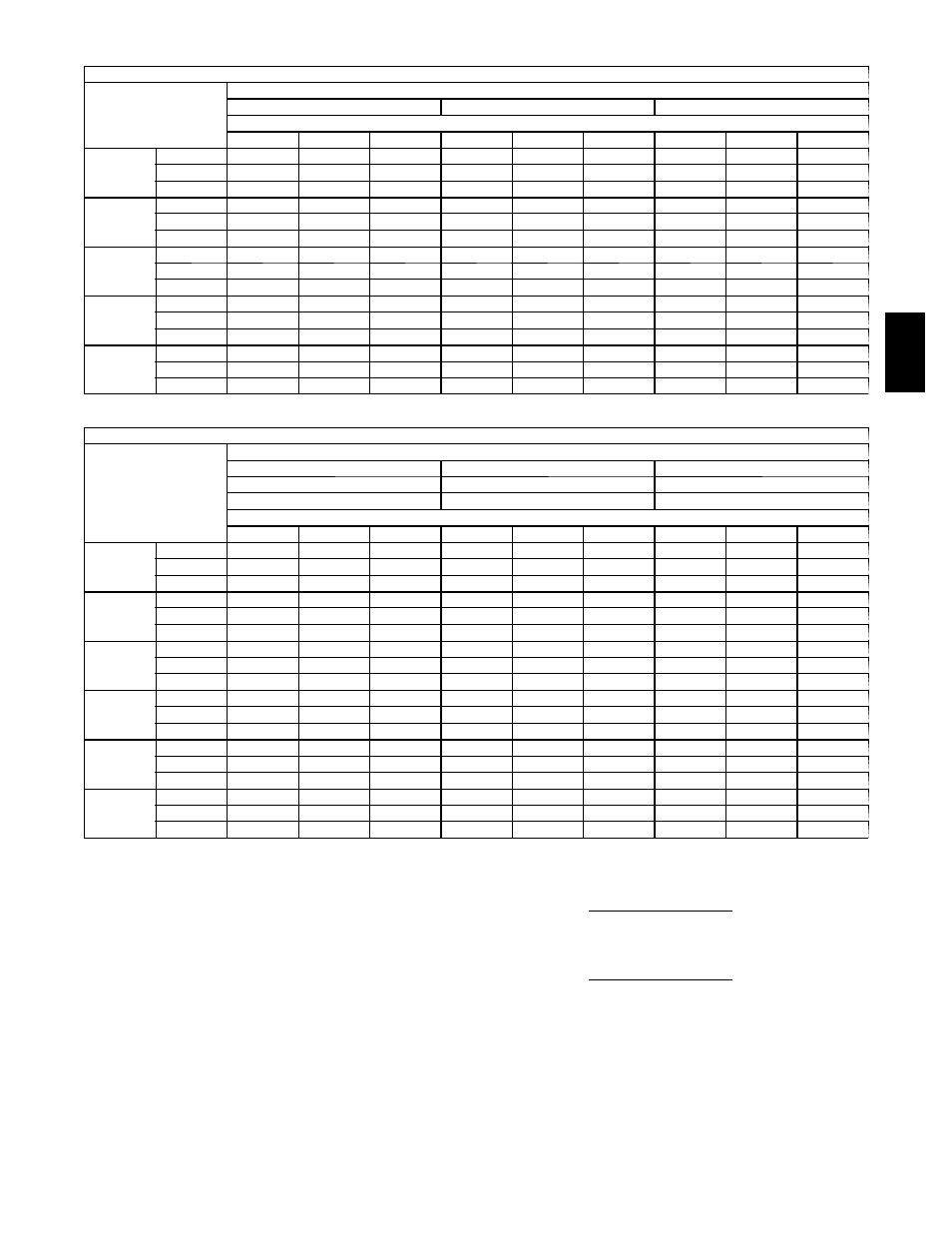

Table 14 – COOLING CAPACITIES

2--Stage Cooling

20 TONS (con’t)

580J024 (20 TONS) --- UNIT WITH PERFECT HUMIDITY IN SUBCOOLING MODE

Temp (F) Air Ent

Condenser (Edb)

AIR ENTERING EVAPORATOR --- CFM/BF

6,000

8,000

10,000

Air Entering Evaporator --- --- Ewb (F)

72

67

62

72

67

62

72

67

62

75

TC

263.0

240.4

217.7

301.0

274.0

246.9

336.9

305.6

274.4

SHC

125.3

151.6

178.0

144.4

171.1

198.0

160.0

186.9

213.9

kW

15.63

15.20

14.65

15.91

15.62

14.98

16.26

15.92

15.21

85

TC

248.2

226.1

204.0

279.2

252.9

226.6

308.4

278.2

248.0

SHC

98.9

131.7

164.5

118.6

152.0

185.3

134.6

168.4

202.2

kW

17.50

17.04

16.50

17.74

17.51

16.75

18.08

17.73

17.03

95

TC

233.4

211.8

190.2

257.3

231.8

206.4

279.8

250.7

221.5

SHC

72.4

111.8

151.1

92.7

132.8

172.9

109.3

149.9

190.6

kW

19.36

18.96

18.35

19.61

19.37

18.67

20.02

19.62

18.97

105

TC

218.6

197.5

176.5

235.4

210.7

186.1

251.3

223.2

195.1

SHC

46.0

91.8

137.7

66.9

113.6

160.4

83.9

131.4

178.9

kW

21.23

20.76

20.18

21.53

21.22

20.52

21.91

21.52

20.77

115

TC

203.7

183.3

162.8

213.5

189.7

165.8

222.7

195.7

168.7

SHC

19.5

71.9

124.2

41.0

94.4

147.9

58.5

112.9

157.2

kW

23.02

22.58

22.02

23.42

23.02

22.38

23.73

23.41

22.57

580J024 (20 TONS) --- UNIT WITH Perfect Humidity IN HOT GAS REHEAT MODE

Temp (F) Air Ent

Condenser (Edb)

AIR ENTERING EVAPORATOR --- Ewb (F)

75 Dry Bulb

75 Dry Bulb

75 Dry Bulb

62.5 Wet Bulb

64 Wet Bulb

65.3 Wet Bulb

(50% Relative)

(56% Relative)

(60% Relative)

Air Entering Evaporator --- Cfm

6,000

8,000

10,000

6,000

8,000

10,000

6,000

8,000

10,000

80

TC

91.50

100.80

109.50

95.80

105.70

112.40

102.30

110.80

118.60

SHC

12.30

31.20

44.50

0.90

15.10

25.70

---6.50

3.60

13.90

kW

14.82

15.01

15.24

15.35

15.45

15.52

15.56

15.65

15.73

75

TC

94.00

103.40

112.00

98.70

108.10

115.10

104.70

113.10

121.10

SHC

13.60

32.40

45.70

2.00

16.00

26.60

---5.60

4.70

15.10

kW

14.90

15.07

15.33

15.43

15.56

15.64

15.69

15.77

15.85

70

TC

96.50

106.00

114.30

100.90

110.60

117.20

107.20

115.80

123.50

SHC

14.50

33.20

45.70

3.30

17.30

28.00

---4.00

5.90

16.20

kW

14.97

15.17

15.41

15.50

15.66

15.75

15.80

15.87

15.94

60

TC

101.80

111.30

119.30

106.20

115.60

122.20

112.60

119.40

128.00

SHC

16.70

35.50

48.60

5.60

19.40

30.30

---1.80

8.20

18.50

kW

15.14

15.32

15.58

15.66

15.88

15.97

16.05

16.10

16.19

50

TC

107.20

116.40

124.30

111.50

120.70

127.30

117.70

125.20

132.90

SHC

18.60

37.60

50.70

8.00

22.00

32.70

0.50

10.50

21.00

kW

15.27

15.46

15.76

15.81

16.10

16.23

16.27

16.34

16.41

40

TC

112.20

121.80

129.20

116.60

125.70

132.00

123.20

130.00

138.00

SHC

21.80

39.50

52.90

10.20

24.40

35.20

2.90

13.00

23.40

kW

15.42

15.63

15.93

15.96

16.32

16.44

16.52

16.57

16.65

LEGEND

Edb --- Entering Dry---Bulb

Ewb --- Entering Wet---Bulb

kW

--- Compressor Motor Power Input

Idb

--- Leaving Dry---Bulb

Iwb --- Leaving Wet---Bulb

SHC --- Sensible Heat Capacity (1000 Btuh) Gross

TC

--- Total Capacity (1000 Btuh) Gross

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

t

ldb

= t

edb

–

sensible capacity (Btuh)

1.10 x cfm

t

lwb

= Wet---bulb temperature corresponding to enthalpy of air

leaving evaporator coil (h

lwb

)

h

lwb

= h

ewb

–

total capacity (Btuh)

4.5 x cfm

Where: h

ewb

= Enthalpy of air entering evaporator coil

580J