Troubleshooting – Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 34

PAGE 34

SG87Sh SuRFACE ShARK FLooR GRINDER

LUBRICATION REQUIREMENTS

Application: SG87SH SURFACE SHARK

Parts Required:

1 each, standard grease gun filled with one of the

following: ESSo beacon 325, Shell

Alvania #2, Chevron SRI, or equivalent.

1 each, container of dry film lubricant.

1) Lubricate the caster wheel bearings with a dry film

lubricant only. Dry film lubricants dry immediately upon

contact. use sparingly. Excess lubricant will attract the

fine grained, powdered materials produced during use

of the Floor Grinder that can directly affect bearing

service life.

Do not lubricate the caster wheels with any type of

grease material. Grease will attract foreign material

accumulations that can accelerate bearing wear.

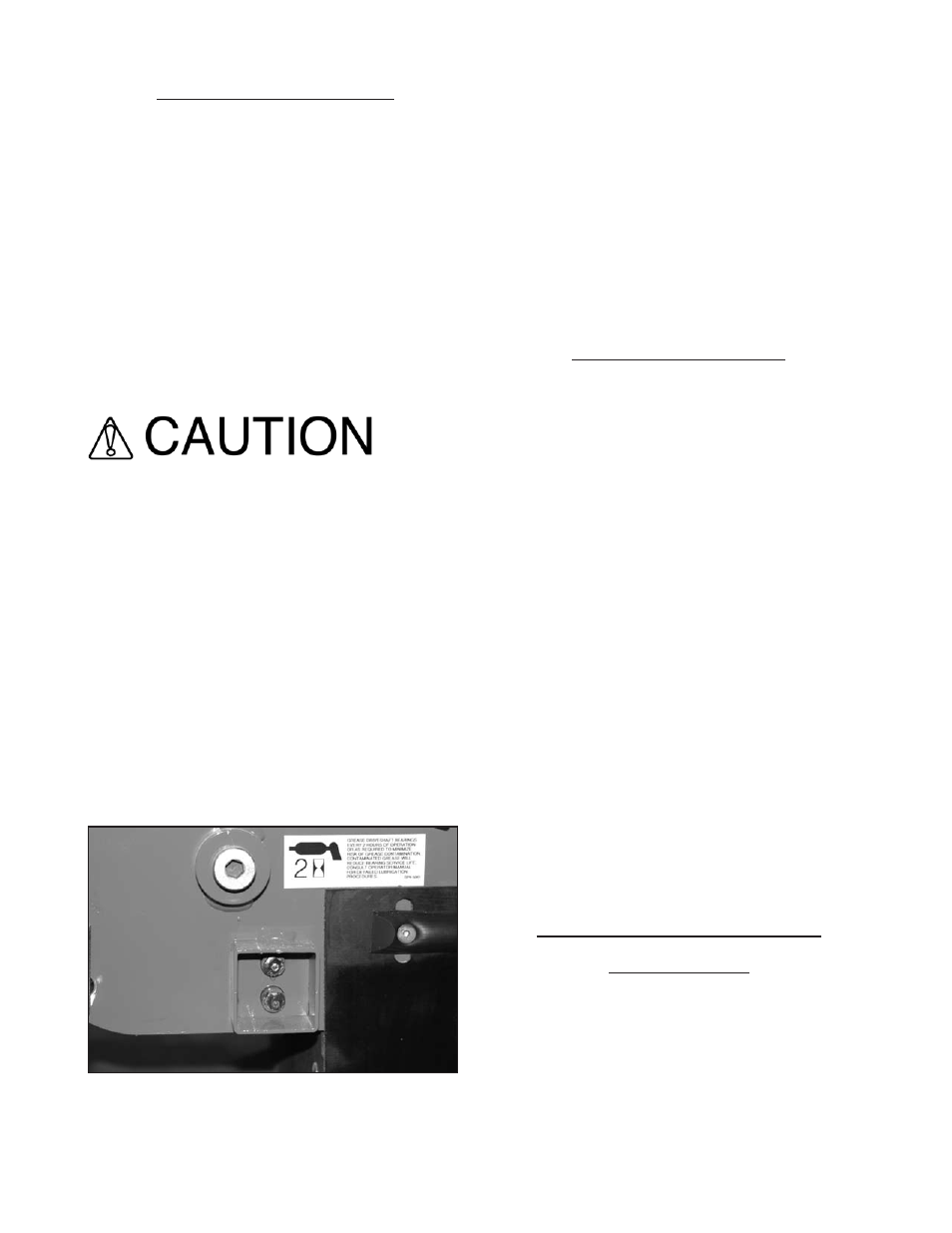

2) The transmission shaft is supported by extra capacity,

ball bearings. bearing are lubricated at the time of

manufacture and do not require additional servicing

when placing the unit in initial service. The remote-

type, central lubrication system is a convenient method

for providing lubrication to bearings. FIGuRE29. Zerk

grease fittings can promote improper service schedules

and an excessive amount of overgreasing. Excess

grease escaping from around the bearing insert seals

will attract foreign material accumulations that can

drastically shorten seal life. Excessive amounts of

grease in the bearing race cavity can actually increase

friction and resulting heat increases that can also

dramatically shorten bearing service life.

FIGuRE 29

3) Standard bearing greasing intervals will range

from once every 8 hour work day to approximately

once every work week. Always maintain sufficient

grease around the circumference of the bearing insert

to provide its self-aligning feature and prevent the

formation of corrosion.

5) Do not apply belt dressing materials to the v-belt for

the purpose of minimizing slippage. These products

typically attract foreign material accumulations that

can accelerate component wear. Excessive v-belt

slippage can be eliminated with proper v-belt tension

and alignment.

ELECTRIC MOTOR SERVICE

Application: SG87SH SURFACE SHARK

The electric motor is capable of operating for many

years with a reasonably small amount of maintenance.

before attempting to service the motor, disconnect

the Floor Grinder from the power source. Clean

the motor surfaces periodically, preferably with a

vacuum cleaner. heavy accumulations of dirt and

dried materials will result in overheating and premature

failure of the motor.

The electric motor is equipped with higher capacity

ball bearings and under normal service and ambient

temperatures, should not require relubrication for many

years.

The seals utilized with the motor are intended to deliver

a longer service life in a concrete dust environment.

When replacing the seals, utilize only components

meeting the original factory specifications.

If you feel that the motor requires relubrication, contact

the local representative of the motor manufacturer

for specific information. Refer to your local yellow

Page listing or website. Additional service can also be

obtained from local service centers which are members

of the Electrical Apparatus Service Association

(EASA).

TROUBLESHOOTING

ELECTRIC MOTOR

Application: SG87SH SURFACE SHARK

MoToR FAILS To START

oN/oFF switch in the oFF position. Turn the switch to

the oN position.