Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 23

SG87Sh SuRFACE ShARK FLooR GRINDER

PAGE 23

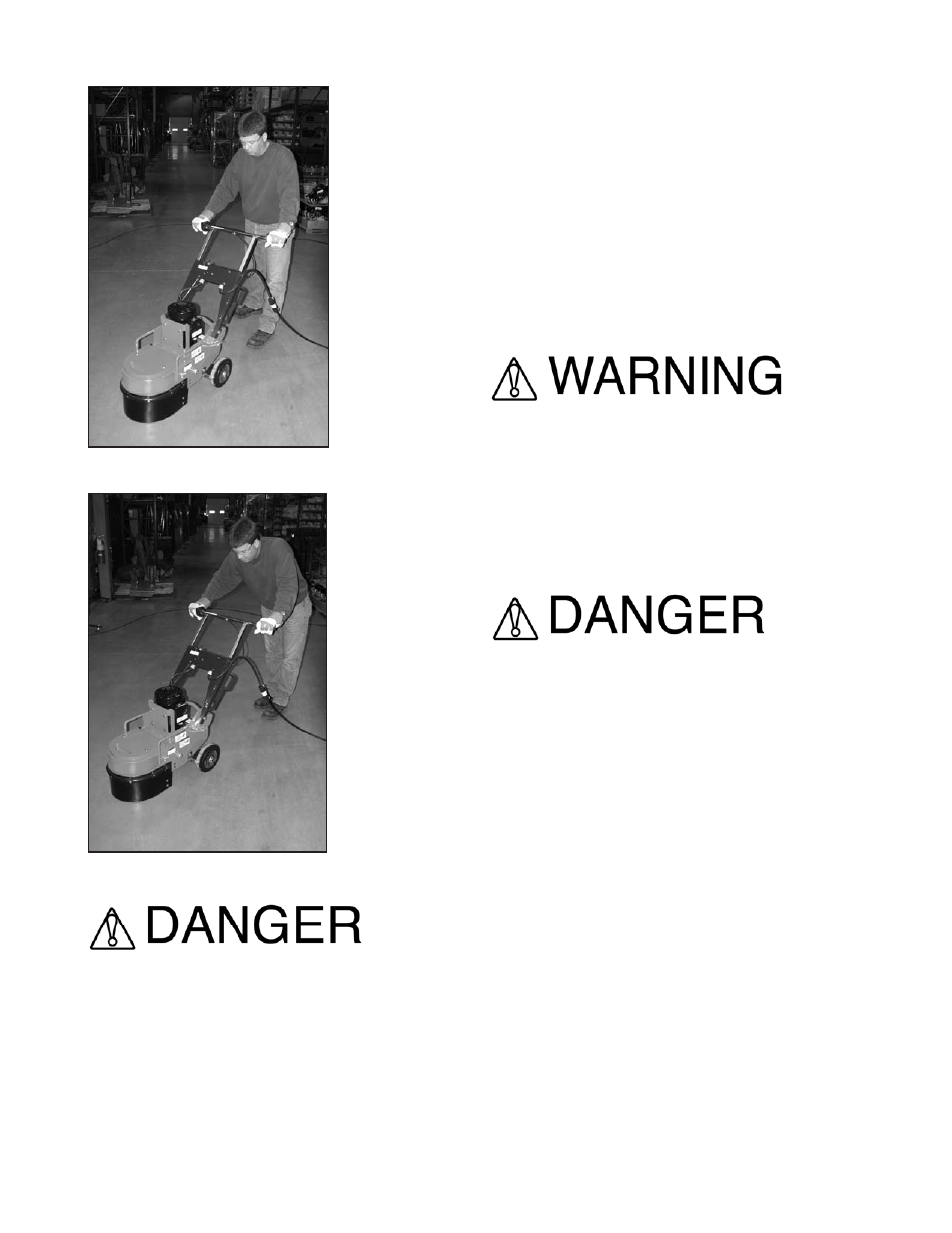

FIGuRE 17

FIGuRE 18

Maintain the operator handle and motor control

handle grip areas in good condition and free of

moisture, pitch, oil or grease. Wear gloves to

improve your grip. Bent and damaged handles, a

motor control with damaged or no grip aggravate

the torque effect upon the operator by limiting

control and comfort. Do not operate the Floor

Grinder until such damage has been repaired and/

or replaced. Damage to property and/or personal

injury can result.

4) A multi-accessory attachment that comes in direct

contact with a protruding obstruction from the floor

can result in unexpected, rapid and jerky directional

movement of the machine. In most operating situations,

direct contact with a protruding obstruction from the

floor will result in the multi-accessory attachment

becoming dislodged from the aluminum disc. This

occurrence is intended to protect the Floor Grinder

from excessive damage and allow the operator to

remain in proper control of the machine.

ALWAYS MAINTAIN PROPER CONTROL OF THE

FLOOR GRINDER. IF AN OPERATOR LOOSES

CONTROL OF THE MACHINE, A “RUNAWAY”

FLOOR GRINDER CAN RESULT IN PROPERTY

DAMAGE

AND/OR

PERSONAL

INJURY.

THE ELECTRIC MOTOR IS INTENDED TO

AUTOMATICALLY STOP IF THE OPERATOR FAILS

TO MAINTAIN PROPER CONTROL AND RELEASES

THE STARTER CONTROL GRIP.

WHEN OPERATING THE FLOOR GRINDER ON

ABOVE GROUND FLOOR LEVELS, EXERCISE

EXTREME CAUTION TO PREVENT LOSS OF

CONTROL THAT COULD ALLOW THE MACHINE

AND/OR OPERATOR TO FALL DOWN TO LOWER

LEVELS. SUCH AN OCCURRENCE CAN RESULT

IN PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

5) Productivity rates with the various multi-accessory

attachments can be increased with the addition of

external weight being applied to the area over the

aluminum disc. The maximum allowable external

weight for the SG87Sh is 150 lbs (68 kg). Exceeding

this figure can result in permanent structural damage to

the Floor Grinder. Provisions for securing the weight by

the means of strapping or other, appropriate methods

is provided. FIGuRE 19.