Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 19

SG87Sh SuRFACE ShARK FLooR GRINDER

PAGE 19

UNEXPECTED MACHINE START UP CAN RESULT

IN PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

TRANSPORTING THE FLOOR GRINDER

Application: SG87SH SURFACE SHARK

The Floor Grinder has an operational weight that

prohibits one person from loading and/or unloading it

alone by conventional, physical efforts.

DO NOT ATTEMPT TO LIFT THE FLOOR GRINDER

UP INTO A TRANSPORTATION VEHICLE WITH

THE USE OF ONE PERSON ALONE. DO NOT

ATTEMPT TO LOWER THE FLOOR GRINDER FROM

A TRANSPORTATION VEHICLE WITH THE USE

OF ONE PERSON ALONE. LIFT AND/OR LOWER

THE FLOOR GRINDER ONLY BY THE USE OF A

POWER TAILGATE UNIT, A SUITABLE HOIST UNIT

OF PROPER CAPACITY AND/OR CONFIGURATION

OR BY THE USE OF A PROPER QUANTITY OF

PERSONNEL IN PROPER PHYSICAL CONDITION.

1) A lifting bail device can be used to facilitate lifting by

a mechanical device incorporating a chain and suitable

attachment device. The location of the lifting bail may

not always locate the exact position of the center of

gravity for the Floor Grinder. Lifting handles are also

provided on both sides of the transmission case.

These handles can be utilized by personnel whenever

lifting/lowering the Floor Grinder or as attachment

points for a chain sling whenever a suitable hoisting

device is utilized. The SG87Sh Floor Grinder can also

be lifted or lowered by the use of a fork lift time being

inserted between the handles and transmission case.

EXERCISE EXTREME CAUTION WHEN UTILIZING

A MECHANICAL DEVICE FOR LIFTING THE FLOOR

GRINDER. UTILIZE THE MECHANICAL DEVICE

IN ACCORDANCE TO BOTH ITS STATED STATIC

AND DYNAMIC LOADING ENVELOPES. DO NOT

UTILIZE THE MECHANICAL DEVICE UNTIL THIS

INFORMATION IS PROPERLY KNOWN AND

UNDERSTOOD BY ALL APPLICABLE PERSONNEL.

FAILURE TO PROPERLY UTILIZE THE MECHANICAL

DEVICE CAN RESULT IN PROPERTY DAMAGE

AND/OR PERSONAL INJURY.

2) To minimize the possibility of damage to the Floor

Grinder, always transport in its normal, upright position.

All equipment must be secured in/on vehicles with

suitable strapping or tie-downs. Personnel should not

be transported in the same compartment as equipment

and fuel supplies.

ADJUSTING THE OPERATOR HANDLE HEIGHT

Application: SG87SH SURFACE SHARK

The SG87Sh S Floor Grinder incorporates a telescoping

type handle that can be adjusted to compensate for

variances in operator heights. handle height can be

infinitely varied between the stop limits. No external

tools are required. Correct handle height can increase

overall machine productivity and reduce operator

fatigue.

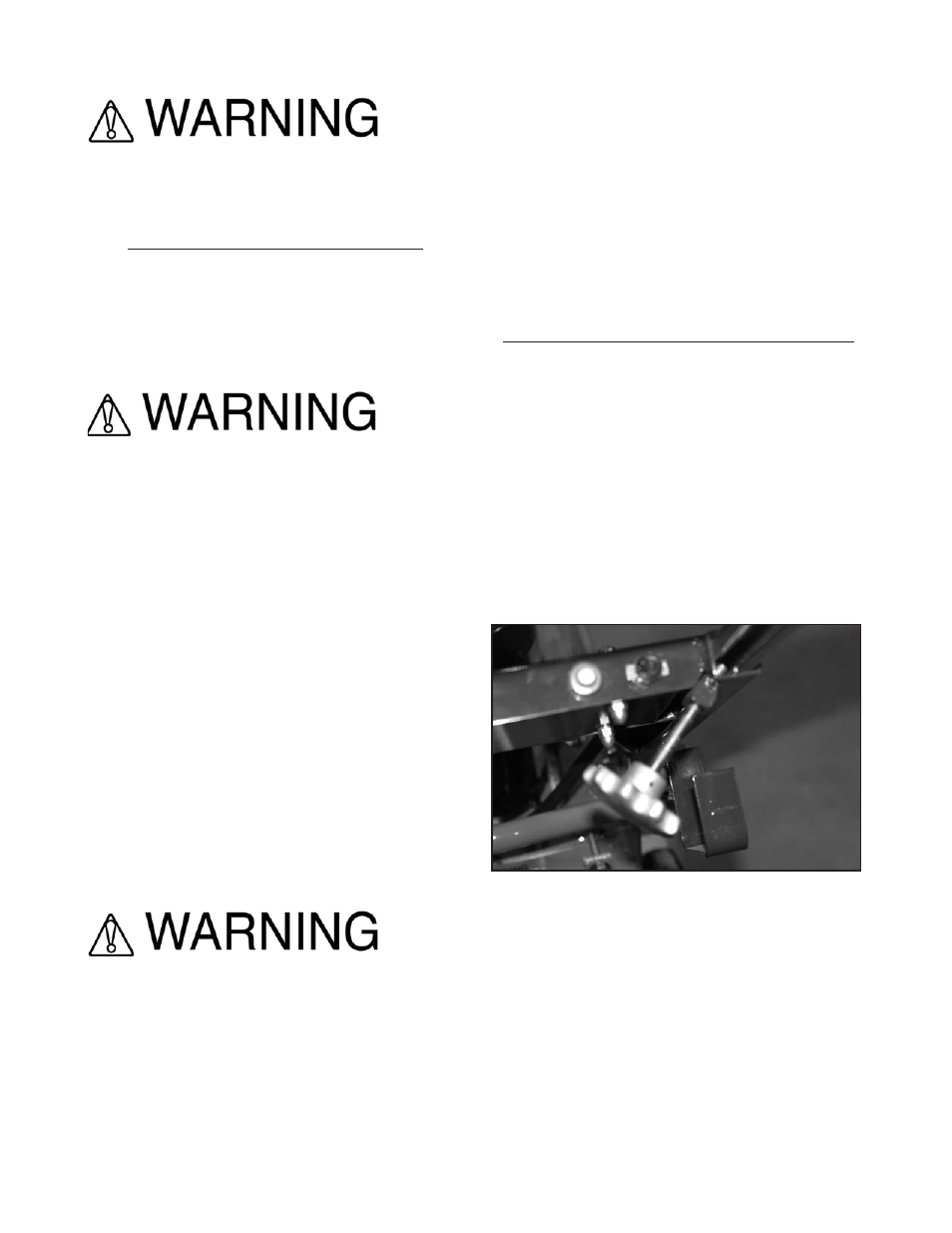

1) Loosen the handle knobs located at the rear of the

handle. Extend the knobs out approximately 1/2 inch

(13 mm). FIGuRE 12.

FIGuRE 12

2) Position the operator handle grips at a height

convenient to the specific operator. In most

configurations, the operator handle grips will be at

approximately waist level.

3) Tighten the handle knobs finger tight. Determine the

adjustable section of the operator handle is properly

secured tight against the fixed section.