Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 27

SG87Sh SuRFACE ShARK FLooR GRINDER

PAGE 27

The highest degree of surface regularity is found

among the defined traffic floors. Defined traffic floors

allow the designer and contractor to focus on a limited

number of critical areas. When a defined traffic floor

is out of tolerance, it is relatively easy to identify the

defects for correction---usually by employing a grinding

process.

How to Define Surface Regularity.

Since the middle 1980s, new methods of defining

surface regularity have been adopted as national

standards. older methods will continue to be utilized,

although they are less effective. The following methods

will be discussed:

1) The F number system for random traffic floors

2) The TR34 system for defined traffic floors

both methods are not of equal value. For random

traffic floors, F numbers provide the most complete and

consistent system. For defined traffic floors, the TR34

system is superior.

The F number system utilizes a pair of numbers to

define surface regularity. The flatness number, oFF,

is based upon the curvature over a horizontal distance

of 24 inches. The levelness number, Fl, is based upon

the floor slope over a horizontal distance of 10 feet.

The standard test for F numbers is specified in ASTM

E1155 and/or most recent version.With both oFF and

Fl, higher numbers mean greater surface regularity.

Though the scale ranges from zero to infinity, almost

all floors have F numbers between 10 and 100 for both

flatness and levelness. Since the scale is linear, an

oFF50 floor is exactly twice as flat as an oFF25 floor.

Most F number specifications are written in a two

tier format. The overall F numbers apply to the floor

taken as a whole. The local F numbers apply to each

individual slab and are usually only one half to two

thirds the overall values.

The overall F numbers are not just simple averages.

ASTM E1155 covers how to combine F numbers.

The two tier format encourages contractors to achieve

good surface regularity while allowing for minor defects.

The attempt is to pour the entire floor to the specified

overall F numbers. If, for instance, the construction crew

has a bad day and fails to meet the specified overall

numbers for the slab, the slab can still be accepted

provided it meets the specified local numbers. Such

an occurrence serves as a warning to the crew that it

must strive for a better performance on later slabs, so

as to bring the overall F numbers up to the specified

values. If a slab fails to meet even the specified local

numbers, it must be repaired or replaced, but such

failures seldom occur if all parties understand what is

expected from the start.

Designers are not obligated to use this two tier format.

Some designers specify a single F number pair (oFF

and Fl) which applies to each individual slab. but this

also raises the risk that slabs will be rejected.

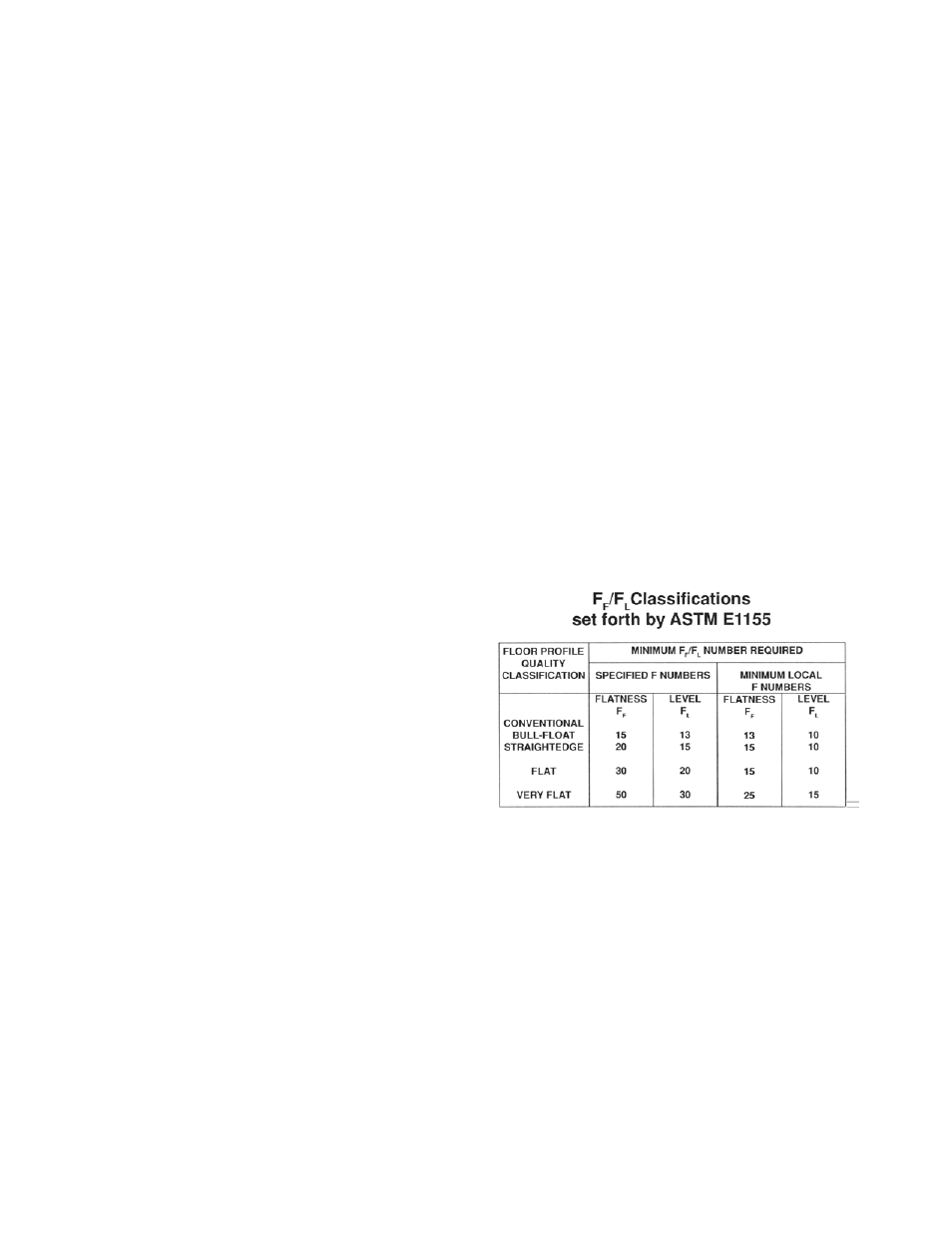

FIGuRE 21 depicts the overall and minimum F numbers

for various floor classes. The floor classification is

from the American Concrete Institute. Although the F

number system is only a few years old, it offers these

advantages:

a) The system controls both flatness and levelness.

b) There is a standard test method.

c) The system recognizes the statistical nature of

profile testing on random traffic floors.

d) The system is infinitely variable.

FIGuRE 21

one of the major limitations of the F number system is

that it does not control the surface regularity at joints.

because joints are statistical anomalies, the standard

test method forbids measurements within 24 inches.

The designer specifying by F number has two methods

to accommodate the problem. The first solution is

to locate joints at locations where surface regularity

is not important. The second solution is to design

specifications for the joints themselves.