Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 15

SG87Sh SuRFACE ShARK FLooR GRINDER

PAGE 15

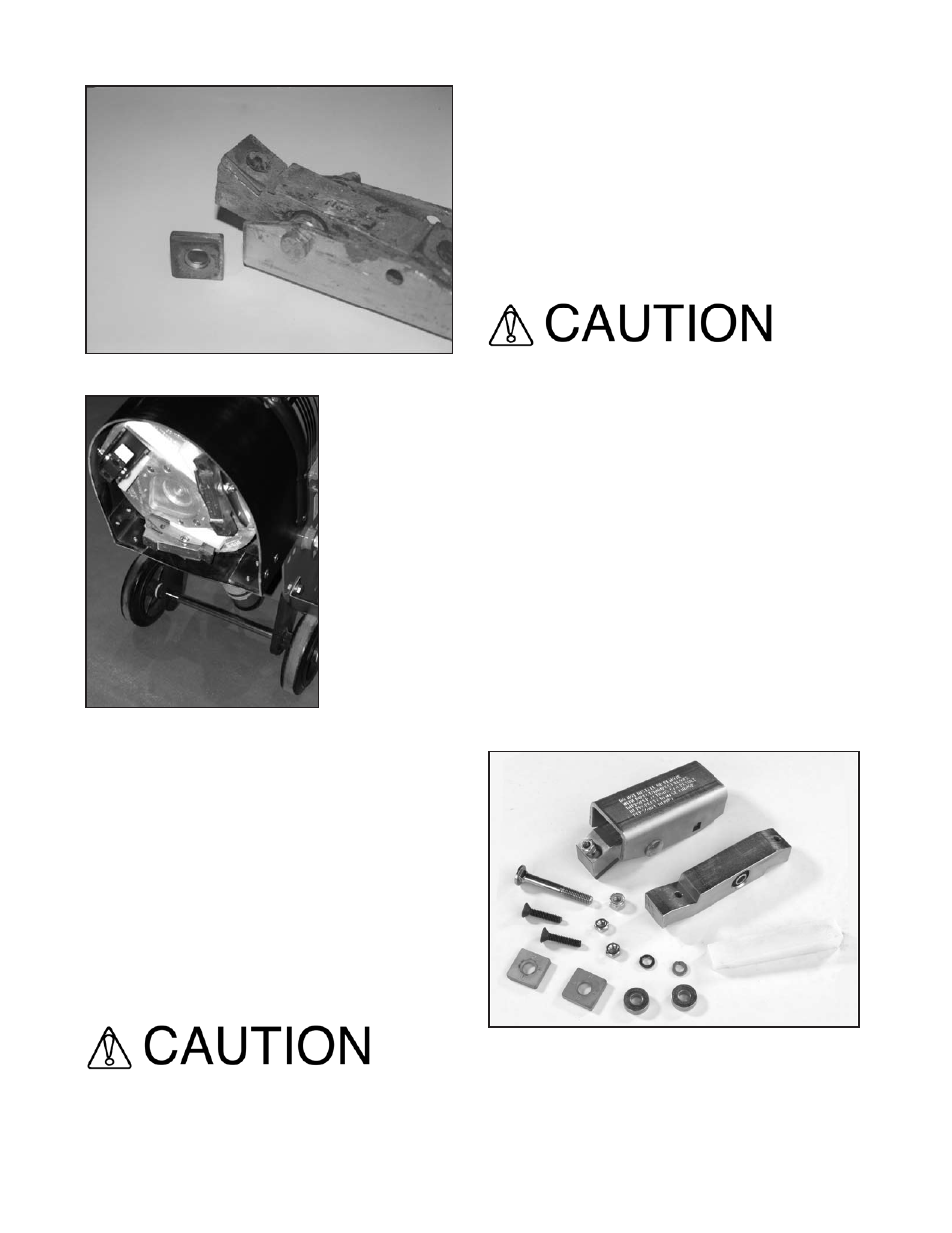

FIGuRE 4

FIGuRE 5

To index the tungsten carbide insert, proceed as

follows:

Tools required:

1 each, 5/32 inch Allen wrench.

1 each, 7/16 inch wrench.

1) Clean the ShARK TooTh unit with a suitable safety

solvent to remove excess material build-up. Remove

as much foreign material as possible from the female

hexagon socket area of the cap screw. This will allow

the wrench to make full contact and maximize the

torque transfer to the cap screw.

Follow all safety precautions for the safety

solvent.

2) Remove the cap screw from the unit. Clean the

newly exposed areas of the insert and ShARK TooTh

unit with the safety solvent. Clean and inspect the

threaded holes found in older units for excess wear.

ShARK TooTh units feature a through hole design.

3) Index the insert to expose a new edge. Reinstall the

cap screw (lock washer and hexagon nut on new style

units) and apply a torque value that properly seats the

insert firmly against the body of the unit.

An insufficient seating torque value will allow

the insert to become loose from the unit body,

resulting in premature component wear and

improper scraping action. An excessive torque

value will strip the threads of the cap screw or unit

body.

4) Determine that the unit body is free to rotate about

the 5/16 inch diameter cap screw that retains the body

to the unit. A body that does not freely rotate indicates

that a material build-up exists between the rubber

mount and retaining cap screw. This build-up must

be removed by disassembling the body from the unit

and cleaning all contact areas with the safety solvent.

FIGuRE 6.

The ShARK TooTh system is designed to be installed

with the edge of the tungsten carbide inserts facing the

direction of rotation. Markings are provided to indicate

proper direction of rotation.

FIGuRE 6