Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 31

SG87Sh SuRFACE ShARK FLooR GRINDER

PAGE 31

4) While gripping the cutout in the external weight,

slide the weight/belt guard away from the electric motor

approximately 1 inch. This will release the cover from

the forward catch mechanism.

5) Remove the weight/belt guard from the main frame.

Clean the inside of the belt guard with an appropriate

solvent. Store in an appropriate location.

Observe all applicable safety precautions for the

solvent.

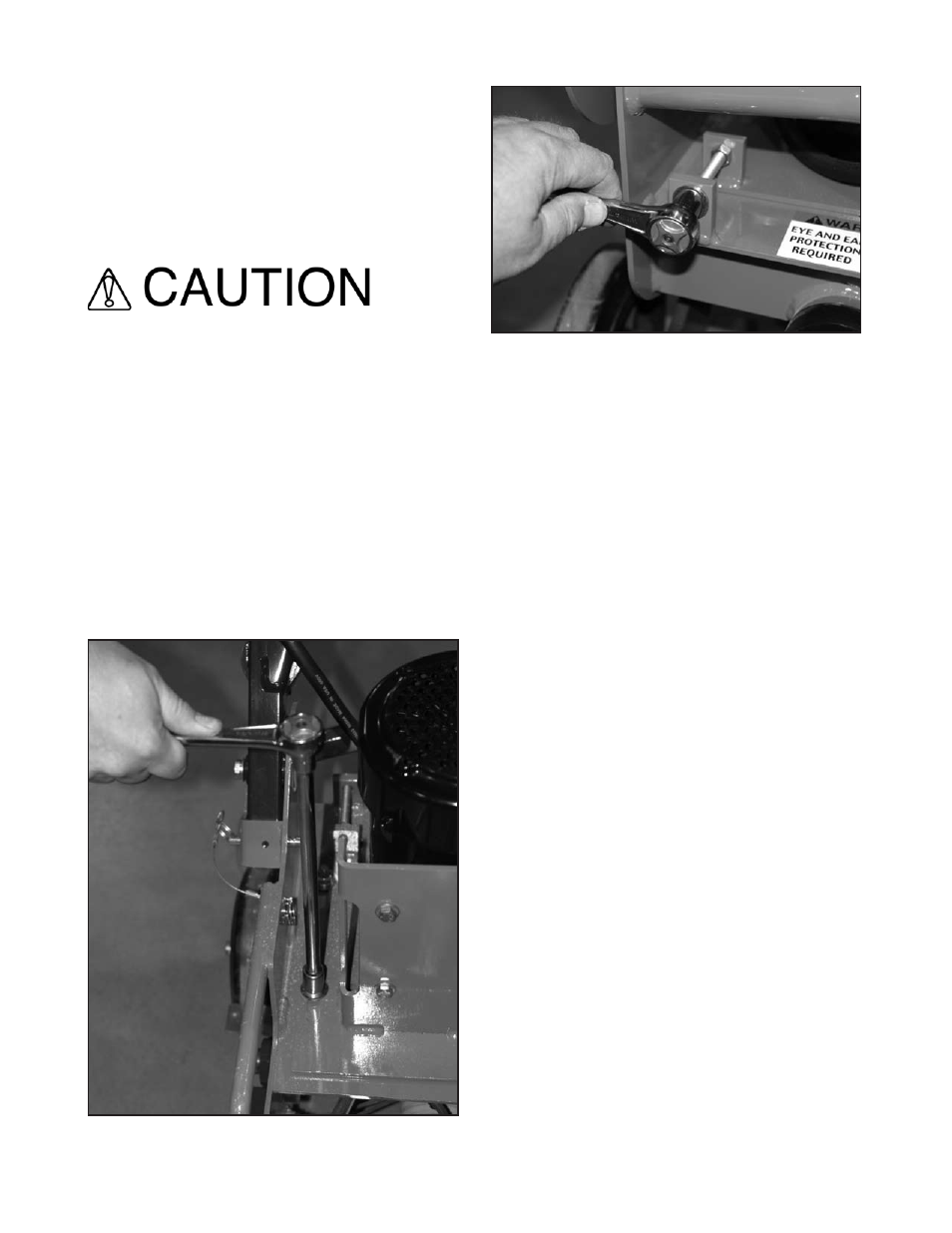

6) using the ratchet, long extension and 9/16 socket,

loosen the hexagon nuts that retain the electric motor

mounting plate to the main frame. FIGuRE 24.

7) using the 9/16 inch wrench, loosen the 3/8 inch

hexagon jam nuts from the motor mounting plate.

FIGuRE 25.

8) With the ratchet and 9/16 inch socket, rotate the

mounting plate take-up screws counterclockwise to

loosen the v-belt and allow the electric motor to slide

forward toward the front of the main fame. FIGuRE

25.

FIGuRE 24

FIGuRE 25

9) Remove the worn v-belt from the pulleys. Inspect

the electric motor and transmission pulleys for wear

and damage.

a) Do not install a replacement v-belt if any pulley has

an excessively worn groove. Such a pulley should be

replaced with a factory approved replacement part to

insure proper belt fit. operating a replacement v-belt

in a worn pulley groove will accelerate wear, reduce

horsepower and torque levels while significantly

reducing component service life.

b) If a replacement pulley is required, remove and

reinstall with a factory approved replacement part. Refer

to CHECKING V-BELT TENSION AND ALIGNMENT

for information relative to maintaining proper v-belt

tension and pulley alignment.

c) A v-belt should never be forced over a pulley. More

belts are broken from this cause than from actual

failure in service.

d) Install the replacement v-belt, Part# Mb45.

e) Keep the belt as clean and free of foreign materials

as possible. Do not use belt dressing.

10) using the ratchet and 9/16 inch socket, rotate

the motor mount take-up screws clockwise until the

v-belt has enough tension to not allow it to fall off the

pulleys.

11) Refer to CHECKING V-BELT TENSION AND

ALIGNMENT for information relative to maintaining

proper v-belt tension and pulley alignment.

12) When correct v-belt tension and pulley alignment

is attained, tighten the hexagon nuts that retain the

motor mount to the main frame.