Marshalltown SG87SH SURFACE SHARK Floor Grinder User Manual

Page 22

PAGE 22

SG87Sh SuRFACE ShARK FLooR GRINDER

FIGuRE 16

11) Grasp the operator handle with firm grip;ping.

When starting the electric motor, apply a down force

directly to the operator handle to help reduce the

amount of machine weight against the work surface.

Rotate the starter control grip with the right hand to

start the electric motor. Reduce the amount of applied

down force on the operator handle as the electric

motor attains its operational speed. The electric motor

will require additional time to help compensate for the

additional starting amperage required.

AS SOON AS THE ELECTRIC MOTOR HAS STARTED,

THE OPERATOR MUST BE IN A POSITION TO

ASSUME DIRECT AND FULL CONTROL OF THE

FLOOR GRINDER. FAILURE TO ASSUME DIRECT

AND FULL CONTROL CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

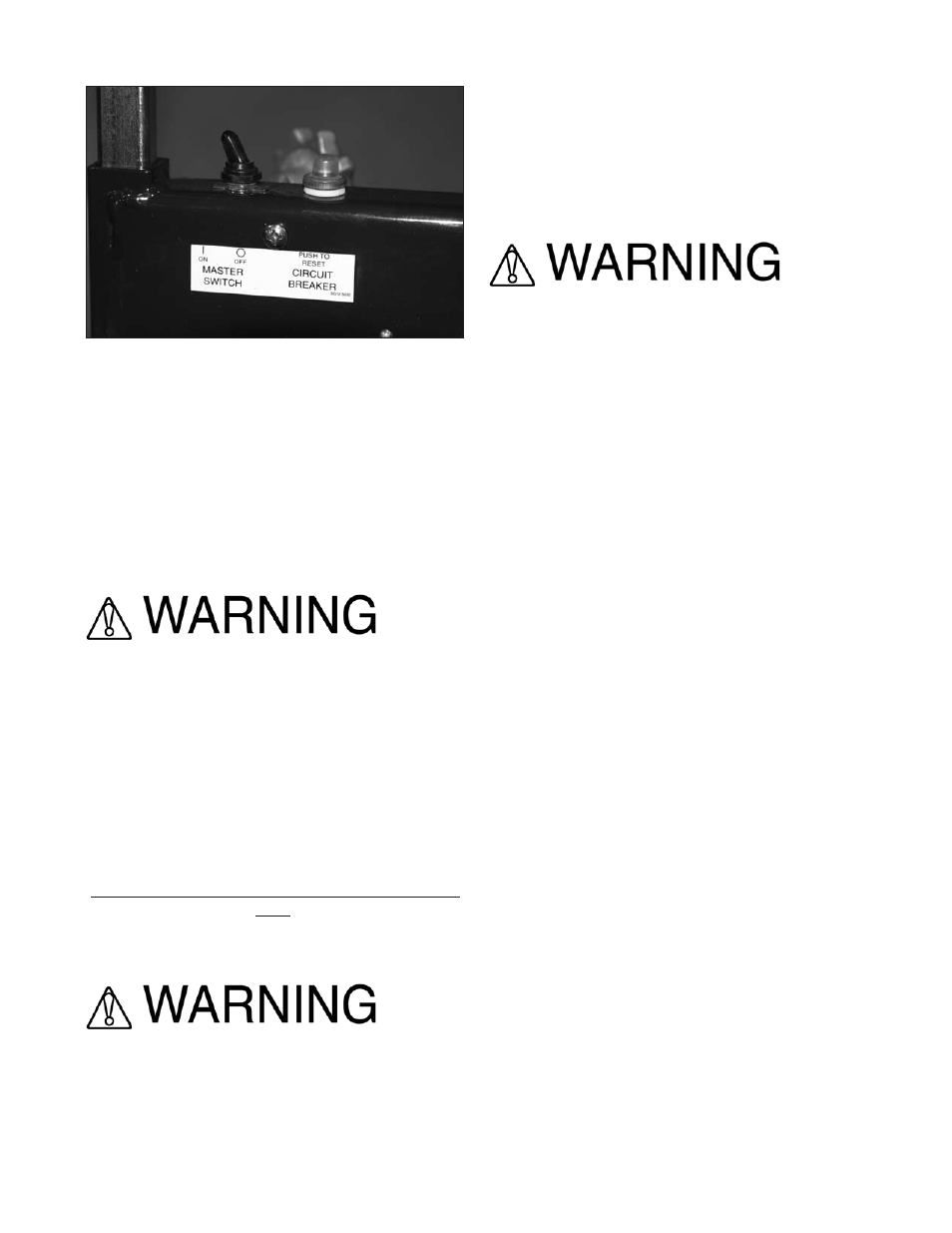

12) The Floor Grinder is stopped by rotating or

releasing the starter control grip with the right hand to

the oFF position. When not in use, turn the oN/oFF

master switch to the oFF position.

OPERATING THE FLOOR GRINDER ON THE JOB

SITE

Application: SG87SH SURFACE SHARK

THE GRINDING PROCESS PRODUCES EXCESSIVE

NOISE, VIBRATION AND FLYING DEBRIS. ALL

OPERATORS AND WORK PERSONNEL IN THE

VICINITY OF THE FLOOR GRINDER MUST WEAR

APPROPRIATE SAFETY EYE WEAR AND HEARING

PROTECTION DEVICES. OTHER SAFETY APPAREL

AND/OR PROCEDURES, DEEMED NECESSARY

BY SUPERVISORY PERSONNEL MUST ALSO BE

WORN AND/OR PRACTICED BY ALL APPROPRIATE

PERSONNEL.

EXERCISE EXTREME CAUTION WHEN OPERATING

THE FLOOR GRINDER IN THE VICINITY OF DECK

INSERTS, PIPES, COLUMNS, OPENINGS, LARGE

CRACKS, UTILITY OUTLETS OR ANY OBJECT

PROTRUDING FROM THE SURFACE. CONTACT

WITH SUCH OBJECTS CAN LEAD TO LOSS OF

MACHINE CONTROL, RESULTING IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

1) The Floor Grinder incorporates a single rotating

disc for mounting a wide variety of multi-accessory

attachments.

2) The single disc of the SG87Sh Floor Grinder rotates

in a clockwise direction as viewed by the operator. This

action produces a torque effect that, during operation,

is counteracted by both the wheels and operator.

Reaction to the torque effect will attempt to move the

Floor Grinder in a counterclockwise direction. Proper

operator position can reduce the amount of torque

effect experienced by the operator. Assume a position

that allow exercising reactive “body english” against

the torque effect created by the specific process. Keep

upper arms as close to the upper body as possible to

maximize mechanical leverage. An operator should

position his back as vertical as possible by bending the

legs as required. Positioning the left foot ahead of the

right foot at a comfortable distance will enhance proper

body position. Maintaining proper operating position

is one of the most IMPoRTANT and EFFECTIvE

procedures for controlling the torque effect. Improper

operating positions only aggravate the effects of the

torque effect upon the operator. FIGuRE 17 depicts

a proper operator position. FIGuRE 18 depicts an

improper operator position.