Software implementation and parameter setting – Lenze 931W User Manual

Page 44

Software implementation and parameter setting

Travel data sets menu

Controller type

5

44

HB 13.0001-EN 3.0

This controller type produces the position setpoint set in relation to the reference point.

The position setpoint can be entered on the right next to the field for the controller type,

whereby the value always refers to the unit displayed above the checkbox for the position

value. The sign of the position setpoint is defined by the selection ”Negative/positive

direction”.

ƒ

Relative position

”Relative position” alters the position round the set position setpoint value relating to the

absolute position value, which is valid at the start of the travel data set. In the case of

”Setpoint positive”, an addition to the current position setpoint is effected; in the case of

”Setpoint negative”, a subtraction is effected. The relative position setpoint can also be

entered relating to the specified unit in the checkbox on the right next to the field for the

controller type.

ƒ

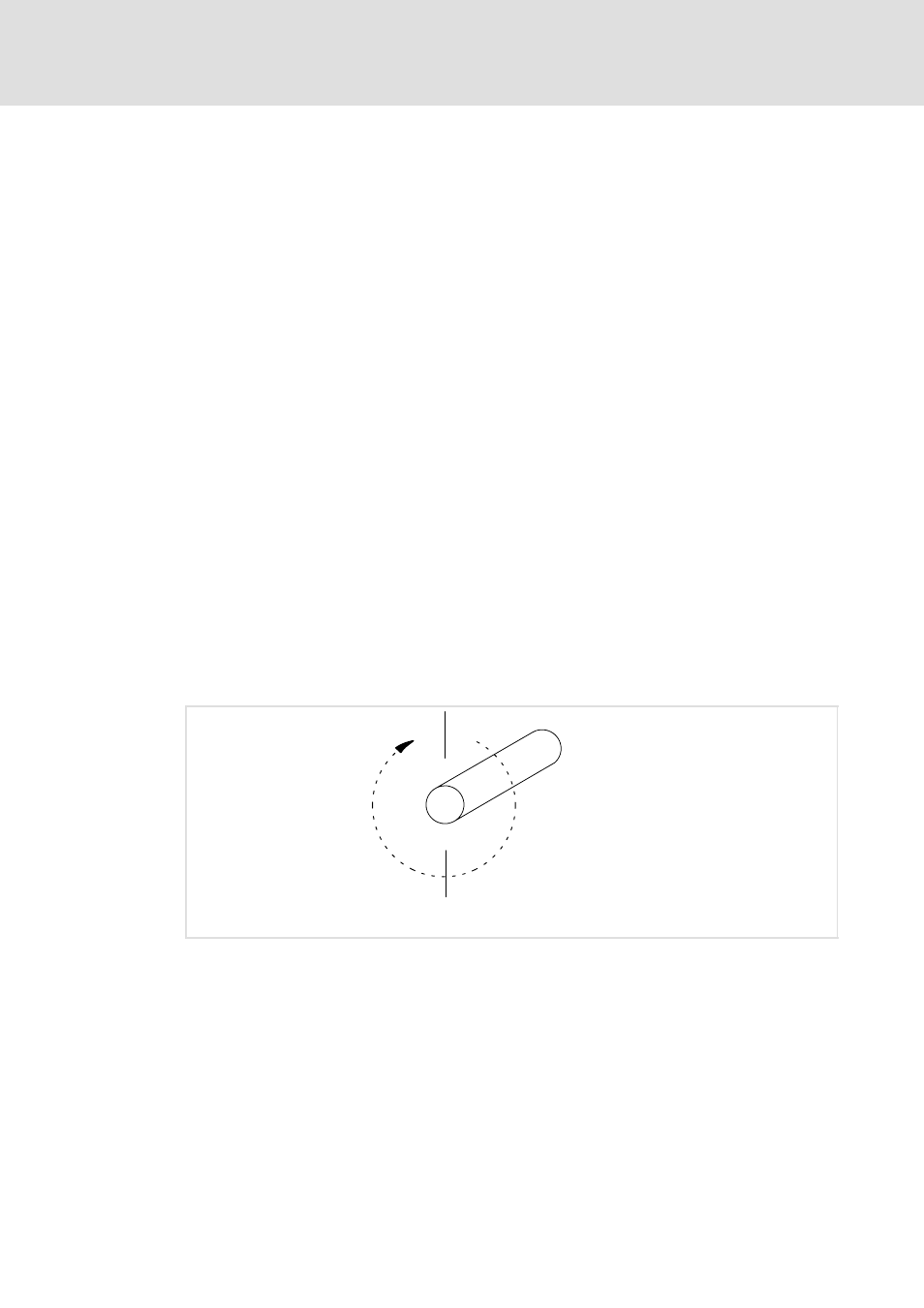

Modulo position

The modulo positioning presents a specific positioning type for rotary table applications.

This operating mode can only be selected if the option ”Rotary axis/modulo” has been

selected on the ”System” tab. In this operating mode, a revolution of the rotary table is

classified into a range of 2048 to -2048 increments. The gearbox factor (see ”Service” tab)

or a conversion factor (see ”System” tab) is considered in this connection.

All target positions are apportioned to this classification. The drive follows the defined set

position on the shortest path from the actual position to the set position. For instance, in

the case of a setpoint selection of 4096 increments, the drive traverses to the position of

0 increments. As soon as the position control end time (see ”Controller” tab) has been

reached, the drive is switched to a deenergised state. If an additional holding torque is to

be applied after the target has been approached, the position control end time is to be

adjusted accordingly, or a holding brake is to be provided.

-2048 increments

0 increments

2048 increments

Motor axis