3 gearing compensation (l_gearcomp), Gearing compensation (l_gearcomp), Function block library lenzeelectricalshaft.lib – Lenze DDS Global Drive PLC Developer Studio User Manual

Page 26: Parameter codes of the instances

Function block library LenzeElectricalShaft.lib

Special functions

2.1.3

Gearing compensation (L_GEARCOMP)

2−16

L

LenzeElectricalShaft.lib EN 1.2

2.1.3

Gearing compensation (L_GEARCOMP)

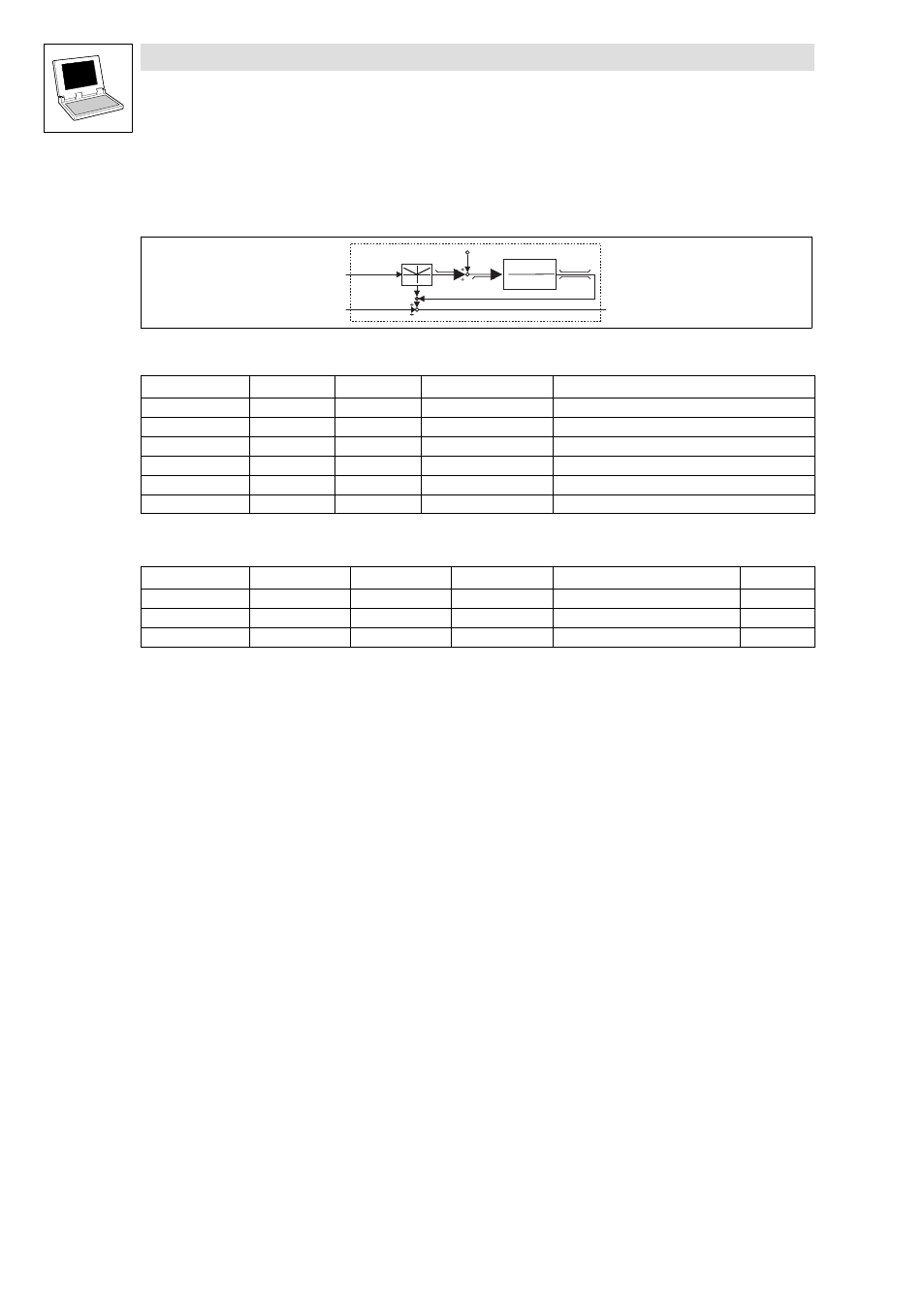

This FB compensates for elasticity in the drive chain.

L _ G E A R C O M P

d n O u t _ p

V o r z e i c h e n

n T o r q u e _ a

2

1 4

0

n O f f s e t

n N u m e r a t o r

n D e n o m i n a t o r

2

1 5

- 1

- 2

1 5

+ 1

d n P h i l n _ p

Abb. 2−9

Gearing compensation (L_GEARCOMP)

VariableName

DataType

SignalType

VariableType

Note

nTorque_a

Integer

analog

VAR_INPUT

Input value

dnPhiIn_p

Double Integer

position

VAR_INPUT

Input value

dnOut_p

Double Integer

position

VAR_OUTPUT

Initial value

nOffset

Integer

−

VAR CONSTANT RETAIN

Offset

nNumerator

Integer

−

VAR CONSTANT RETAIN

Numerator, dynamic switch−off at nNumerator = 0

nDenominator

Integer

−

VAR CONSTANT RETAIN

Denominator

Parameter codes of the instances

VariableName

L_GEARCOMP1

SettingRange

Lenze

nOffset

C1260

−16383 ... 16383

0

nNumerator

C1261

−32767 ... 32767

1

nDenominator

C1262

1 ... 32767

1

Functional sequence

1. The signal at nTorque is divided into the absolute value and the sign.

2. The value is converted (with nNumerator, nDenominator, nOffset ).

3. The result is evaluated with the sign and added to the signal at dnPhiIn_p