9 troubleshooting and fault elimination, Troubleshooting and fault elimination, Troubleshooting and fault elimination 9 – Lenze MDxMA-MHxMA-MFxMA-MDERA-MHERA Three-phase AC motors User Manual

Page 57: 9troubleshooting and fault elimination, Danger

Troubleshooting and fault elimination

9

l

57

BA 33.0005−EN 2.0

9

Troubleshooting and fault elimination

If faults occur during operation of the drive system:

ƒ

First check the possible causes of malfunction according to the following table.

)

Note!

Also observe the corresponding chapters in the operating instructions for the

other components of the drive system.

If the fault cannot be remedied using one of the listed measures, please contact the Lenze

Service.

}

Danger!

ƒ

Only work on the drive system when it is in a deenergised state!

ƒ

Hot motor surfaces of up to 140 °C. Observe cooling times!

ƒ

Remove loads acting on motors or secure loads acting on the drive!

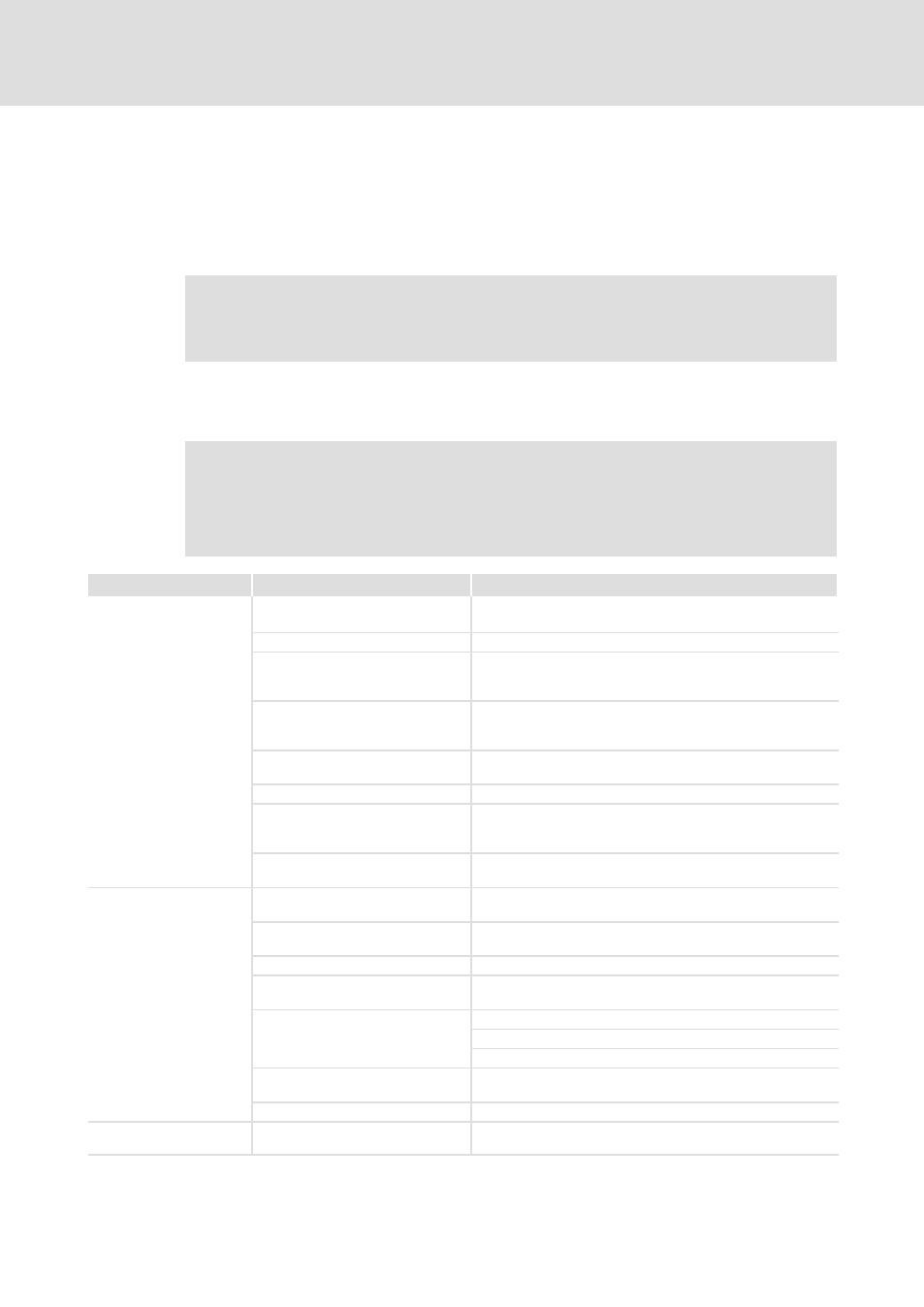

Fault

Cause

Remedy

Motor too hot

Can only be evaluated by

measuring the surface

temperature:

l

Non−ventilated motors

> 140 °C

l

Externally ventilated or

self−ventilated motors

> 110 °C

Insufficient cooling air, blocked air

ducts.

Ensure unimpeded circulation of cooling air

Preheated cooling air

Ensure a sufficient supply of fresh cooling air

Overload, with normal mains

voltage the current is too high and

the speed too low

Use larger drive (determined by power measurement)

Rated operating mode exceeded (S1

to S8 IEC/EN 60034−1)

Adjust rated operating mode to the specified operating

conditions. Determination of correct drive by expert or Lenze

customer service

Loose contact in supply cable

(temporary single−phase operation!)

Tighten loose contact

Fuse has blown (single−phasing!)

Replace fuse

Overloading of the drive

l

Check load and, if necessary, reduce by means of longer

ramp−up times

l

Check winding temperature

Heat dissipation impeded by

deposits

Clean surface and cooling ribs of the drives

Motor does not start

Voltage supply interrupted

l

Check error message on the drive controller

l

Check electrical connection

^ 32

Controller inhibited

l

Check display at drive controller

l

Check controller enable

Fuse has blown

Replace fuse

Encoder cable broken

l

Check error message at drive controller

l

Check encoder cable

Brake does not release

Check electrical connection,

^ 32

Check air gap,

^ 52

Check continuity of magnetic coil

Drive is blocked

Check components for easy movement, remove foreign

particles if necessary

Motor cable polarity is reversed

Check electrical connection,

^ 32

Motor suddenly stops and

does not start again

Overload monitoring of the inverter

responds

l

Check settings on controller

l

Reduce load by means of longer acceleration times