4 installation of a spring-applied brake, 1 brake characteristics, 2 installation of the brake – Lenze MDxMA-MHxMA-MFxMA-MDERA-MHERA Three-phase AC motors User Manual

Page 51: Installation of a spring−applied brake, Brake characteristics, Installation of the brake, Maintenance/repair, Stop

Maintenance/repair

Installation of a spring−applied brake

Brake characteristics

l

51

BA 33.0005−EN 2.0

8.4

Installation of a spring−applied brake

8.4.1

Brake characteristics

Type

s

Lürated

+0.1 mm

−0.05 mm

s

Lümax.

Service brake

s

Lümax.

Holding

brake

Max. adjustment,

permissible wear

path

Rotor thickness

Tightening

torque of the

fixing screws

[ mm ]

[ mm ]

[ mm ]

[ mm ]

min.

1)

[mm]

max. [mm]

[Nm]

BFK458−06

0.2

0.5

0.3

1.5

4.5

6.0

3.0

BFK458−08

5.5

7.0

5.9

BFK458−10

7.5

9.0

10.1

BFK458−12

0.3

0.75

0.45

2.0

8.0

10.0

10.1

BFK458−14

2.5

7.5

10.0

24.6

BFK458−16

3.5

8.0

11.5

24.6

BFK458−18

0.4

1.0

0.6

3.0

10.0

13.0

24.6

BFK458−20

4.0

12.0

16.0

48.0

BFK458−25

0.5

1.25

0.75

4.5

15.5

20.0

48.0

Tab. 2

Characteristics of the INTORQ BFK458 spring−applied brake

1)

The dimension of the friction lining allows for adjustment of the brake for at least five times.

8.4.2

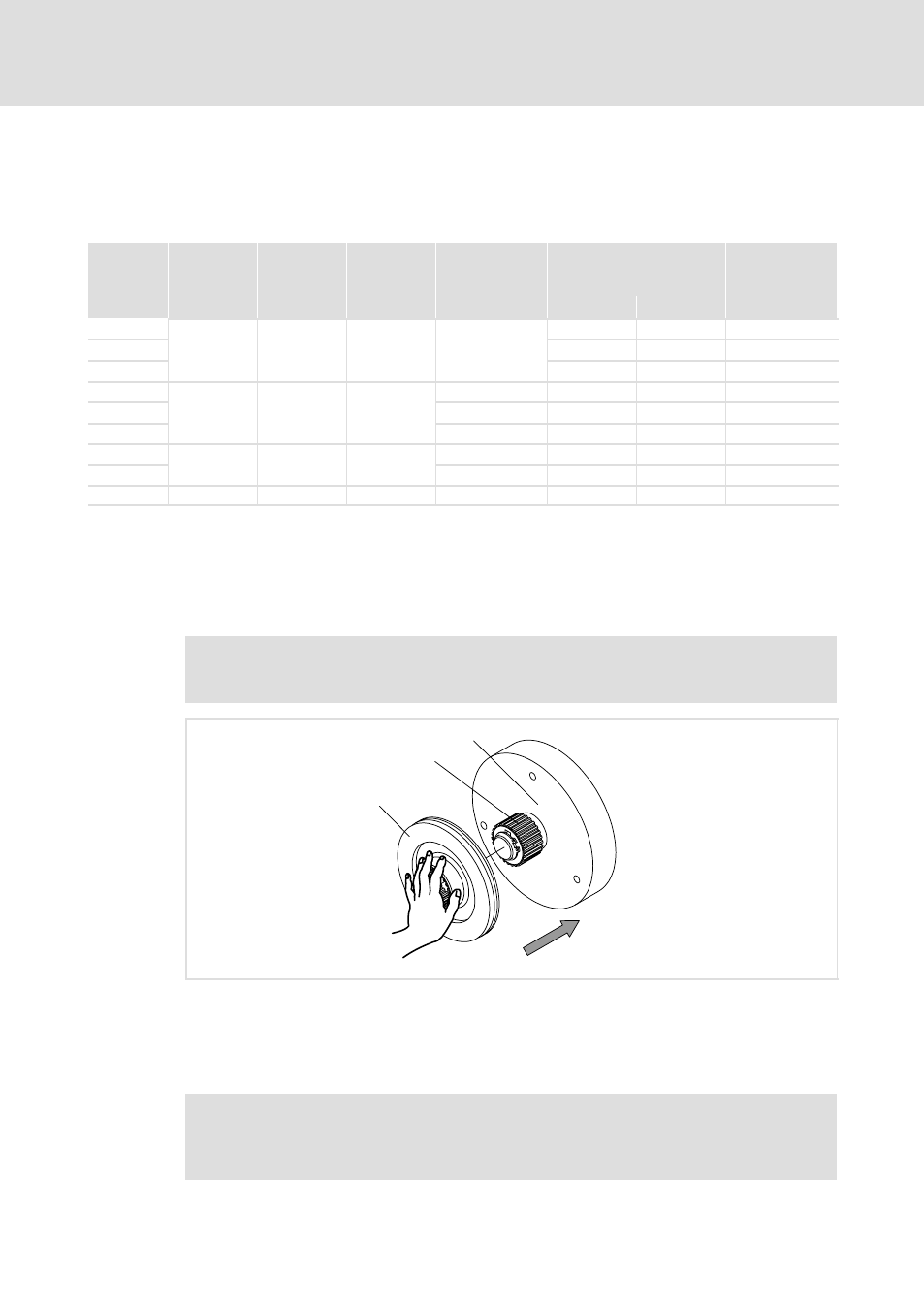

Installation of the brake

(

Stop!

ƒ

Check the state of the end shield (15). It must be free from oil and grease.

3

4

15

K14.0502/8

Fig. 3

Assembly of the rotor

3

Rotor

4

Hub

15

Endshield

1. Push the rotor (3) onto the hub (4) and check whether it can be moved by hand

(Fig. 3).

(

Stop!

Please note the following for the version "brake with shaft seal in adjuster

nut":