3 checking the component parts, 4 checking the rotor thickness, Checking the component parts – Lenze MDxMA-MHxMA-MFxMA-MDERA-MHERA Three-phase AC motors User Manual

Page 48: Checking the rotor thickness, Maintenance/repair, Stop, Danger

Maintenance/repair

Maintenance operations

Checking the component parts

l

48

BA 33.0005−EN 2.0

8.3.3

Checking the component parts

With assembled brake

l

Check function of ventilation and control

l

Measure the air gap (adjust if necessary)

l

Measure the rotor thickness (replace rotor if necessary)

l

Thermal damage to armature plate or flange (dark blue

tarnishing)

^ 49

^ 49

^ 48

After removing the brake

l

Check clearance of the rotor gearing (replace worn−out

rotors)

l

Wear of the torque bearing on threaded sleeves, dowel

pins and armature plate

l

Checking springs for damage

l

Checking armature plate and flange/endshield

– Evenness size 06...12 < 0,06 mm

– Evenness from size 14 on < 0,1 mm

– max. run−in depth = rated air gap of brake size

^ 50

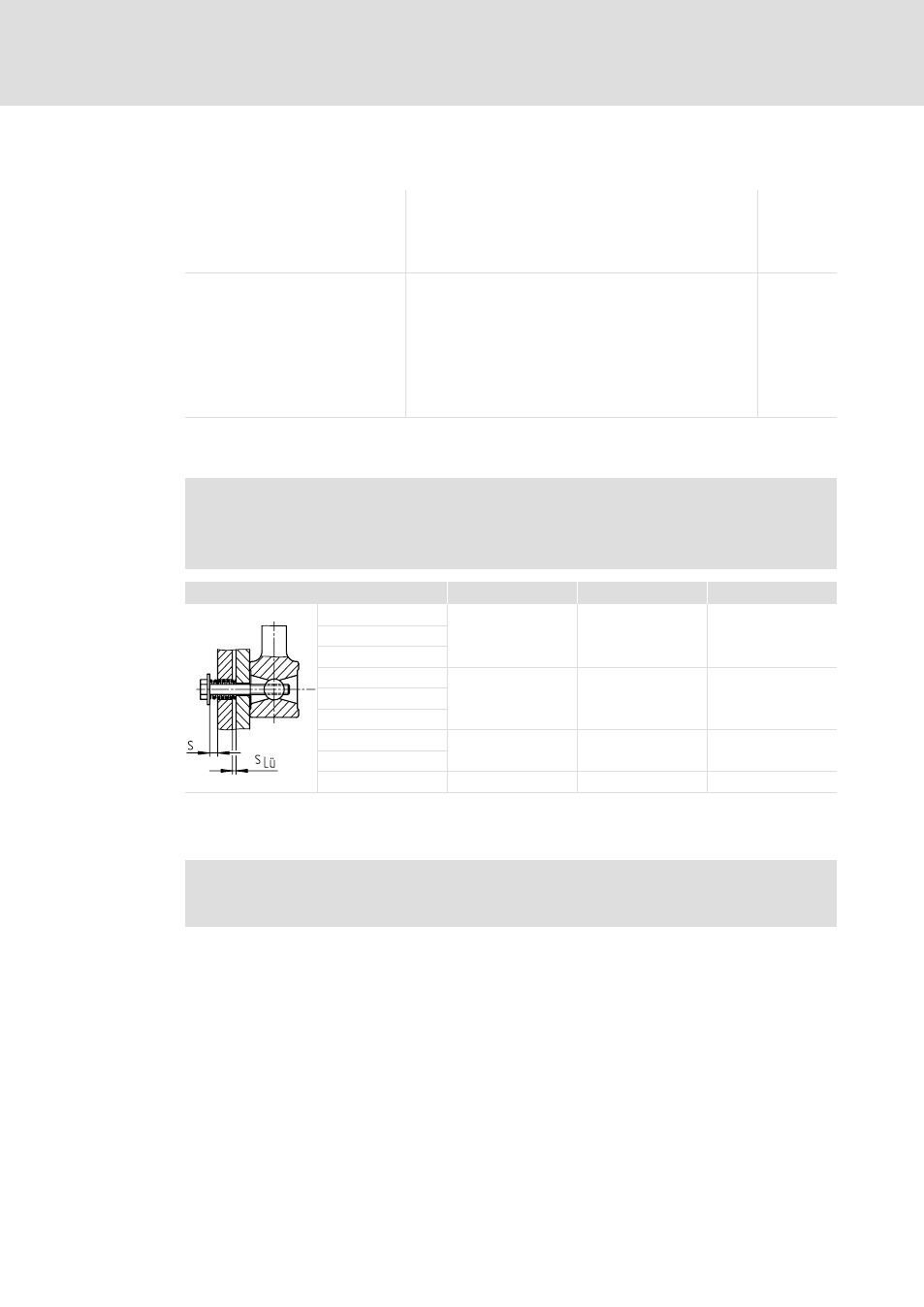

Check the mounting dimension of the manual release

(

Stop!

Dimension "s" must be maintained! Check air gap "s

Lü

"!

(

, Operating Instructions INTORQ BFK458)

Size

s

Lü

(mm)

s

+0.1

(mm)

s + s

Lü

(mm)

06

0.2

1

1.2

08

10

12

0.3

1.5

1.8

14

16

18

0.4

2

2.4

20

25

0.5

2.5

3

8.3.4

Checking the rotor thickness

}

Danger!

When the rotor thickness is checked, the motor must not run.

1. Remove fan cover and cover ring if attached.

2. Measure rotor thickness with calliper gauge. If a friction plate is attached, ensure a

flanged edge at the outer diameter of the friction plate.

3. Compare measured rotor thickness with minimally permissible rotor thickness

(values

^ 51).

4. If required, exchange the entire rotor. Description

^ 50.