Figure 4-31: hydraulic row marker adjustment, Hydraulic row marker disc adjustment (option), Caution – Landoll 5531 Grain Drill User Manual

Page 64

4-36

F-716-1213 Edition

OPERATION AND MAINTENANCE

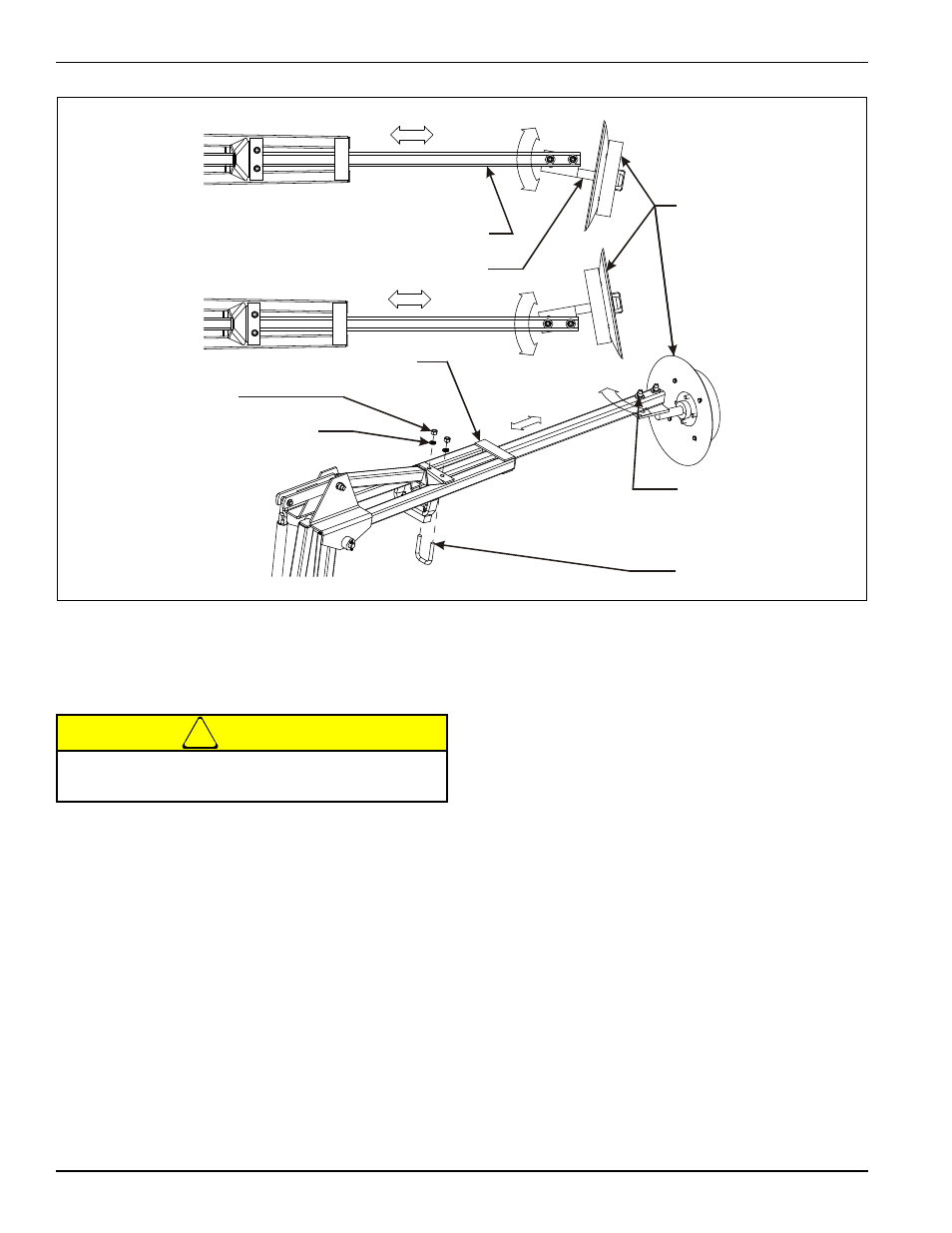

Figure 4-31: Hydraulic Row Marker Adjustment

Hydraulic Row Marker Disc

Adjustment (Option)

CAUTION

1.

The marker disc blade may be adjusted to vary the

mark left in the field.

a.

The disc angle may be adjusted to leave a wider

or narrower cut. The steeper the angle the wider

the cut will be (See Figure 4-31.)

b.

Loosen the 1/2-13 x 3-1/2” round head square

neck screws that attach the spindle assembly to

the extension tube marker weldment.

c.

Rotate the marker blade assembly as desired

and retighten the mounting bolts.

2.

The disc blade may also be configured to push or pull

soil towards the drill.

a.

To change the direction of the disc blade, first

remove the 4 bolts and dust cap retainer from

each hub assembly.

b.

Remove the two 1/2-13 x 3-1/2” round head

square neck screws that attach the spindle

assemblies to the extension tubes.

c.

Swap the spindle and hub assemblies with the

right and left markers.

d.

Using the 1/2-13 x 3-1/2” round head square

neck screws, attach the spindle assemblies to

the bottom of the extension tubes.

e.

Change the direction of the marker disc blade

and reinstall the 4 mounting bolts and dust cap

retainer.

3.

To adjust the cutting width of the marker disc, loosen

the u-bolt that secures the extension tube to the

outer arm assembly.

4.

Slide the extension tube in or out to the desired

position and retighten the u-bolt.

5.

Pull the drill a short distance and verify adjustment.

row marker adjustment

EXTENSION TUBE

MARKER WELDMENT

SPINDLE ASSEMBLY

MARKER BLADE

ASSEMBLY

1/2-13 X 3-1/2 RD

HEAD SQ NECK

SCREW AND HEX

LOCK NUT

U-BOLT

OUTER ARM ROW MARKER WELDMENT

1/2-13 HEX NUT

1/2 SPLIT LOCK WASHER

Marker blades are very sharp. Use gloves when

working around marker blades.