Air system pressure, Figure 4-7: air system pressure – Landoll 5531 Grain Drill User Manual

Page 39

OPERATION AND MAINTENANCE

4-11

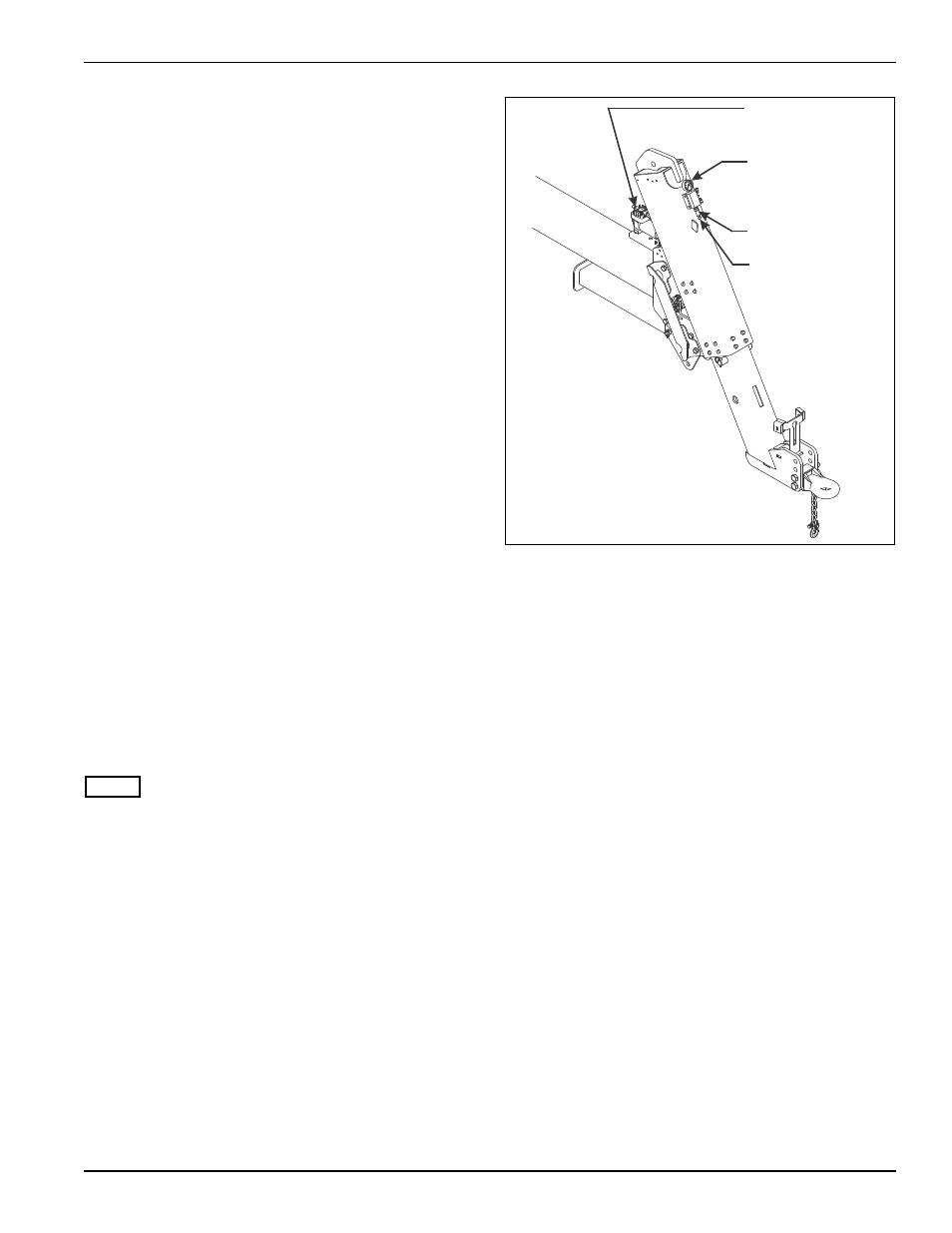

Air System Pressure

1.

The air system pressure on the Grain Drill can safely

operate in a range from 15 psi to 100 psi. A system

pressure gauge is located at the front of the hitch and

can be seen from the tractor to monitor system

pressure (See Figure 4-7.) It is normal for the

system air pressure to vary while working in the field.

As the openers raise and lower over ground

conditions, so will the system pressure vary.

2.

Do not at any time operate the air system below 15

psi. The air springs must maintain a minimum air

pressure for proper inflation. Too low of pressure will

cause the air spring to rub internally and lead to

failure.

3.

System pressure should not exceed 100 psi. This is

the maximum recommended working pressure the

air springs are rated for. This will provide maximum

down pressure for the row units. A system relief valve

is installed at the front of the hitch to protect the

system from excessive pressure. Do not remove or

adjust the relief valve or damage to the air system

may occur.

4.

To adjust the air system pressure, use the on board

air compressor to increase system pressure (See

“Compressor Operation” on page 4-10.) To lower

system pressure, pull and hold the ring located at the

bottom of the relief valve on the front of the hitch.

5.

Initial settings – When beginning planting operations,

use a system pressure of 20-50 psi for light or sandy

soils, 40-60 psi for medium or conventional tilled

soils, and 70-100 psi for heavy and no-till planting.

These are initial settings. Operator must verify seed

placement and adjust air system pressure as

required.

NOTE

Excessive air pressure can raise the drill out of the

ground, particularly with low seed levels in the seed box.

Figure 4-7: Air System Pressure

6.

Maintenance – Relieve air system pressure before

attempting to adjust or service any air spring. Do not

pressurize the air system unless all row unit

components are in place. When charging the system,

verify that all air springs are filling properly. If the air

spring buckles or rolls off to the side, relieve system

pressure, and work or roll the air spring over the

lower piston by hand. Slowly begin charging the

system and verify proper filling.

7.

Storage – When storing the drill, leave the air system

charged, and allow the system to slowly leak down.

AIR

COMPRESSOR

0-160 PSI

PRESSURE

GAUGE

RELIEF VALVE

RELIEF VALVE

RING

5531 air system pressure op