Figure 4-22: air spring adjustment, Air spring adjustment, Caution – Landoll 5531 Grain Drill User Manual

Page 55

OPERATION AND MAINTENANCE

4-27

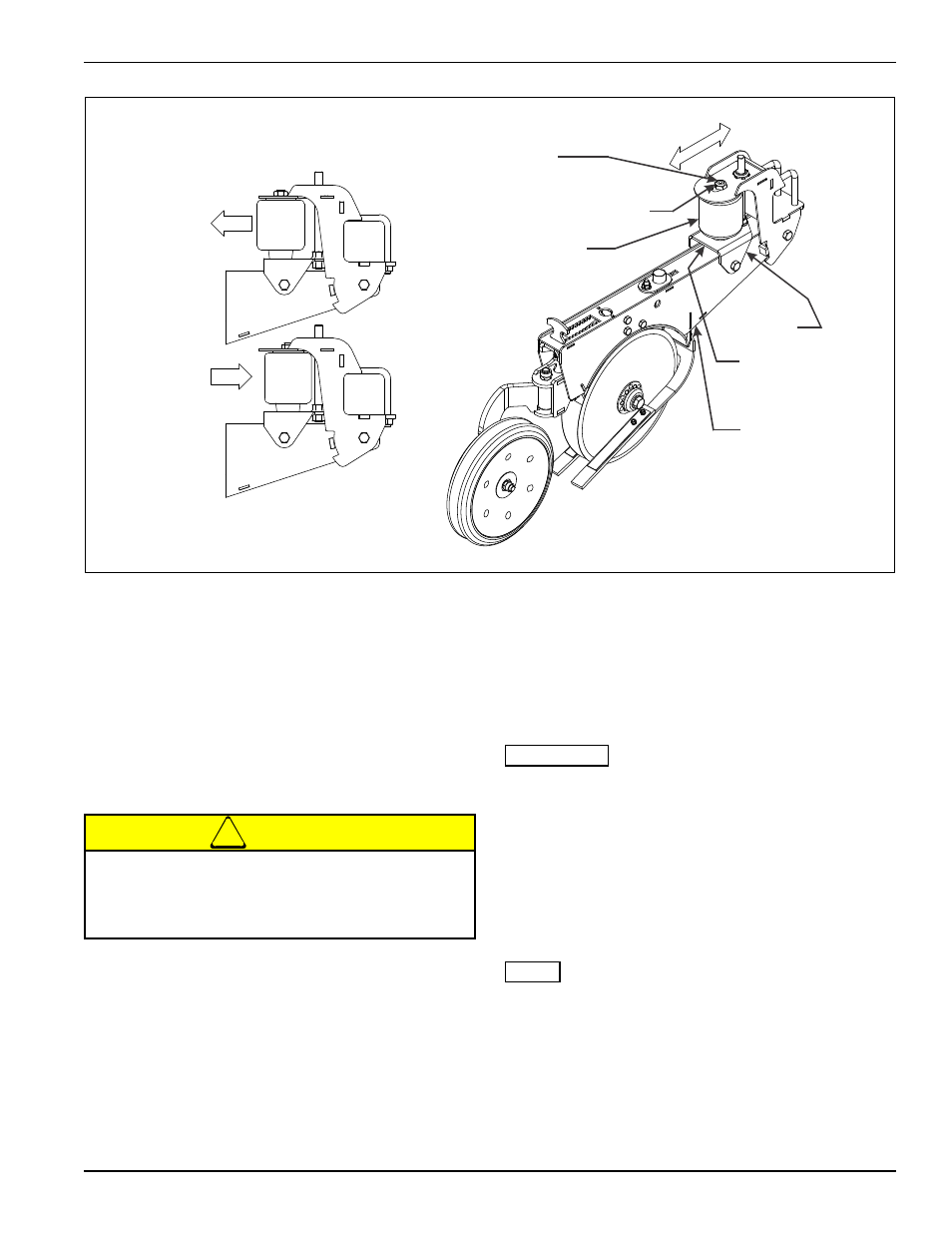

Figure 4-22: Air Spring Adjustment

Air Spring Adjustment

1.

The air pressure delivered to the air springs is the

same for all openers. To be able to increase the

down pressure for specific row units such as in wheel

track locations, the air spring has two mounting

positions. The normal position is forward, with a

heavier setting by sliding the air spring to the rear.

The heavier setting will increase the down pressure

by approximately ten percent.

CAUTION

2.

To adjust the air spring location, first relieve the

system air pressure. Loosen, but do not remove the

3/4-16 hex jam nut at the top of the air spring and the

1/2-13 x 1 hex head cap screw below the air spring

and air spring pivot. Slide the air spring forward or

rearward to the desired location (See Figure 4-22.)

IMPORTANT

Make sure the air spring has fully reached the ends

of the top and bottom slots before retightening. If the

air spring is not in the ends of the slot, it will be out

of alignment and can rub internally wearing a hole.

Also, be sure the air spring is not twisted when

retightening the fasteners.

3.

Retighten the top jam nut and bottom hex head cap

screw to secure the air spring. Recharge the system

with air to normal working pressure.

NOTE

Maximum torque on the top jam nut is 30 ft. lbs.

air spring adjustment

3/4-16 HEX JAM NUT

AIR SPRING

AIR

SPRING

PIVOT

1/2-13 X 1

HEX HEAD

CAP SCREW

AIR OPENER

ASSEMBLY

HEAVY

SETTING

NORMAL

SETTING

NOTE:

MAXIMUM TORQUE

30 FT. LBS.

Relieve system air pressure before attempting to

adjust or service any air spring component.

Make sure all components are in place and

secure before charging the system.