Fasteners, Lubrication, Caution – Landoll HCDA73-1 Soil Builder Coulter Chisel User Manual

Page 35

MAINTENANCE

4-3

Fasteners

Before operating your Brillion machine, check all

hardware for tightness. Use the Tightening Torque Table

as a guide. See Page 4-1.

After a few hours of use, check entire machine and

tighten any loose nuts or bolts. Daily or periodic checks

should be made thereafter.

When replacing bolts, be sure to use fasteners of equal

grade.

Lubrication

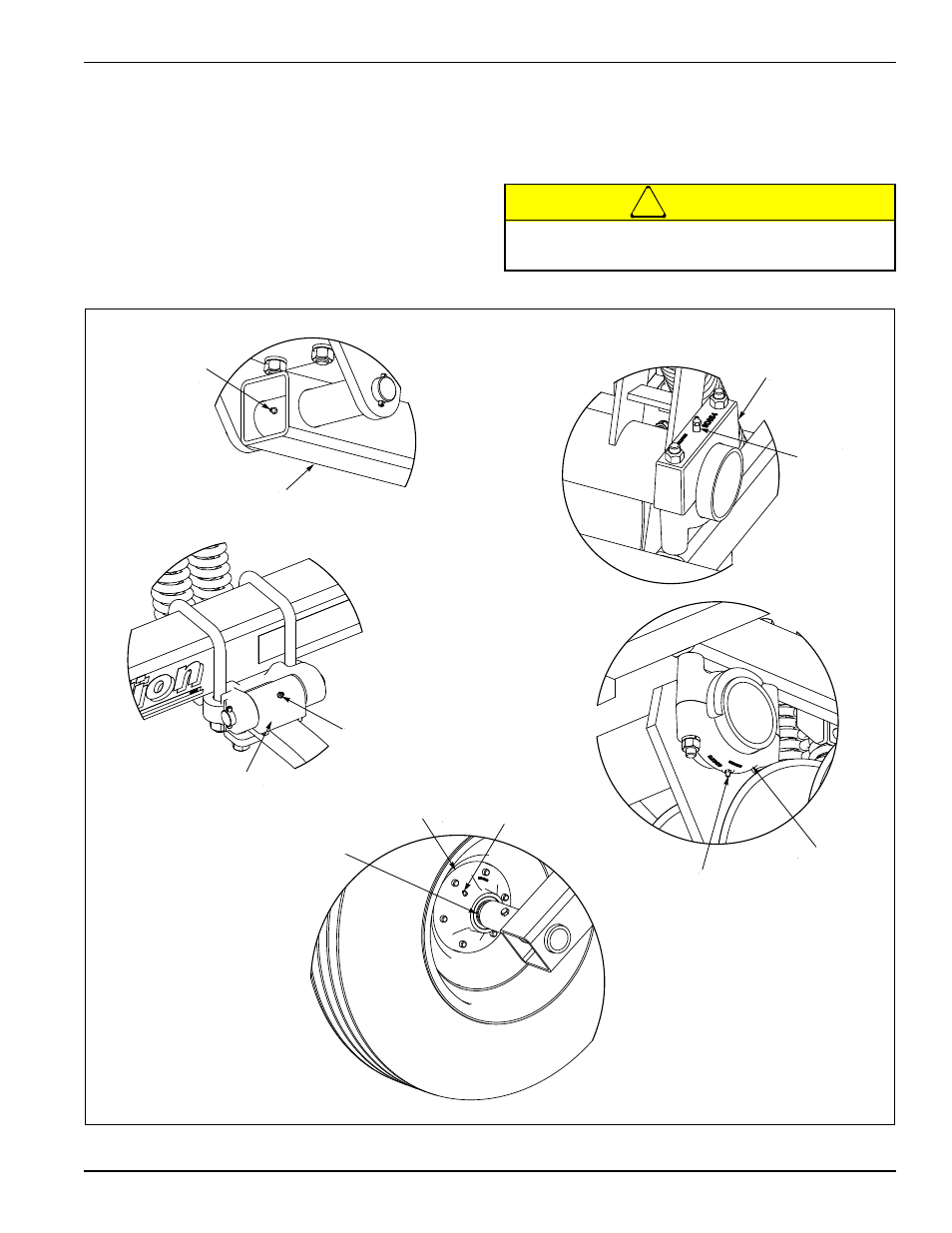

Lubricate with quality grease per recommended

lubrication frequency intervals indicated or if machine is

not used for an extended period. See Figure 4-1.

CAUTION

Figure 4-1: Lubrication Points and Intervals

Over lubrication of these bearings can cause

premature bearing failure.

WHEEL

HUB

Grease

80-100 Hrs

Repack

Annually

GAGE WHEEL

ARM ASSEMBLY

Grease

Daily

SHANK

HOLDER

Grease

Daily

AXLE

BEARING

Grease

Daily

HEAVY AXLE

BEARING

Grease

Daily

OpCD SoilBuild Lube