KD Scientific Allegro Peristaltic Pump Series User Manual

Page 10

10

K

D

S

A

lle

g

ro

P

e

ri

s

ta

lt

ic

P

u

m

p

S

y

s

te

m

U

s

e

r’s

M

a

n

u

a

l

phone

508.429.6809

fax

508.893.0160

web

www.kdscientific.com

Product Over view

KD Scientific Allegro Peristaltic Pump System User’s Manual

Publication 5617-006 Rev E

Product Overview

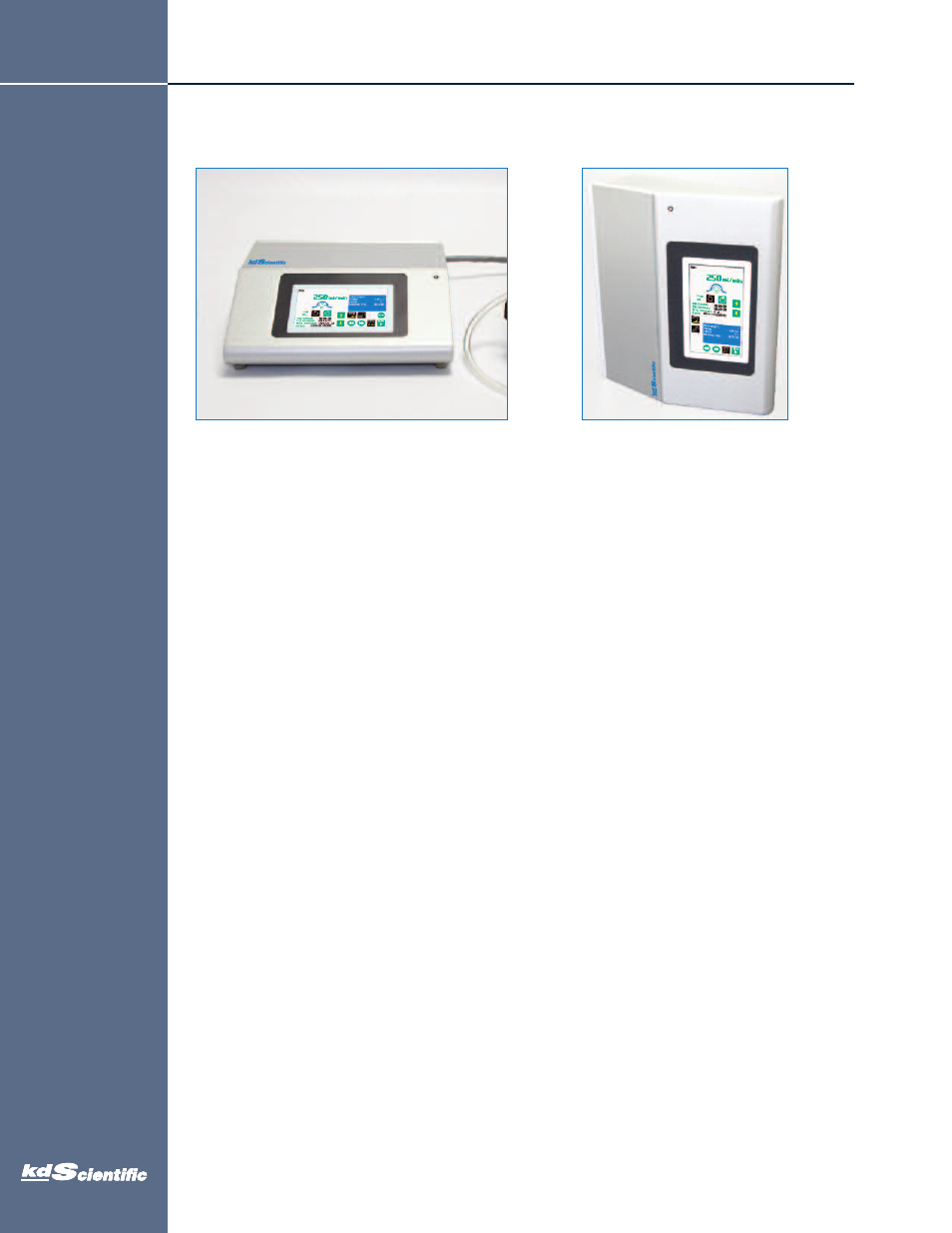

The KD Scientific Allegro Peristaltic Pump System is

the next generation of peristaltic pumps. The system

offers unparalleled ease of use through the high

resolution color touch screen user interface. The full

touch screen interface enables the user to quickly create

configurations and recall them for easy use. The TFT

color display presents all the pump operating parameters

on an easy to view run screen.

The password feature prevents accidental configuration

changes ensuring the program’s integrity is retained.

Programs can also be set to be started on a time delay

for unattended operation.

An led light on the front panel makes it easy to see if the

pump is running. Once the pump starts to run, the display

shows the pump is running and the LED turns on. This will

make it easy to see the pump’s status.

The pumps are versatile and can be interconnected through

the RS-485 interface. Allegro Peristaltic Pump System

models can be mixed and matched in the daisy chain

offering maximum flexibility. Up to 99 pumps can be linked

together through the RS-485 interface. This interface is easy

to use provided each pump is assigned its own unique

pump address.

For limited laboratory space the Allegro Peristaltic Pump

controller can be placed on its side to reduce the

footprint. The display also tilts with the change to allow

the user to operate the pump vertically. The pump heads

can be stacked to save bench space.

Notifications and error messages are displayed for the

user to acknowledge, eliminating any guesswork about

problems.

Flow performance is optimized with a small step angle

stepping motor. The tubing mechanism is easy to use and

securely holds the tubing for smooth flow performance.

Advanced microstepping techniques are employed to

further reduce the step angle to eliminate flow pulsation.

A wide dynamic flow range can be programmed into the

pump. Flow rates are selectable with user selected

engineering units from L, ml, µl, nl and hours, minutes

and seconds.

The superior design of the full metal chassis provides

noise isolation and anti-vibration features for increased

reliability.