Fence bridge adjustment, Incra stop, In-line fence applications – INCRA Intelli-Fence User Manual

Page 6: Vertical panel raising, Safety

SAFETY

FIG. 12

Vertical panel raising

Adjust infeed/outfeed fences to the

in-line/mid-range position as

described on page 5.

Use a straight edge to adjust the

Hi-Rise fence cap in line with the

infeed and outfeed fences. (See Fig. 1A

on page 2.)

Remember: Do not make the full

width of the cut in a single pass.

Instead, use several light side-by-side

passes, moving the fence back

1

⁄

16

" or

so after each pass.

5

3

4

6

IN-LINE FENCE APPLICATIONS

Once set to the in-line/mid-range

position as described on page 5, your

new INCRA Intelli-Fence can be used

for a variety of typical in-line fence

applications, including grooving,

dadoing, and edge forming operations

such as rabbeting, chamfering, and

roundovers. You’ll also find the in-line

position useful for many specialty

operations. With the Hi-Rise fence cap,

you’ll be able to use vertical panel

raising bits to make raised panels for

cabinetry, and since its design is

compatible with all INCRA joint-making

accessories, you’ll be able to use the

Intelli-Fence in conjunction with

your INCRA Jig Ultra or Pro as a

joint-making fence.

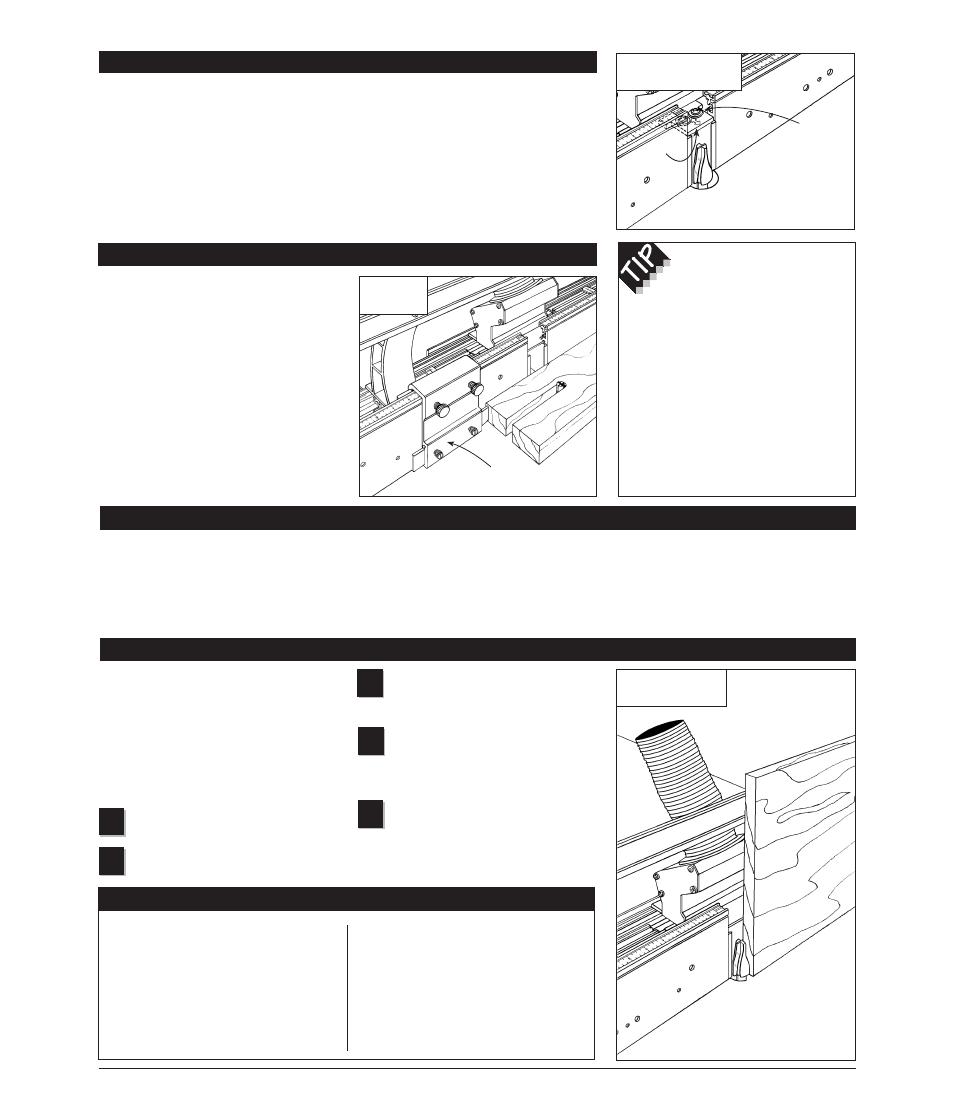

Vertical Panel Raising

The introduction of the vertical panel

raising bit has made cutting the reveal on

a raised panel a relatively simple

operation for the router table. You’ll find

your new Intelli-Fence, with its built-in

dust collection, adjustable fence gap,

and Hi-Rise fence cap, perfect for this

operation. The setup is as follows, Fig 12:

Install vertical panel raising bit and

set appropriate depth of cut.

Adjust fence gap as necessary

(see Gap Adjustment on page 5).

1

2

❒

Whenever using large diameter

vertical or horizontal panel

raising bits or any other large

diameter bit, always follow

that router bit manufacturer’s

operation and safety

recommendations.

❒

Whenever it is necessary to

remove large amounts of

stock, always use multiple

side-by-side passes to achieve

the final cut. Several shallow

cuts are safer and will yield

better results.

FIG. 11

INCRA Stop

When used in conjunction with your new

INCRA Intelli-Fence, the INCRA Stop

provides the same precise rack positioning

capabilities that made the INCRA Jig

famous. The sliding scale in the top of the

fence becomes a versatile reference for use

in setting stop positions at the router table.

The adjustable plastic stop permits micro

adjusting of the stop positions anywhere

between the

1

⁄

32

" tooth spacing on the

INCRA racks. The bi-directional design

allows the INCRA Stop to function on the

infeed or outfeed end of the fence with any

thickness of stock.

INCRA STOP

INCRA Stop

INCRA Stop

The fence bridge can be

mounted with either the narrow

or wide end in the opening

between the infeed and outfeed

fences. With the narrow end forward

the fence opening will be

5

⁄

8

". This

opening is great for smaller joint

making bits like the

1

⁄

4

" and

3

⁄

8

"

straight or the

1

⁄

4

",

5

⁄

16

", and

3

⁄

8

"

dovetails. With the wider end of the

fence bridge forward the opening is

increased to 1

1

⁄

8

", perfect for use

with larger dovetail bits.

FIG. 10

Fence bridge adjustment

The adjustable fence bridge is used during

joint making to provide support for narrow

vertically held stock as it is moved past the

opening between the infeed and outfeed

fences. For all other cutting operations the

fence bridge can be positioned behind the

front face of the Intelli-Fence and tightened

in place. For use during joint making, first

return the fences to the in-line/mid-range

position described above. Loosen the

screws that secure the fence bridge and

slide it forward into the opening between

the fences. Adjust the fence gap as

described on page 5 to close the fence

ends on the bridge. Now use a straight

edge to locate the fence bridge flush with

the front face of the fence and tighten the

mounting screws. See Fig 10.

Fence Bridge Adjustment

Loosen

mounting screws

and slide fence

bridge forward for joint

making applications

Use straight edge to align fence

bridge flush with fences

Fence

bridge