INCRA Miter Express User Manual

Page 4

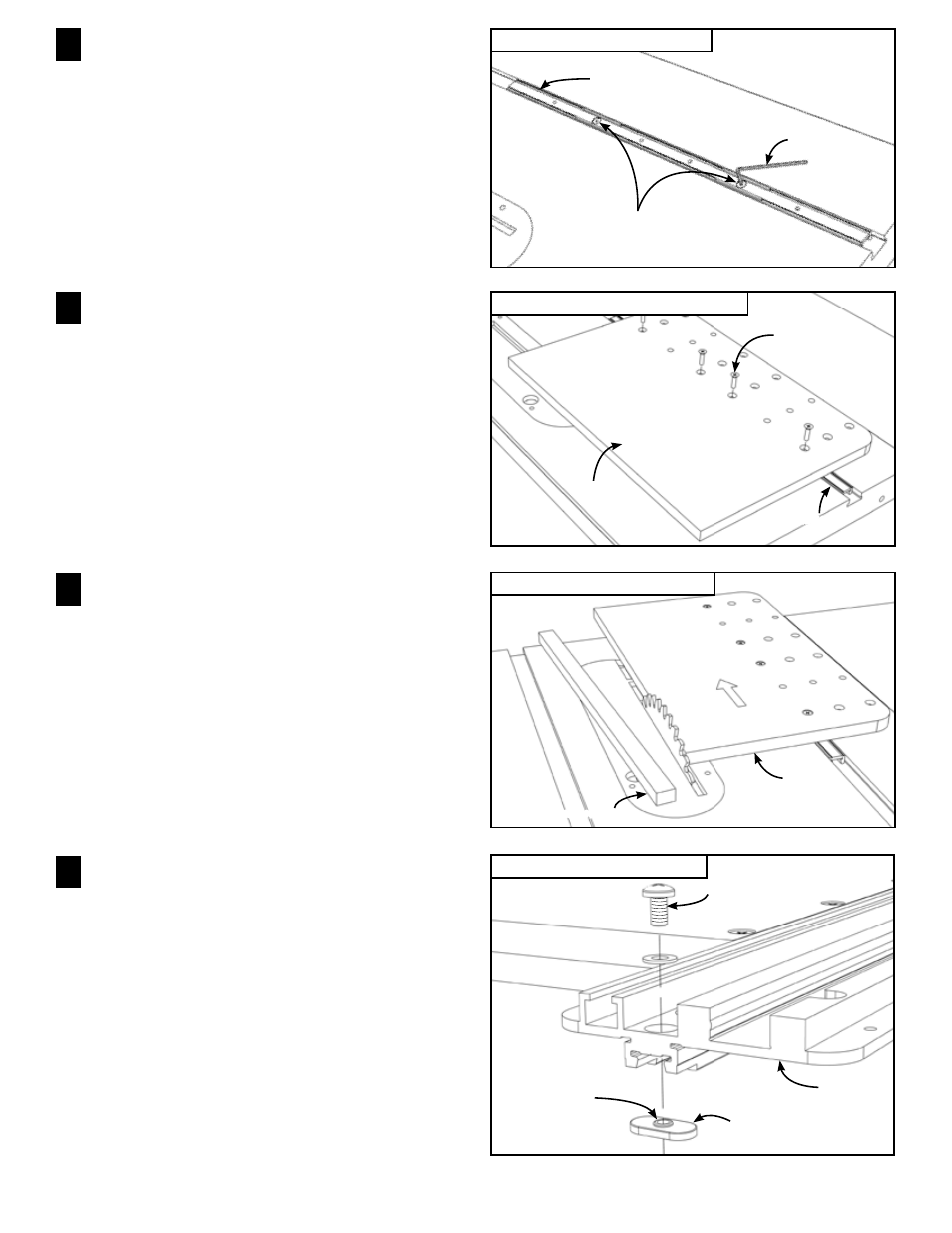

FIG. 10

Attach T‑slot retainers

FIG. 8

Attach drop panel to miter bar

FIG. 9

Cut off drop panel overhang

Attach Drop Panel to Aluminum Miter Bar

Using (4) #10-24 x ¾” Phillips flat head screws,

attach the drop panel to the aluminum miter bar. Use

the mounting holes that permit the least amount of panel

overhang beyond the line of cut, Fig. 8.

6

Cut Off Drop Panel Overhang

Raise the saw blade about ¾” and make a cut to

remove the portion of the drop panel that extends beyond

the line of cut, Fig. 9. Turn off the saw, lower the blade

and return the Utility Plate assembly to the table saw.

CAUTION: In use, only the Utility Plate assembly

slides to move your workpiece through a cut. The

drop panel will be positioned adjacent to the blade

and locked in place by tightening the (2) expansion

mechanisms to provide zero clearance and workpiece

cutoff support. (See Fig. 12)

7

Attach T-Slot Retainers

Note: Skip this step for non T-slot miter channels.

Open Hardware Pack C-14. Slide the Utility Plate panel

assembly to overhang the edge of your table saw and

attach the T-slot retainer using the #10-32 x

3

/

8

” Phillips

pan head screw as shown in Fig. 10.

The raised rim around the T-slot retainer’s threaded hole

should face upward. Repeat for the opposite end of the

Utility Plate.

8

4

FIG. 7

Adjust aluminum miter bar

Adjust Aluminum Miter Bar

Using the supplied

3

/

3 2

” hex key, adjust the aluminum

miter bar at each of the (2) expansion mechanism

locations for a good sliding fit in your table saw’s remaining

miter slot. Turning the screw clockwise expands the

mechanism. Expand a little at each of the locations until

the bar slides smoothly with no side play, Fig. 7.

5

Expansion

mechanisms

3

/

32

” Hex key

Aluminum miter bar

Drop panel

#10-24 x ¾”

Phillips flat head

screws

Miter bar

Drop panel overhang

Drop panel

#10-32 x ³/₈” Phillips pan head screw

Utility plate

T-Slot retainer

Raised rim face up