5troubleshooting, Led legend – Hydrolevel 3100 User Manual

Page 5

5

TROUBLESHOOTING

Burner Will Not Fire

See Flow Chart 1, page 6

Burner Will Not Shut Down

See Flow Chart 2, page 7

Temperature Display Exceeds

High Limit Setting

Under normal operation, boiler temperature will continue to rise after the control shuts off

the burner. This condition, known as “thermal stacking”, results from hot boiler surfaces

continuing to release heat into the boiler water.

Red Light on Circuit Board

is Flashing

The red light to the left of the temperature display will flash if the transformer has been

overloaded. (See top portion of troubleshooting flow chart on page 6.)

No Domestic Hot Water

If the boiler is equipped with a tankless coil, make sure the low limit setting on the

HydroStat is set properly. NOTE: If the low limit setting is dialed fully counter clockwise, it

will shut off the low temperature maintenance feature.

Boiler Will Not Maintain

Low Limit Temperature

Check for overlapping high temperature setting. If the high limit setting is set below the

low limit setting, the control will default to the high limit setting and the corresponding

high limit differential setting.

Temperature Display

Differs from Boiler

T&P Gauge Temperature

Reading

Temperature variances can result from differing water temperatures within the boiler or

different reaction times of the two devices. If the HydroStat temperature is significantly

below the T&P gauge temperature, make sure the thermistor is inserted all the way to

the end of the well. If installed in an existing conventional well, check that hardened heat

conducting grease has not impeded the insertion of the thermistor. Clean or replace the

well to ensure proper insertion of the sensor.

LWCO “Active” Light

(Green LED) Is Not On

When Installed on Standard Immersion Well: This is a normal condition. The control

will provide temperature functionality only. The HydroStat must be installed on a

Hydrolevel Electro-Well for low water cut-off functionality.

When Installed on a Hydrolevel Electro-Well: The control is detecting unusually high

conductivity. Check for minimum ½" clearance between the copper well tube and any

surface within the boiler.

Low Water Light

(Red LED) Is On

WARNING: A low water condition is a serious and potentially dangerous condition. Do

not attempt to add water to a hot boiler. Allow the boiler to fully cool before adding water.

1. If the heating system is filled with water, pull the sensor out of the well and inspect it.

Make sure that the metal clip on the sensor is intact. This metal clip must be in contact

with the inside of the copper well in order for the control to sense the presence of

water. Check that the well does not have excessive build-up of heat transfer grease

that may interfere with clip contacting the well.

2. Remove well and examine for excessive residue build-up. Clean and re-install.

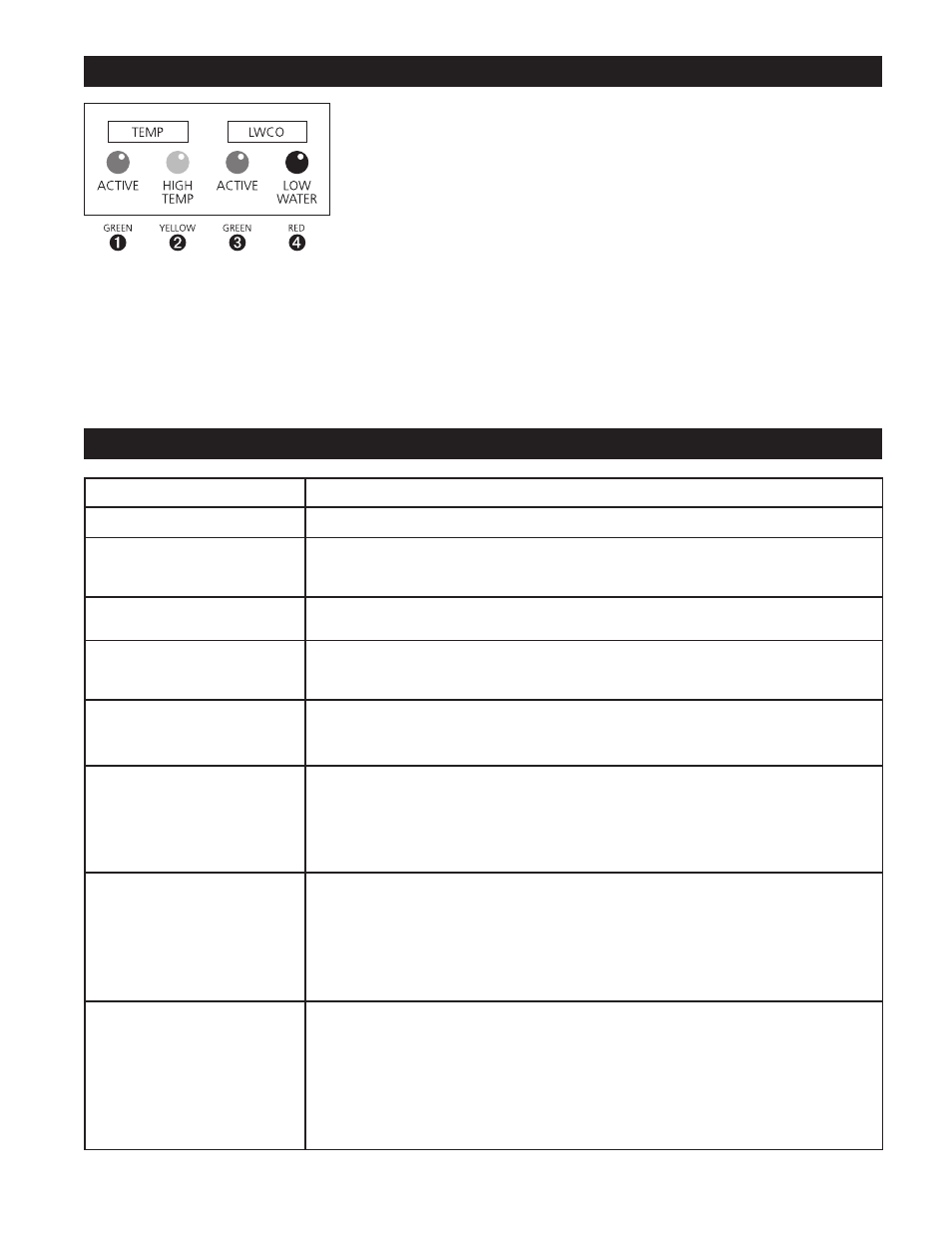

LED LEGEND

ᕡ

TEMP ACTIVE

Indicates that

the HydroStat control is powered and

that the temperature function is active.

ᕢ

TEMP HIGH TEMP

Illuminates

when the boiler water temperature

reaches the high limit setting. It will

remain lit until the water temperature

falls below the high limit setting less

the differential setting. The HydroStat

control will prevent burner operation

while this LED is on.

NOTE: This LED illuminates regularly

during normal boiler operation.

ᕣ

LWCO ACTIVE

Indicates that

the low water cut-off (LWCO) function

of the HydroStat control is active.

When the control is installed with a

Hydrolevel Electro-Well, this LED will

be on at all times when the control is

powered.

NOTE: If the control was installed with

a well other than the Electro-Well, this

LED will not illuminate. This indicates

that the control is providing

temperature function only.

ᕤ

LWCO LOW WATER

Indicates

that the boiler is in a low water

condition. The HydroStat control will

prevent burner operation during this

condition.

IMPORTANT:

The system must be checked by a

qualified heating professional prior to

resuming operation.

WARNING: ALLOW THE BOILER TO

FULLY COOL BEFORE ADDING

WATER.