Hydrolevel 724 Series User Manual

Low water cut-off feeder combination, How to install

724 Series

Low Water Cut-Off

Feeder Combination

for Steam Boilers

24 VAC Operating Voltage

HOW TO INSTALL

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 •

www.hydrolevel.com

No moving parts in water.

No floats to hang-up or foul.

Unique two probe design. Bouncing

water line wonʼt cause on-off burner

cycling or water valve slamming

noise.

Easy installation. Quick hook-up

fittings adapt control to all 8" to 14"

sight glasses.

Simple fast wiring. Can be used with

any standard automatic water feeder.

WARNING: Power must be off during installation or servicing of the control. Only qualified personnel may install or service the

control in accordance with local codes and ordinances. Read instructions completely before proceeding. Caution – Disconnect power

supply before beginning installation to prevent electrical shock or equipment damage.

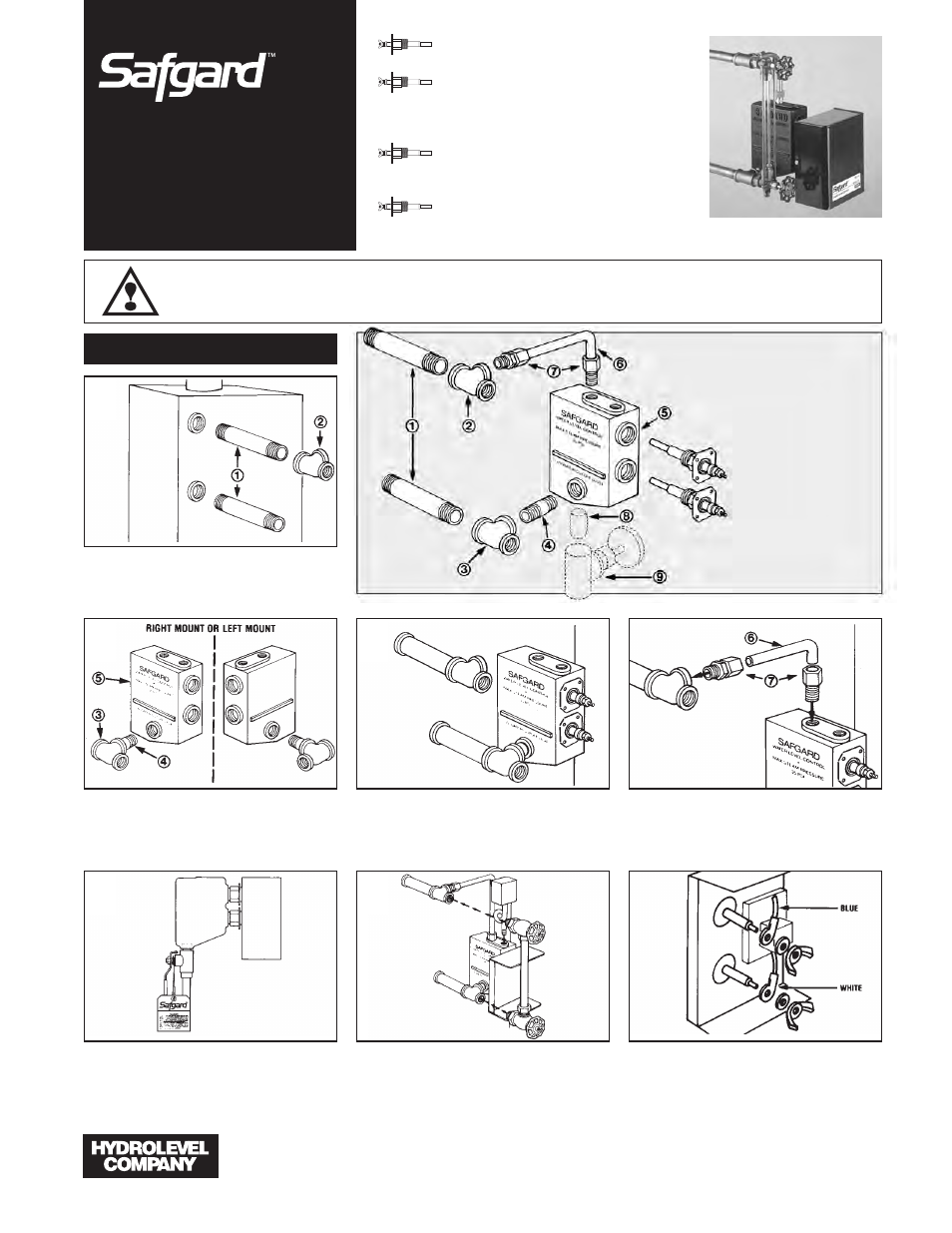

Remove gauge glass assembly and nipples replac-

ing nipples with two 6" brass nipples provided

.

Install 1/2" x 1/2" x 3/8" tee

on top nipple.

Install 1/2" x 2" brass nipple

and 1/2" x 1/2" x

1/2" tee

to 1/2" threaded hole in casting

.

Note: Casting is designed for either left or right

mounting on gauge glass. Be sure to plug hole on

opposite side.

Thread tee attached to casting into bottom 6" nip-

ple. Tighten until casting is vertical.

Install compression fittings

into casting and

top tee. Size copper tubing

and tighten

between the two compression fittings.

Attach control to probes using No. 8-32 self tap-

ping screws provided. Install blow down valve (by

others) in bottom 3/4" tapped hole. Be sure to

attach maintenance tag in prominent place near

valve.

Reattach gauge glass cocks and gauge glass into

end of 1/2" tees. Pressure-trol can be threaded

into 1/8" threaded hole on top of casting. If pres-

sure-trol is not used, plug 1/8" hole on top of

casting.

Attach blue probe lead wire to upper probe and

white probe lead wire to bottom probe with wing

nuts and lock washers provided.

(2) 6" x 1/2" brass nipples

(1) 1/2" x 1/2" x 3/8" tee

(1) 1/2" x 1/2" x 1/2" tee

(1) 2" x 1/2" brass nipple

(1) 711C manifold casting

(1) 3/8" copper tube

(2) 3/8" compression fittings

(1) 3/4" nipple (not included)

(1) Blow down valve

(not included)

1

2

3

4

5

6

7