Flint & Walling Commander Pro 300 User Manual

Page 9

9

95 North Oak Street • Kendallville, IN 46755

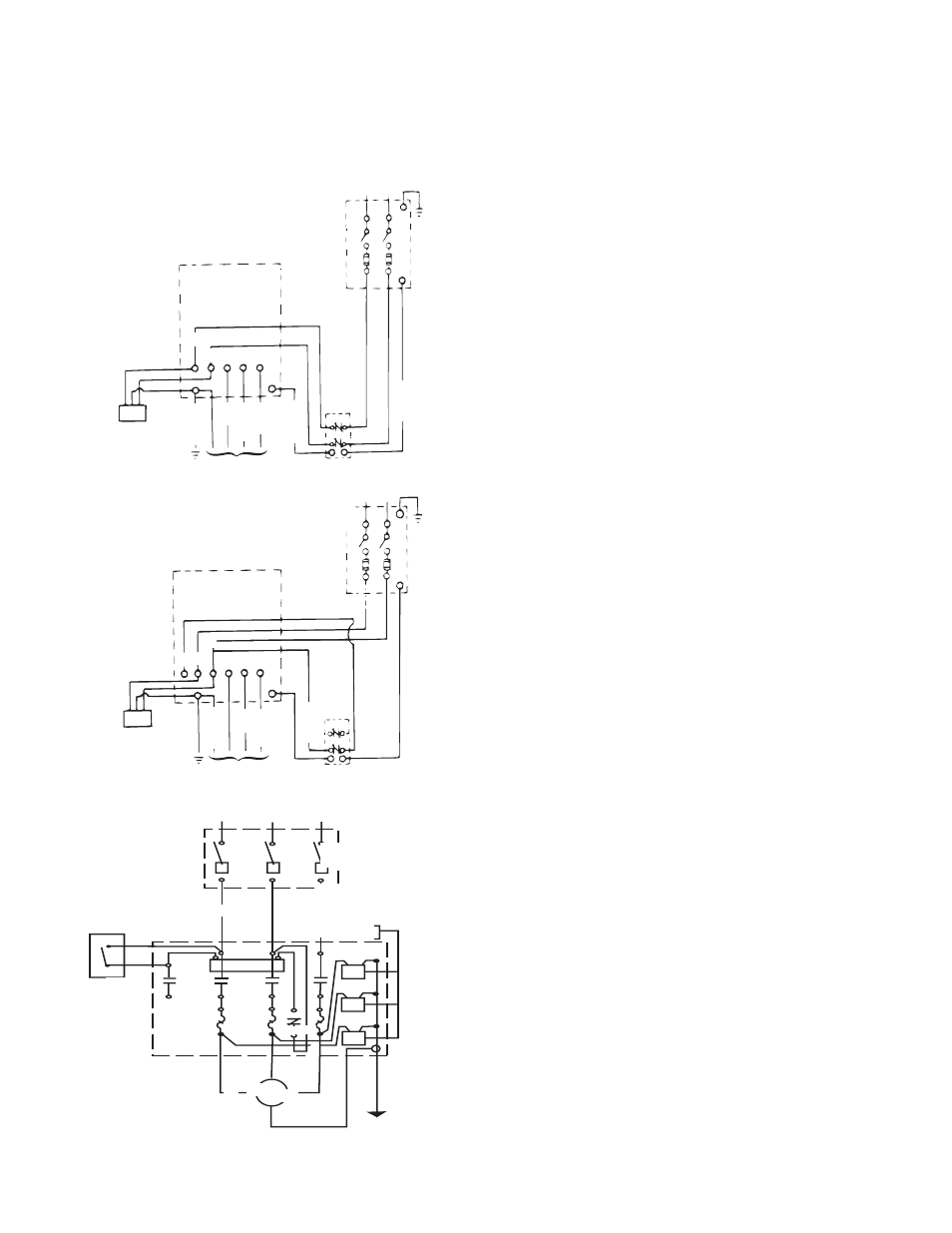

1. Proceed with electrical hook-up matching cable

colors and following the wiring diagrams (Figures

9, 10 &11) or inside the lid of the control box.

WARNING: Connect motor leads momentarily for

correct rotation before installing pump in well.

FUSE SIZES

IL0100

Figure 9 — Single Phase Control Box

Fused Disconnect

Switch

Ground

Pressure

Switch

Ground

L1

L2 R Y B

Control Box

Lightening

Arrestor

To Motor

Ground

Red

Yellow

Black

IL0101

Figure 10 —

Single Phase Control Box with Contactor

SW

L1

L2 R Y B

Lightening

Arrestor

To Motor

Pressure Switch

Control Box

Fused Disconnect

Switch

Ground

Ground

Ground

Red

Yellow

Black

IL0102

Figure 11 — Three Phase Magnetic Starter

Fused Disconnect

Switch

Lightening Arrestors

Pressure

Switch

Motor

Ground

L3

L2

2

3

T1

T2

T1

T2

T3

V

M

1

L1

X2

W

T3

1. For proper sizing of fuses for fuse disconnect

box, see Motor Data Charts. Improperly sized

fuses will result in fuses blown or circuit breakers

tripped.

GROUNDING

Proper Grounding of Submersible Motors

1. The purpose of grounding any electrical

apparatus is to prevent an electrical shock hazard

if exposed metal becomes connected to an

electrical circuit. This can occur from a defect in

construction of the electrical equipment, physical

damage, or a breakdown in the insulation of the

equipment. Grounding prevents shock hazard by

keeping exposed metal from reaching a voltage

level which could endanger anyone coming in

contact with the electrical equipment. Fault

current is “drained” by the ground conductor, and

if the fault is severe enough, the circuit will be

opened by the fuse or circuit breaker.

2. The U.S. National Electrical Code (NEC) requires

that motor-operated water pumps, including

submersible type regardless of voltage, shall

be grounded. The Canadian Electrical Code

specifically discusses grounding requirements

for submersible pumps. Interpretation of these

and other codes may vary in different states and

localities, but all applicable national, state, and

local codes should always be followed.

3. Any submersible motor which is to be run tested

out of the well should be grounded to prevent

possible shock hazard during the test.

NOTE: Always disconnect all power when making

ohmmeter check and while pulling or installing a

pump.

4. The most logical way to “frame” ground a

submersible motor is normally as follows:

a. Run an extra wire with the motor power

conductors. This wire must be sized to meet

Table 250-95 in the U.S. National Electrical

Code. If code information is unavailable, using

the same size wire as the power conductors is

normally adequate.

b. The ground wire may be insulated or bare.

If insulated, it must be green with or without

yellow stripe(s). The ground wire may be

part of, or separate from the supply cable. It

may be continuous or spliced above the pump

along with the supply cable.

c. Connect the green or bare ground wire to the

green ground wire of the submersible motor

lead assembly. If the lead wire assembly does

not include a separate ground wire, attach a

lug to the ground wire and place the lug over

one of the motor studs above the pump intake

flange so the pump will not be cocked. The